Stacker and reclaimer and its rotary platform

A technology of rotary platform and reclaimer, which is applied in the direction of conveyor, loading/unloading, transportation and packaging, etc. It can solve the problems of small size and unable to install a larger size central hopper, so as to improve the conveying efficiency and the conveying effect. Good, structurally balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

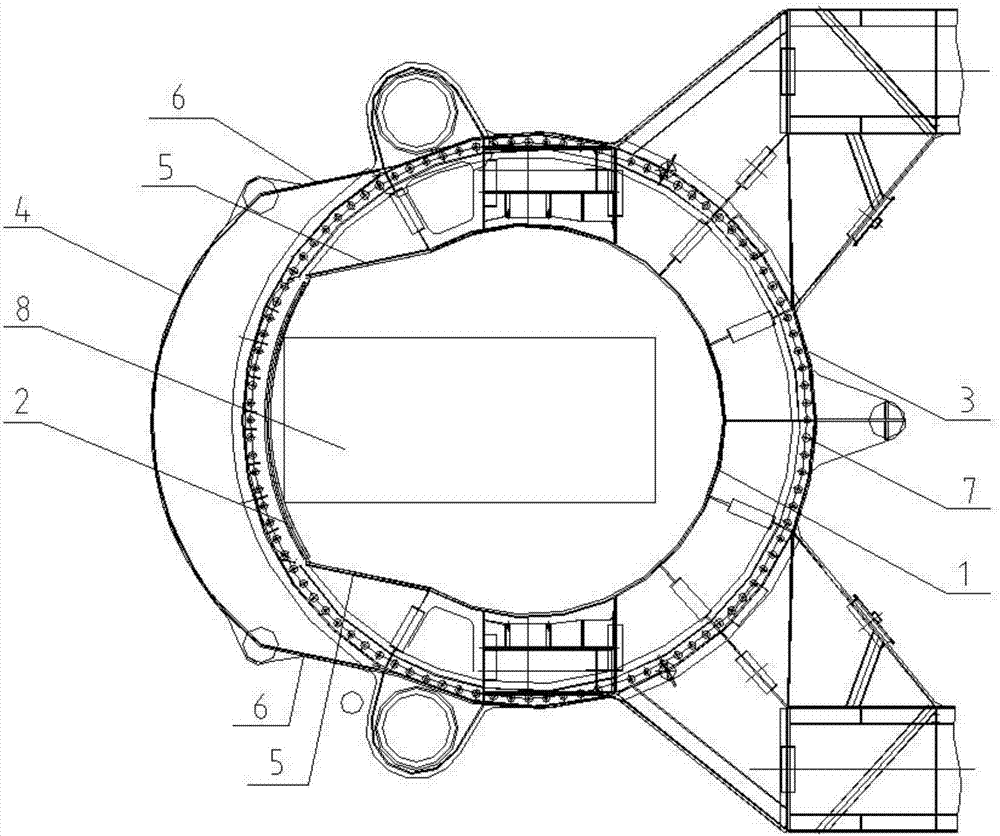

[0033] figure 1 A top view of the slewing platform provided for Embodiment 1 of the present invention. Such as figure 1 As shown, the slewing platform of a stacker-reclaimer provided in this embodiment includes an annular body, the inner contour of the annular body forms a hollow installation cavity of the central hopper 8 that matches the inner contour, and the annular The bottom end of the body is rotatably connected to the top of the door frame through a slewing bearing 7; The second arc wall 2 on one side of the extension direction and the first connecting wall 5 connecting the first arc wall 1 and the second arc wall 2 form a closed contour, and the first arc wall 1 and the second arc wall 2 form a closed contour. The second arc wall 2 is centered on the center of rotation of the rotary platform, and the centers of the first arc wall 1 and the second arc wall 2 are basically located on the center line of the cantilever frame. The diameter of the second arc wall 2 is gr...

Embodiment 2

[0047]A stacker-reclaimer provided in this embodiment has the rotary platform of Embodiment 1. In addition to the above-mentioned rotary platform, the stacker-reclaimer of this embodiment also includes a door frame, a rectangular central hopper 8 and a cantilever frame. The rectangular central hopper 8 is a rectangular pyramid-shaped hopper with a cross section. The upper end face of the pyramid forms the feed inlet of the central hopper 8, and the lower end face forms the discharge outlet of the central hopper 8. The discharge outlet is smaller than the feed inlet, so that the center The front and rear sidewalls of the hopper 8 arranged along the extending direction of the cantilever frame are tapered, and the center of the discharge port coincides with the center of rotation. During the rotation of the cantilever frame, the blanking is accurate, safe and effective; the central hopper 8 is set It is pyramid-shaped with a rectangular cross-section. Compared with the circular ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com