Method for reinforcing culvert through inflatable internal mold and self-compacting concrete

A self-compacting concrete and concrete technology, applied in the field of culvert reinforcement, can solve the problems of difficult construction, difficult form support and form removal, limited culvert space, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

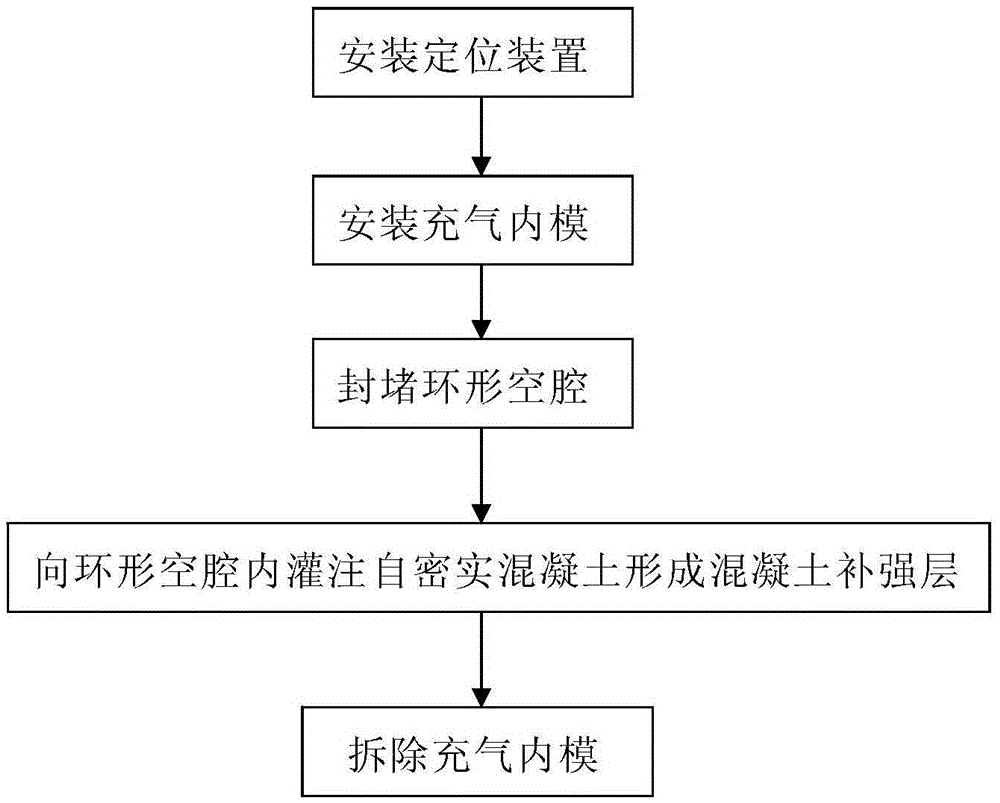

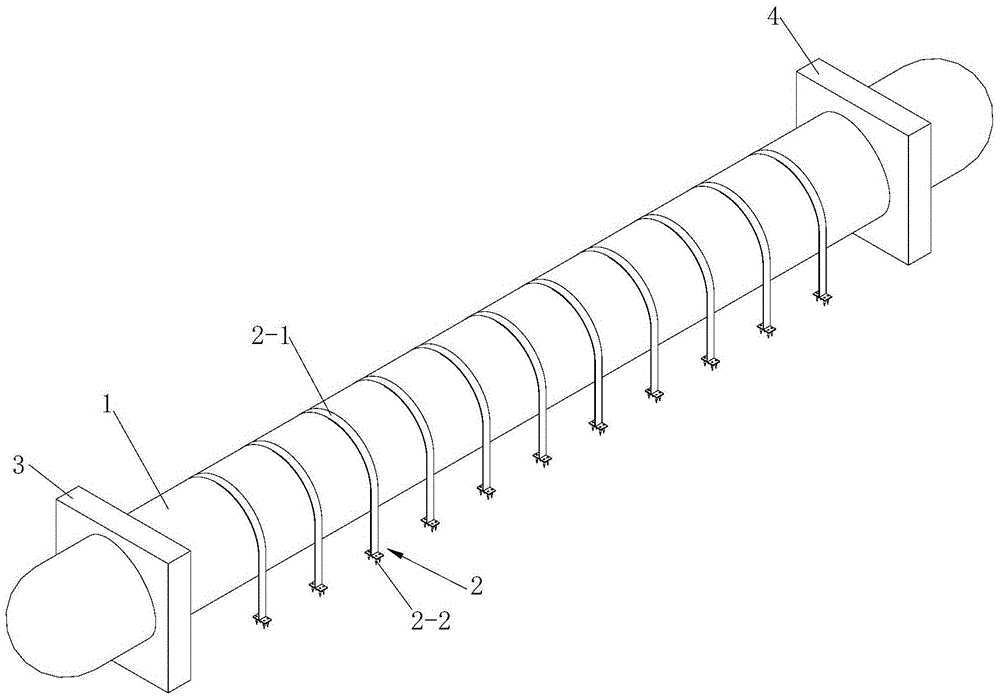

[0045] Such as figure 1 and figure 2 A method of reinforcing a culvert using an inflatable inner form and self-compacting concrete is shown, including the following steps:

