Device for removing SO3 through flue injection of dry powder adsorbent

An adsorbent, SO3 technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as poor reliability, large differences in device systems, and complex implementation forms of slurry injection devices, and achieve stable and reliable performance and feeding speed. Fast, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

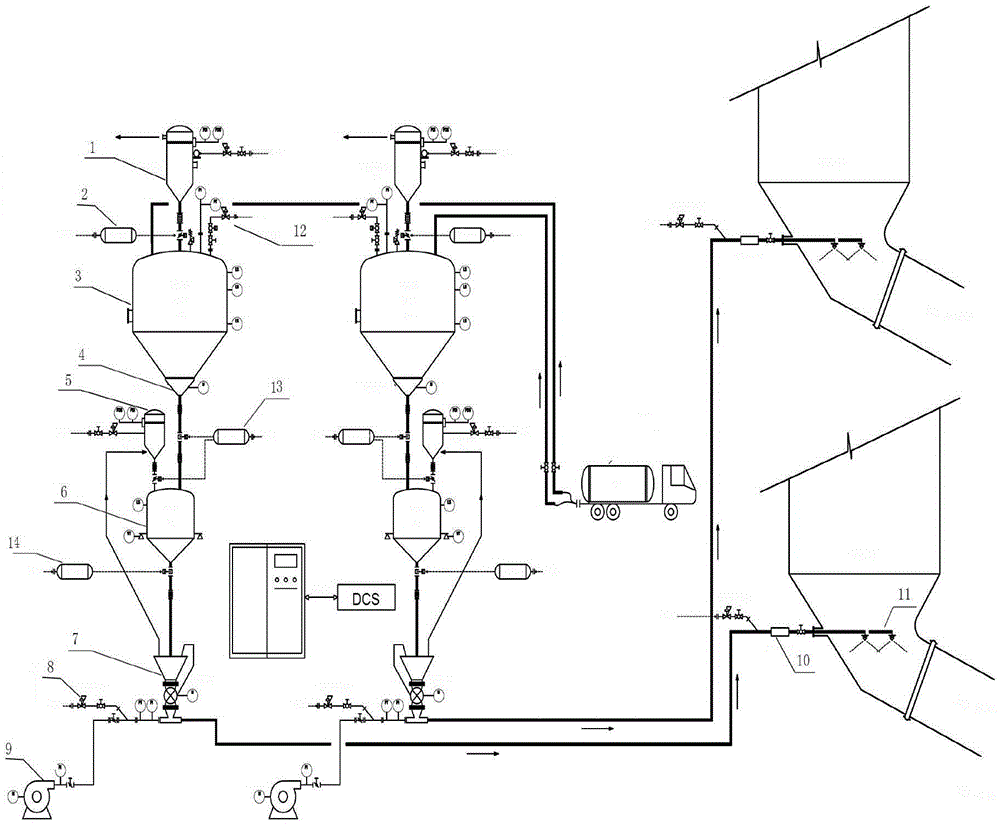

[0026] Taking a certain 600MW coal-fired unit as an example below, the present invention will be further described in conjunction with the accompanying drawings.

[0027] This embodiment provides a dry powder adsorbent flue injection to remove SO 3 equipment such as figure 1 shown, including:

[0028] Storage tank 3, is used for storing dry powder alkaline adsorbent;

[0029] A weighing tank 6 communicates with the storage tank 3;

[0030] The storage tank 3 communicates with the weighing tank 6 through the pneumatic feeder 4 , and the powder storage tank 3 passing into the weighing tank 6 is controlled through the pneumatic feeder 4 .

[0031] The rotary valve 7 is arranged under the weighing tank 6, and is used to make the material powder enter the air delivery pipe;

[0032] Distributor 10, used for splitting the material powder conveyed by the air-flow conveying pipe;

[0033] The nozzle 11 extends into the flue and communicates with the rotary valve 7 through the distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com