Mechanically-adjustable-clearance semi-active radial sliding bearing

A radial sliding, semi-active technology, applied in sliding contact bearings and other directions, can solve problems such as different rotation centers, vibration, noise, etc., and achieve the effects of increasing bearing damping, high control accuracy, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

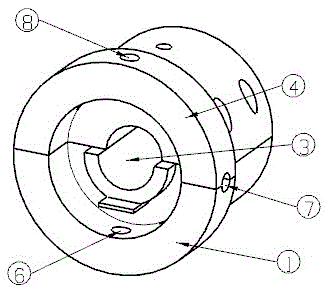

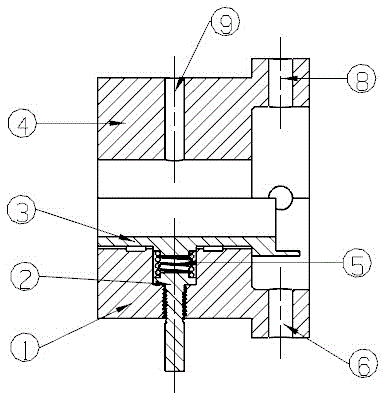

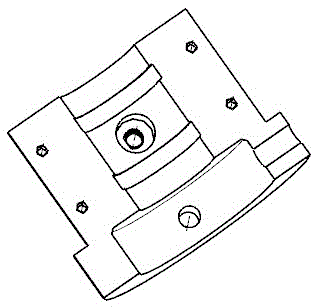

[0014] Such as Figure 1 to Figure 4 As shown, a mechanically adjustable gap semi-active radial sliding bearing includes a lower tile cover 1, a regulator 2, a lower tile 3, an upper tile 4, a spring 5, a hydraulic system and a signal acquisition system, and the lower tile cover 1 Cooperate with the upper tile 4 to install and fix, the lower tile 3 is installed on the lower tile cover 1, the inner surface of the lower tile cover 1 is provided with a groove, the bottom of the groove is provided with a threaded hole, and the thread of the regulator 2 The rod is installed in it, and the bottom of the lower tile 3 has a boss, which is installed in the groove of the lower tile 1 and can move in a small distance in the radial direction; the spring 5 is installed in the groove of the lower tile 1 , one end of the spring 5 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com