High temperature methane bacteria inoculating culture method

A technology for domestication and cultivation of methanogens, which is applied in the field of microbial cultivation, can solve the problems of high energy consumption in engineering operation and low gas production efficiency, and achieves the effects of solving high energy consumption, improving gas production rate and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

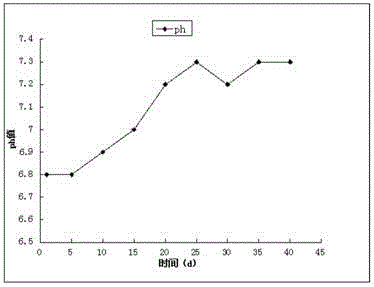

Image

Examples

example 1

[0020] Example 1, according to content of the present invention, propose detailed operation steps below

[0021] (1) Add peptone, glucose, sodium acetate and acetic acid to the anaerobic sludge containing methanogens from the bottom of the river to adjust the pH to 7.2, and carry out anaerobic constant cultivation for 2 days at a temperature of 32°C; The weight ratio is: anaerobic sludge: peptone: glucose: sodium acetate = 3:1:0.5:0.5.

[0022] (2) Add basal medium according to 1 / 4 of the volume of the incubator, and the pH of the medium is 7.2; then pass nitrogen into the incubator to exhaust the air, heat the medium to 25°C, and inoculate according to 10% of the volume of the medium The cultured mixture containing methanogens in step (1) is stirred and mixed evenly with the basal medium;

[0023] The basal medium consists of: sludge, poultry manure and potato dregs are mixed according to the ratio of 500:1500:2000;

[0024] The sludge is black domesticated anaerobic sludge...

example 2

[0029] (1) Add peptone, glucose, and sodium acetate to the anaerobic sludge containing methanogens from the bottom of the river, add acetic acid to adjust the pH to 7.2, and carry out anaerobic constant cultivation at a temperature of 32°C for 4 days. Its weight ratio is: anaerobic sludge: peptone: glucose: sodium acetate=3: 1: 0.5: 0.5;

[0030] (2) According to 1 / 4 of the volume of the incubator, add sludge, poultry manure and potato dregs to mix the basic medium according to the ratio of 1000:500:500, and the pH of the medium is 7.2; then pass nitrogen into the incubator to remove the air , heating the culture medium to 25° C., according to 10% of the culture medium volume inoculation step (1) containing the mixture containing methanogens, and stirring and mixing with the base medium;

[0031] (3) Heat up the culture medium inoculated with methanogens step by step. First, heat the culture medium at 25°C and raise the temperature by 1°C for 1 day and cultivate it for 10 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com