A kind of polypropylene product and preparation method thereof

A polypropylene and product technology, applied in the field of polypropylene products and their preparation, can solve the problems of polymer molecular weight drop, brittleness, catalyst activity reduction, etc., and achieve good stereospecificity, high hydrogen sensitivity, and high polymerization activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

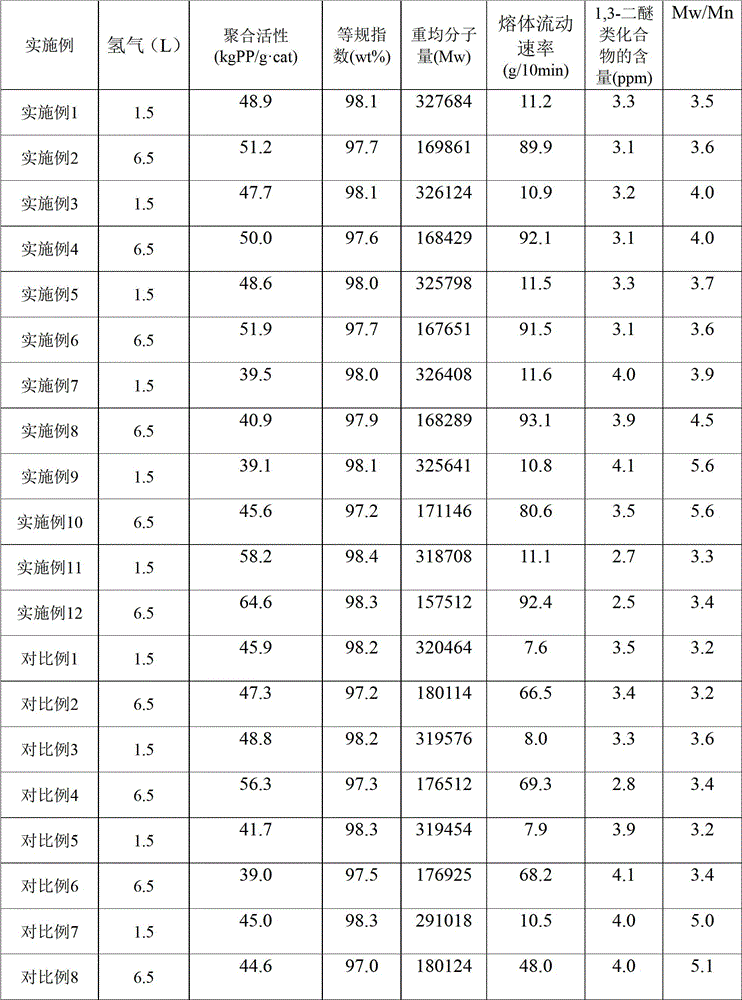

Examples

preparation example Construction

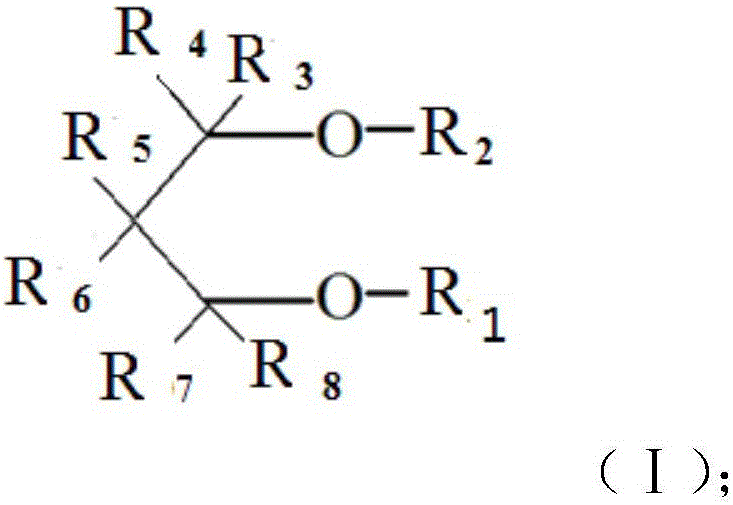

[0021] According to the preparation method of polypropylene product of the present invention, the method comprises polymerizing propylene or a mixture of propylene and ethylene and / or α-olefin in the presence of a catalyst under olefin polymerization conditions to obtain a polypropylene product, the catalyst Contains a solid component, an alkylaluminum compound and an external electron donor compound, the solid component contains magnesium, titanium, halogen and an internal electron donor compound, the internal electron donor compound contains a 1,3-diether compound , wherein, the solid component is prepared by the following method:

[0022] (1) reacting the magnesium-containing support with the first titanium compound, and adding an internal electron donor during one or more time periods before, during and after the reaction of the magnesium-containing support with the first titanium compound;

[0023] (2) The product obtained in step (1) is subjected to solid-liquid separati...

Embodiment approach

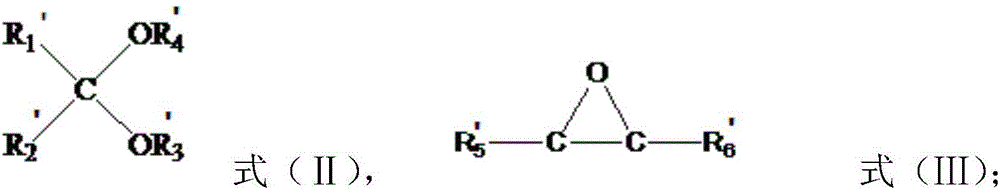

[0031] In the present invention, the magnesium-containing carrier can be various magnesium-containing solid substances commonly used in the field of olefin polymerization catalysts, usually containing magnesium halide and alcohol compounds; in one embodiment, the magnesium-containing carrier contains the general formula: Magnesium halides of MgXY, compounds with the general formula ROH, compounds with the general formula R'OH, and dihydrocarbyloxyhydrocarbon compounds; wherein, X in the general formula MgXY is halogen, Y is halogen, C 1 -C 14 Alkyl, C 1 -C 14 Alkoxyl, C 6 -C 14 Aryl or C 6 -C 14 The aryloxy group; in the general formula ROH, R is C 1 -C 8 Alkyl or C 3 -C 8 Cycloalkyl; in the general formula R'OH, R' is C 16 -C 24 The alkyl or aralkyl group; the structure of the dihydrocarbyloxy hydrocarbon compound is shown in formula (II), and the structure of the oxirane compound is shown in formula (III):

[0032] Formula (Ⅱ), Formula (Ⅲ);

[0033] Among th...

preparation example 1

[0067] This preparation example is used to prepare the catalyst solid component used in the preparation method of the polypropylene product of the present invention.

[0068] (1) Preparation of magnesium-containing carrier

[0069] In a 1.6L reactor, add 200ml white oil, 8.0g (0.08mol) magnesium chloride, 3g (0.01mol) octadecyl alcohol, 95ml (1.6mol) ethanol, 9.8ml (0.08mol) 2,2-dimethoxy base propane, heated to 90°C with stirring. After reacting at constant temperature for 1 hour, the mixture was stirred at high speed (400 rpm) for 30 minutes to disperse for emulsification. Add 35 ml (0.45 mol) of epichlorohydrin to the above emulsified product, react for half an hour, press filter, wash the press filter product 5 times with hexane, and vacuum dry to obtain the magnesium-containing carrier Z1.

[0070] The average particle diameter (D50) of the magnesium-containing carrier Z1 is 57 microns, and the particle size distribution ((D90-D10) / D50) is 0.8. The particle morphology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com