Carding method and carding machine for cashmere fibers

A cashmere fiber and carding technology, which is used in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of easy lint loss, large damage to long fibers of bundle fibers, and difficulty in managing the quality and extraction rate of a single machine. and other problems to achieve the effect of improving opening quality and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments are used to illustrate the present invention, but not to limit the protection scope of the present invention.

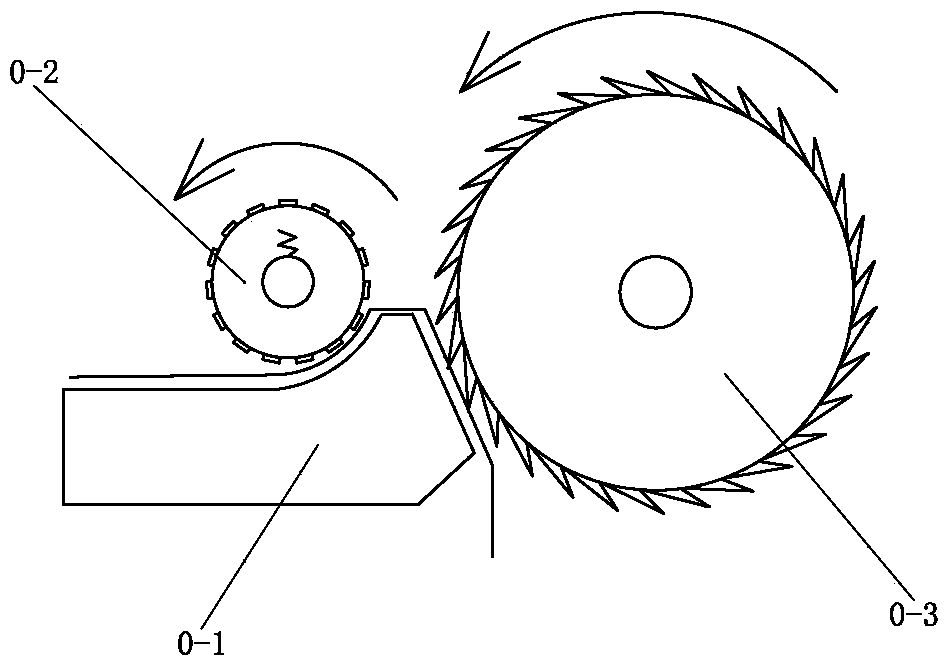

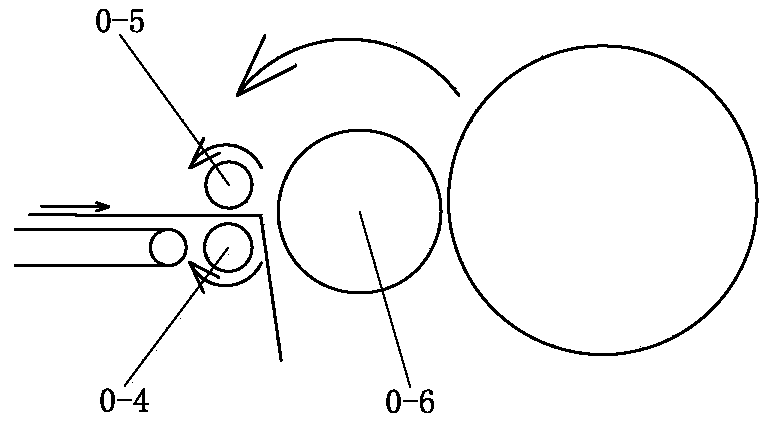

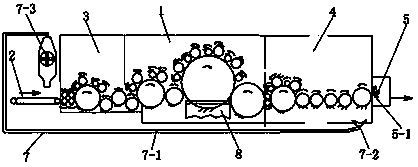

[0042] Such as Figure 9 As shown, this embodiment provides a method for carding cashmere fibers, and this method is suitable for carding washed cashmere raw materials. It includes a pretreatment process for the wool bundle, the pretreatment process includes the step of drawing the fed wool bundle, the step of long-distance tearing of the stretched hair bundle, and the step of stretching the loose hair bundle. The step of preliminary combing to form wool fiber bundles, and the step of opening the wool fiber bundles to remove coarse impurities.

[0043] As the first step to improve this embodiment, such as Figure 3 to Figure 9 As shown, the step of drafting the fed clump is carried out by the drafting mechanism 3-1, 3-2, 3-3, 3-4, and the described process of pulling the clump after drafting The step of loosening is carried out by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com