[0046] Step 1, install the positioning device 2: a plurality of positioning devices 2 for positioning the inflatable inner mold 1 are arranged longitudinally along the culvert;

[0047] Step 2. Install the inflatable inner mold 1: move the uninflated inflatable inner mold 1 into the culvert, make the inflatable inner mold 1 pass through a plurality of positioning devices 2 in sequence, then inflate the inflatable inner mold 1 and make all the inflatable inner molds 1 Both ends of the inflatable inner mold 1 protrude from the opening of the culvert, and an annular cavity 13 is formed between the inflatable inner mold 1 and the side wall 11 of the culvert;

[0048]Step 3, blocking the annular cavity 13: a first blocking device 3 for blocking one end of the annular cavity 13 is arranged at the water inlet ...

Embodiment 2

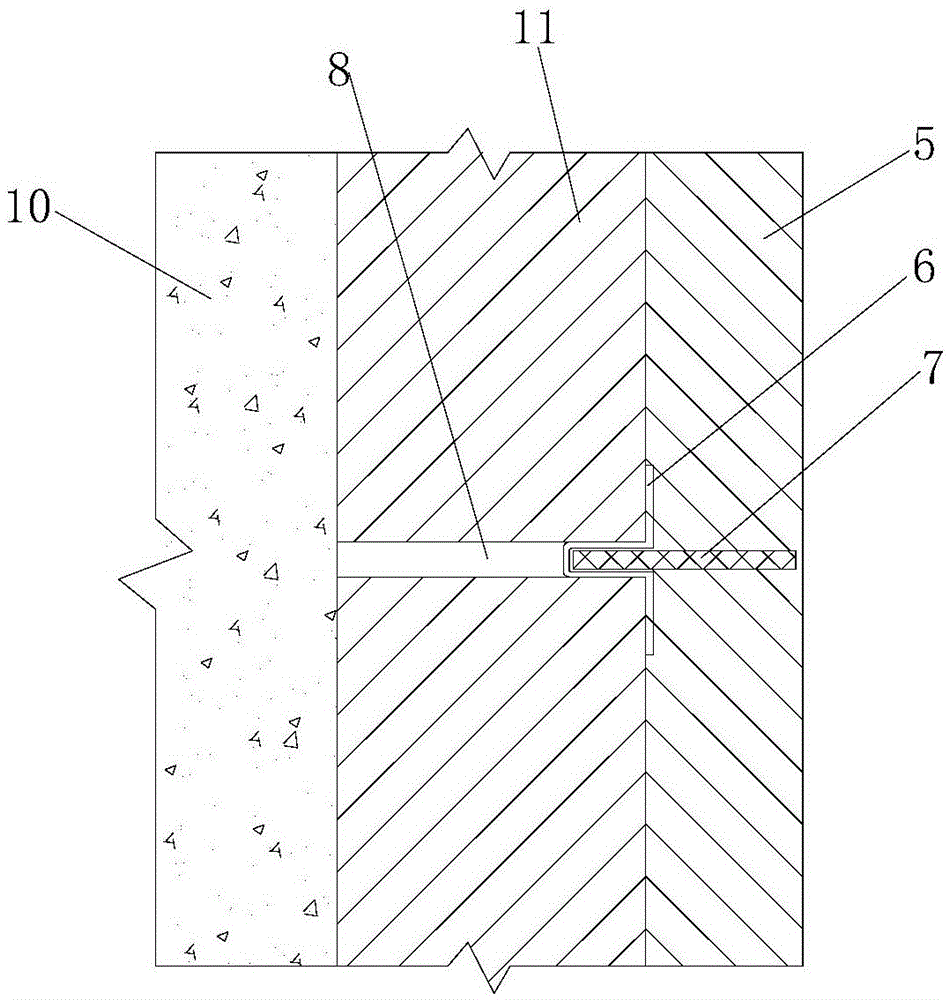

[0063] Such as Figure 6 As shown, the difference between this embodiment and embodiment 1 is that after step five, a pre-crack deformation joint 9 is cut on the concrete reinforcement layer 5 at a position corresponding to the isolation plate 7, and the pre-crack The depth of the deformation joint 9 is smaller than the thickness of the concrete reinforcing layer 5, and the isolation board 7 is a wooden isolation board.

[0064] In this embodiment, by cutting the pre-crack deformation seam 9 on the concrete reinforcement layer 5, and the pre-crack deformation seam 9 corresponds to the position of the isolation plate 7, so that when the concrete reinforcement layer 5 is deformed by an external force , due to the effect of the pre-splitting deformation joint 9 and the wooden isolation board, the concrete reinforcement layer 5 will crack at the pre-splitting deformation joint 9, and at the same time, due to the effect of the water stop 6, the water in the culvert will not flow fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com