Petroleum hydrocarbon adsorption desulfurization method

A technology for adsorption desulfurization and petroleum hydrocarbons, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc. It can solve the problems of increasing energy consumption and wasting hydrogen, and achieve the effects of saving energy consumption, reducing wear and tear, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the desulfurization adsorbent in the embodiment of the present invention is as follows:

[0053] Will be used as 4.8Kg pseudo-boehmite (production of Shandong Aluminum Factory, Al 2 o 3Content 62.0% by weight), 7Kg of ZnO (Beijing Beihua Fine Chemicals Co., Ltd., chemically pure) and 22.8Kg water mixed beating, add 600g hydrochloric acid (concentration 36% by weight, Beijing Beihua Fine Chemicals Co., Ltd., chemically pure reagent ), the resulting colloid was spray-dried to form particles with a size of 1 mm, and then calcined at 550° C. for 2 h to obtain a microspherical catalyst Cat1. Similarly, catalysts Cat2, Cat3 and Cat4 were obtained, and their compositions are shown in Table 3.

[0054] Table 1

[0055] Liquefied gas raw material properties

Liquefied gas composition, v%

42.64

Acrylic

18.64

21.18

Normal and isobutylene

14.2

Butene-2

3.1...

Embodiment 1

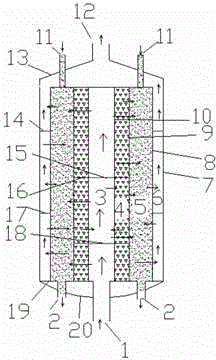

[0068] use as figure 1 The radial flow moving bed reactor shown uses the catalytic cracking gasoline raw material in Comparative Example 1, the pressure is 3.0MPa, and the hydrogen-to-oil ratio is 0.3Nm 3 / m 3 , the reaction temperature is 410°C, and the reaction weight hourly space velocity is 4h -1 , The adsorbent regeneration temperature is 550 °C. The catalyst fixed bed is filled with hydrodesulfurization catalyst RSDS-21, and the catalyst moving bed uses desulfurization adsorbent Cat-1. Product properties and hydrogen consumption are shown in Table 4.

Embodiment 2

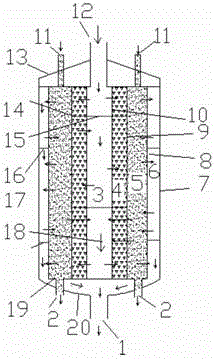

[0070] use as figure 2 The radial flow moving bed reactor shown uses the same FCC gasoline raw material as in Comparative Example 1, the catalyst fixed bed is filled with hydrodesulfurization catalyst RSDS-21, and the catalyst moving bed uses desulfurization adsorbent Cat-2. The pressure of the radial flow moving bed reactor is 2MPa, and the hydrogen-oil ratio is 0.5Nm 3 / m 3 , The reaction temperature is 440°C, and the regeneration temperature of the adsorbent is 550°C. Product properties and hydrogen consumption are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com