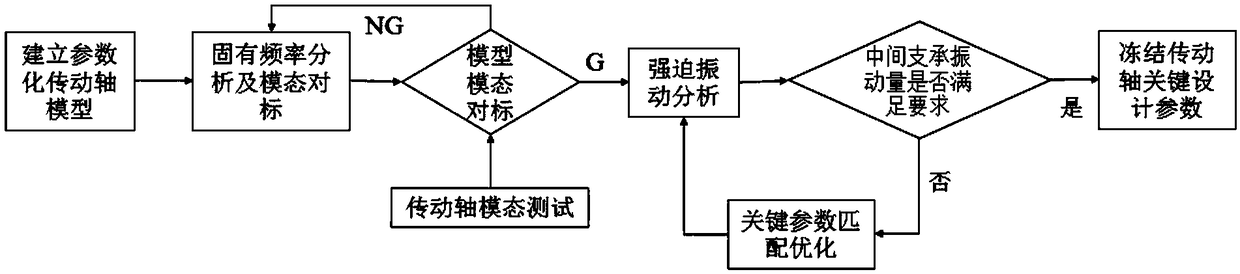

An analysis method for optimizing the vibration quantity of the intermediate support of a transmission shaft when an automobile starts

A technology for intermediate support and vehicle start, applied in the field of power transmission, can solve the problems of shortening the development cycle, reducing the development cost, and taking a long time, so as to achieve the effect of shortening the development cycle, reducing the development cost and avoiding high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

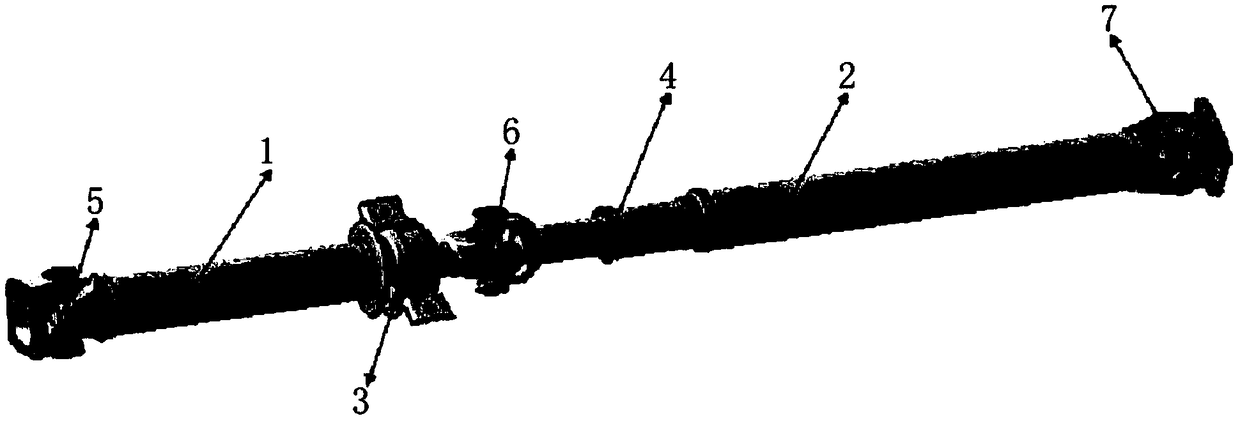

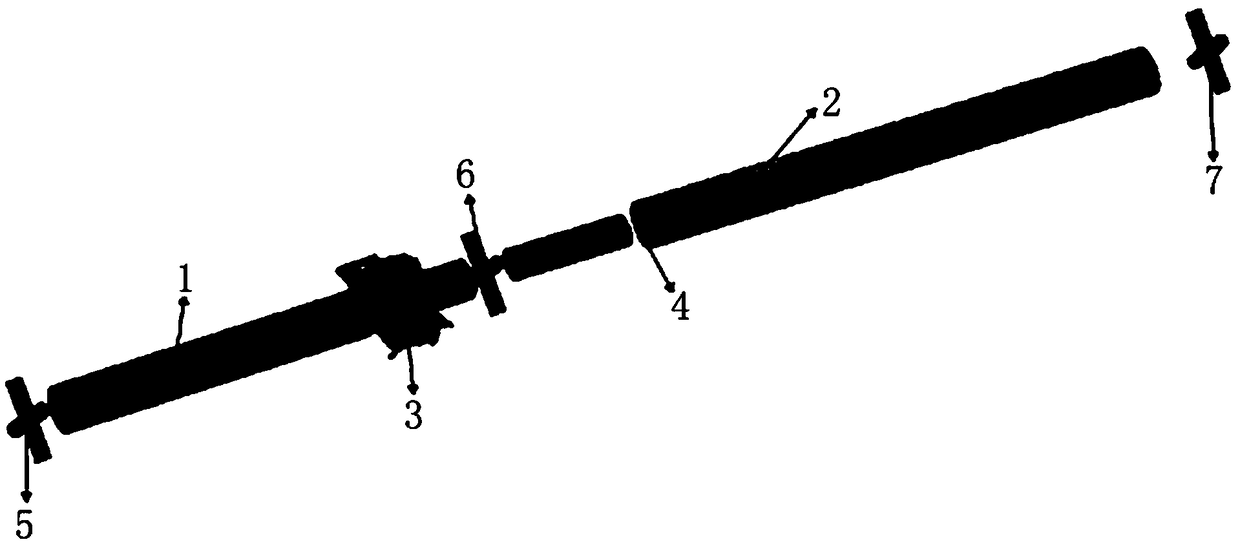

[0044] Embodiment 1: The transmission shaft described in this embodiment is a two-stage transmission shaft, such as figure 2 As shown, the two-stage drive shaft includes a front shaft tube 1, a rear shaft tube 2, an intermediate support 3, a sliding fork 4, a first cross shaft 5 arranged at the end of the front shaft tube, and a cross shaft 5 arranged between the front and rear shaft tubes. The second cross shaft 6 between and the third cross shaft 7 arranged at the end of the rear axle tube 2, such as image 3 As shown, in step 1, the key parameters such as the stiffness of the transmission shaft intermediate support, the phase angle and position of the cross shaft are parameterized, and the corresponding assembly connection relationship is established according to the actual vehicle state.

[0045] Such as Figure 4 As shown, in step 2, the measured frequency value of the transmission shaft is 30.47 Hz along the Y direction of the whole vehicle, and 29.99 Hz along the Z di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com