A kind of magnesium halide adduct and its preparation method and application

An adduct, magnesium halide technology, applied in the direction of magnesium halide, magnesium chloride, organic chemistry, etc., to achieve the effect of no adhesion, high industrial application value, high polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

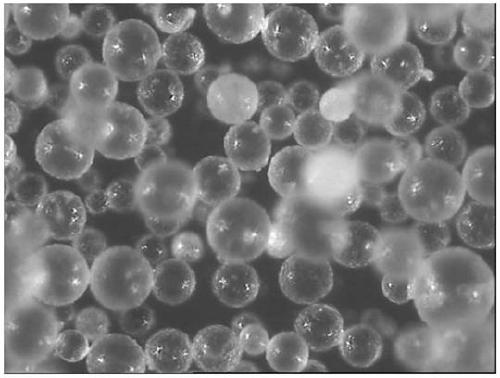

[0140] (1) In a 500mL reactor, add 150mL white oil (commercially purchased from Guangzhou Mingen Petrochemical Co., Ltd., by weight, water content is lower than 50ppm), 30g magnesium chloride containing 0.44wt% moisture (commercially purchased from Fushun City Xinyi Titanium Factory), 50mL absolute ethanol (commercially purchased from Beijing Chemical Plant, with a water content of less than 100ppm by weight) and 1mL 2-methoxybenzoyl chloride (commercially purchased from TOKYOKASEI KOGYO CO.LTD ), heated to 120°C with stirring. After 2 hours of constant temperature reaction, the mixture was pressed into 300 mL of methyl silicone oil (commercially purchased from Dow Corning, with a viscosity of 300 centipoise / 20° C., and a water content of less than 50 ppm by weight) preheated to 120 ° C. Stir for 30 minutes at a speed of 1 / min for emulsification. Then, the emulsified product was injected into 2L of hexane (by weight, water content less than 5ppm) pre-cooled to -30° C. with ni...

Embodiment 2

[0160] (1) Prepare spherical magnesium halide adducts in the same manner as in step (1) of Example 1. The difference is that the magnesium chloride used is magnesium chloride containing 0.65 wt% moisture, and the composition of the prepared magnesium halide adducts is shown in the table 1 listed.

[0161] The magnesium halide adduct was subjected to DSC analysis. In the obtained DSC graph, a melting peak appeared at 97.6° C. and 112.1° C. respectively, and the melting enthalpy value associated with the highest melting peak was 177.3 J / g.

[0162] The X-ray diffraction spectrum of this magnesium halide adduct shows, in the scope of the 2θ diffraction angle of 5-15 °, show to exist in 6.06 ° (14), 8.82 ° (100), 8.98 ° (50), 9.74 ° ( 66), 5 diffraction lines under the diffraction angle 2θ of 11.48°(11); the values in brackets represent the intensity I / I relative to the strongest diffraction line 0 .

[0163] (2) The spherical catalyst component was prepared in the same manner...

Embodiment 3

[0174] (1) In a 500mL reaction kettle, add 150mL of white oil (commercially purchased from Guangzhou Mingen Petrochemical Co., Ltd., with a water content of less than 50ppm by weight), 30g of anhydrous magnesium chloride (commercially purchased from Fushun City Xinyi titanium factory), 50mL absolute ethanol (commercially purchased from Beijing Chemical Plant, the water content is less than 100ppm by weight), 1mL 2-methoxybenzoyl chloride (commercially purchased from TOKYOKASEI KOGYOCO.LTD) and 0.15g water , heated to 120°C with stirring. After 2 hours of constant temperature reaction, the mixture was pressed into 300 mL of methyl silicone oil (commercially purchased from Dow Corning, with a viscosity of 300 centipoise / 20° C., and a water content of less than 50 ppm by weight) preheated to 120 ° C. Stir for 30 minutes at a speed of 1 / min for emulsification. Then, the emulsified product was injected into 2L of hexane (by weight, water content less than 5ppm) pre-cooled to -30° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com