A kind of compound, catalyst solid component containing said compound and catalyst

A solid component and catalyst technology, applied in the field of olefin polymerization, can solve the problem that the electron donor compound cannot meet the needs, and achieve the effect of good comprehensive performance and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

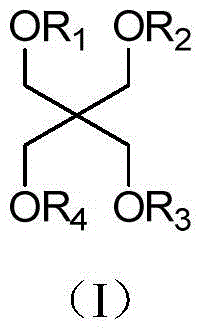

Image

Examples

Synthetic example

[0058] Synthesis of compound 12,2-bis(methoxymethylene)-1,3-dimethoxypropane:

[0059] 1) Synthesis of 2-((2-phenyl)-1,3-dioxcyclohexyl)-1,3-propanediol:

[0060] 54.4g of pentaerythritol (Mw=136.15, 0.4mol) was dissolved in 500mL of water. Raise the temperature to 40°C, add 42.4g benzaldehyde (Mw=106, 0.4mol) and 2mL concentrated hydrochloric acid, and stir for 6 hours. The reaction system was left standing overnight. Suction filtration, add 800mL water and 0.5g potassium carbonate to the filter cake, stir and raise the temperature to dissolve, cool and crystallize. After filtration, the crude product was dried under vacuum at 75°C. Crude toluene was recrystallized, and the final product was 72.6 g, with a yield of 81%.

[0061] 1 H NMR (CDCl 3 / TMS,300MHz)δ(ppm):3.56(s,4H,-C(CH 2 Oh) 2 ),3.76,3.79(s,4H,-C(CH 2 O) 2 CH-),5.44(s,1H,phCH-),7.37-7.39(m,5H,C 6 h 5 CH-).

[0062] 2) Synthesis of 2-((2-phenyl)-1,3-dioxcyclohexyl)-1,3-dimethoxypropane:

[0063] 20g of ...

Embodiment 1

[0091] Magnesium alkoxide preparation:

[0092] In a 1L reactor equipped with a stirrer, a reflux condenser, a thermometer, and a burette, after fully replacing with nitrogen, 550 mL of ethanol, 10 mL of isopropanol, and 0.68 g of iodine were dissolved in the reactor. After stirring, the temperature was raised until reaching the reflux temperature of the reaction system. Then add magnesium powder 32g successively; React until no hydrogen is discharged. Then wash, filter and dry to obtain a bulk density of 0.25g / cm 3 , 147 g of magnesium alkoxide with an average particle diameter (D50) of 47.0 μm.

[0093] Preparation of solid catalyst component:

[0094] Take 10g of the alkoxymagnesium carrier prepared above, 50mL of toluene and 2.5g of the internal electron donor (compound 1) to prepare a suspension; add 40mL of toluene and four Titanium chloride 60mL, then add the prepared suspension into the kettle, raise the temperature to 80°C, keep the temperature constant for 1 hour...

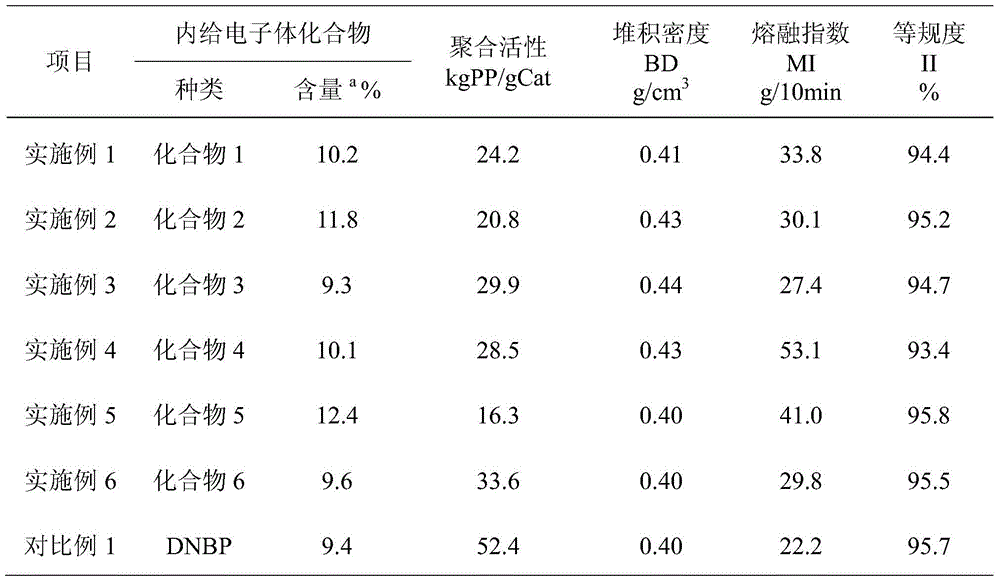

Embodiment 2-6

[0098] The steps are the same as in Example 1, except that the internal electron donors are replaced with compounds 2-6 in the preparation of the solid catalyst component, and the dosage is 2.5 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com