Chip fracture image detection method

An image detection and chip technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as unsatisfactory use requirements and slow speed, and achieve high accuracy and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

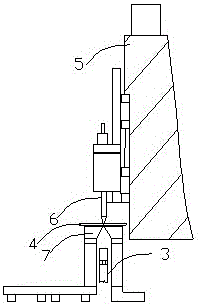

[0019] refer to Figure 2-5 As shown, in order to have a better understanding and recognition of the present invention, now enumerate preferred embodiment and cooperate picture description as follows:

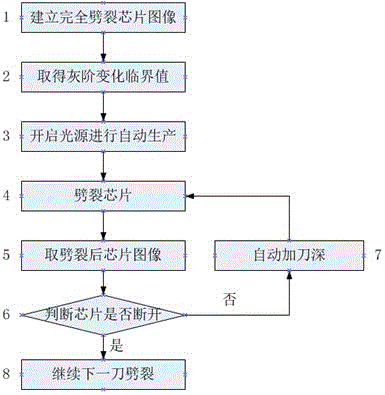

[0020] The present invention is an image detection chip unbroken method, which is applied to a wafer splitter 5 to determine whether the chip 4 is broken after the chip is split. The specific method steps include:

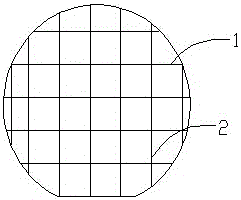

[0021] Step 1: Establish a completely split chip image, wherein, the chip image just after the chip 4 is completely split is collected by the image collector 3, and the acquisition of the chip image after the complete split needs to be deepened step by step until it is just split , at this time the image collected by the image collector 3 is the chip image after the complete splitting that we need.

[0022] Step 2: Obtain the critical value of the gray scale change, wherein, through the image processing unit, obtain the gray scale change critical value of the compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com