Electrochemical composite doping method of graphene

A kind of graphene electrochemical and compound doping technology, applied in circuits, electrical components, cable/conductor manufacturing, etc., can solve the weak interaction between small molecule dopants and graphene, limit the practical application of graphene, graphene square resistance Increase and other problems, to achieve the effect of uniform and stable doping effect, low cost and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of graphene electrochemical composite doping method of the present embodiment is as figure 1 As shown, the steps are as follows:

[0022] Step 1, preparing an aqueous electrolyte solution containing 0.1mol / L p-toluenesulfonic acid (TSO) and 0.03mol / L 3,4-ethylenedioxythiophene (EDOT);

[0023] Step 2, using the copper foil 001 grown with graphene 002 as the working electrode, the counter electrode being a platinum plate electrode, and the reference electrode being an Ag / AgCl electrode of saturated potassium chloride;

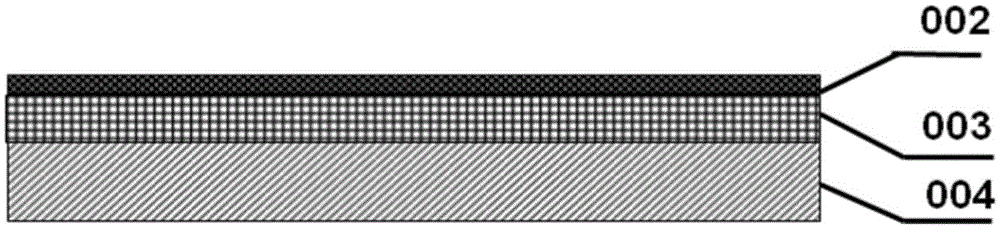

[0024] Step 3, immerse the electrode in the electrolyte solution, select the potential range of -800 ~ 1500mV to polymerize, and electrify for 3 minutes to obtain poly 3,4-ethylenedioxythiophene (PEDOT) film 003, with a thickness of about 5nm, to obtain PEDOT film 003 / graphene 002 / composite structure of growth base copper foil 001, the composite structure is as follows figure 2 shown;

[0025] Step 4, soak the PEDOT film 003 in ethanol, wash it...

Embodiment 2

[0029] A kind of graphene electrochemical composite doping method of the present embodiment is as figure 1 As shown, the steps are as follows:

[0030] Step 1, preparing an aqueous electrolyte solution containing 0.2mol / L p-toluenesulfonic acid (TSO) and 0.05mol / L pyrrole;

[0031] Step 2, using the copper foil 001 grown with graphene 002 as the working electrode, the counter electrode being a platinum plate electrode, and the reference electrode being an Ag / AgCl electrode of saturated potassium chloride;

[0032] Step 3: Immerse the electrode in the electrolyte solution, select the potential range of -200 to 900mV for polymerization, and electrify for 5 minutes to obtain polypyrrole film 003 with a thickness of about 7nm, forming a composite structure of polypyrrole film 003 / graphene 002 / growth substrate copper foil 001 , this composite structure is as figure 2 shown;

[0033] Step 4, immersing the polypyrrole film in deionized water, washing for 3 minutes and drying;

...

Embodiment 3

[0037] A kind of graphene electrochemical composite doping method of the present embodiment is as figure 1 As shown, the steps are as follows:

[0038] Step 1, preparing an aqueous electrolyte solution containing 1mol / L oxalic acid and 0.02mol / L aniline;

[0039] Step 2, using the copper foil 001 grown with graphene 002 as the working electrode, the counter electrode being a platinum plate electrode, and the reference electrode being an Ag / AgCl electrode of saturated potassium chloride;

[0040] Step 3: Immerse the electrode in the electrolyte solution, select the potential range of -500 to 1500mV for polymerization, and energize for 10 minutes to obtain polyaniline film 003 with a thickness of about 10nm, forming a composite structure of polyaniline film 003 / graphene 002 / growth substrate copper foil 001 , this composite structure is as figure 2 shown;

[0041] Step 4, immerse the polyaniline film 003 in isopropanol, clean it for 2 minutes and dry it;

[0042] Step 5: Sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com