MEMS (Micro-Electromechanical System) hermetic packaging structure and method

A packaging structure and packaging method technology, applied in the direction of microstructure devices, manufacturing microstructure devices, processing microstructure devices, etc., can solve the problems of unsatisfactory reliability results and cost reduction, and achieve good sealing, low cost, and The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. For convenience of description, the components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments. The above or upper side of the structure or surface includes the case where there are other layers in the middle.

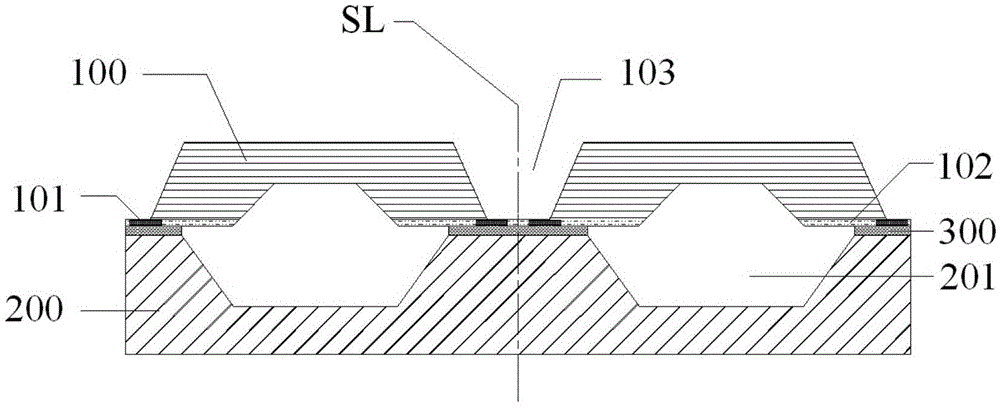

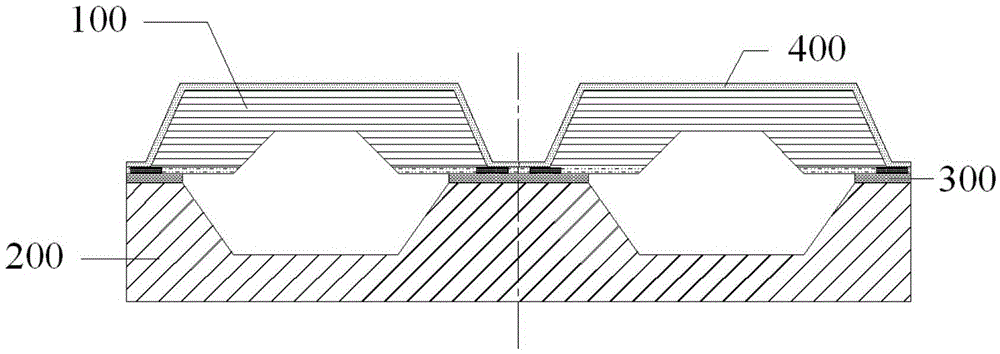

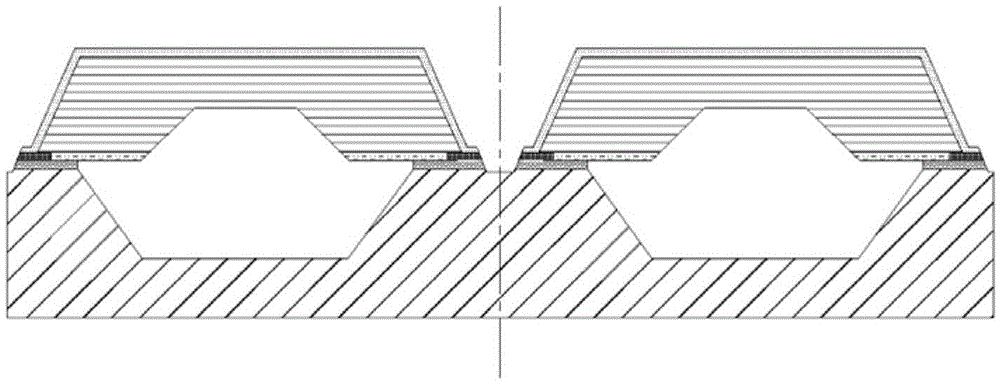

[0037] like Figure 7 and Figure 8 As shown, a kind of MEMS hermetic packaging structure, comprises a MEMS chip 100 with welding pad 101 and a cover 200 for sealing this MEMS chip on the edge of a functional surface, the edge of the functional surface of the MEMS chip is connected with the cover The front edge of the MEMS chip is bonded together by a polymer layer 300 of a certain width and thickness, the back side of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com