Damping bearing seat

A bearing seat and bearing technology, applied in the field of sliding parts, can solve the problems of large bearing force, small internal space, long working time, etc., and achieve the effects of slowing bearing vibration, slowing lateral vibration and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

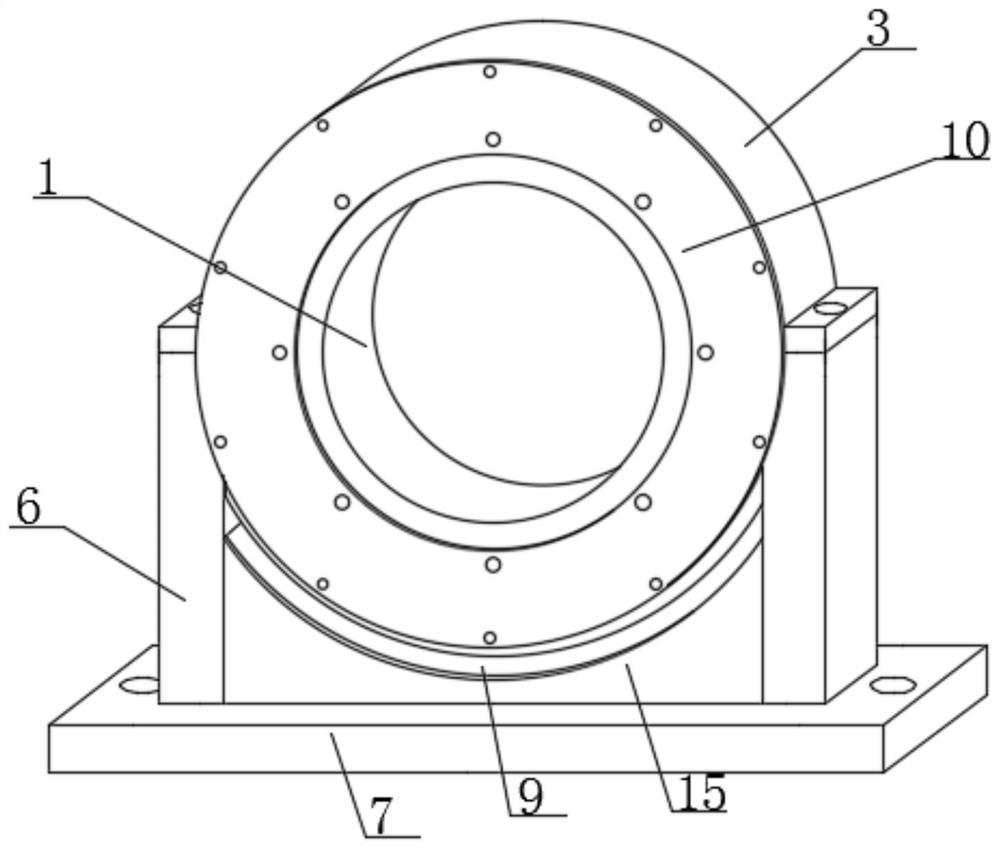

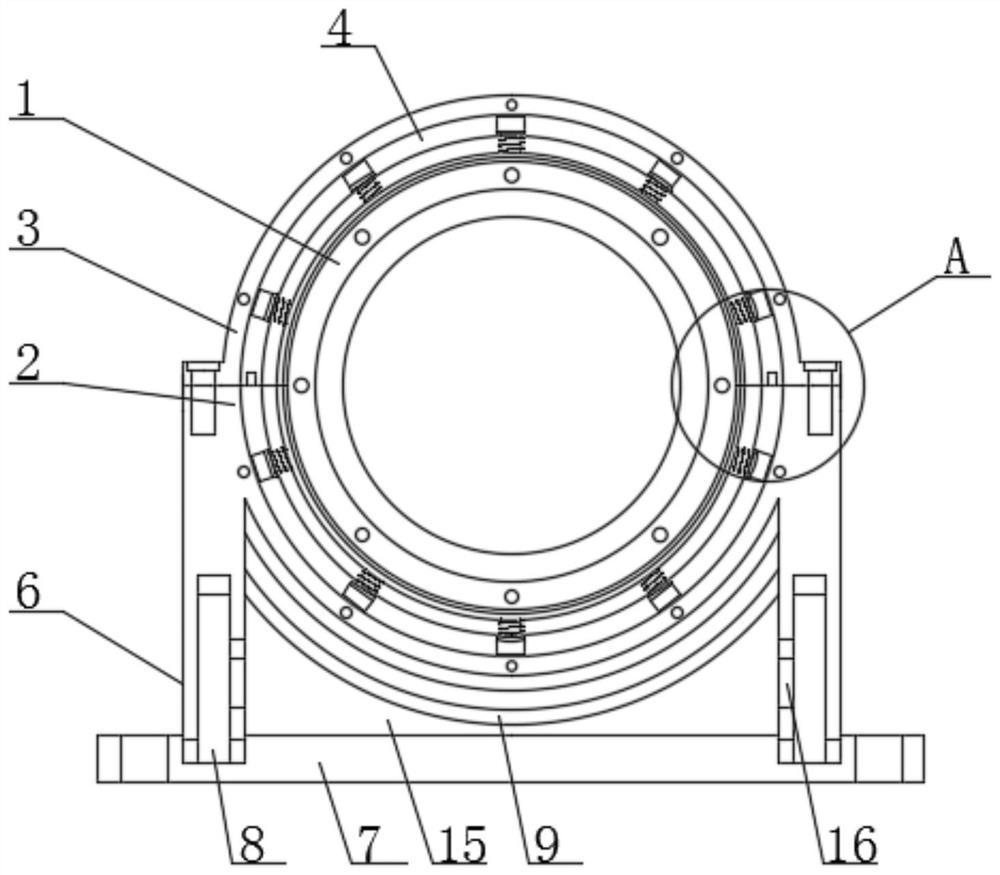

[0029] Such as figure 1 As shown, a shock-absorbing bearing seat includes a bearing body 1, a bearing seat 2 is provided at the bottom of the outer surface of the bearing body 1, and a bearing cover 3 is provided on the top of the bearing seat 2 and located at the top of the outer surface of the bearing body 1. The inner outer surface of the bearing seat 2 and the bearing cover 3 and the outer surface of the bearing body 1 are provided with a positioning ring 4, the outer surface of the positioning ring 4 and the outer surface of the shaft body 1 is provided with a positioning snap ring 5, and the bottom of the bearing seat 2 Support rods 6 are arranged on both sides of the outer surface, bases 7 are arranged between the bottom outer surfaces of the corresponding support rods 6, and slide bars 8 are arranged on both sides of the outer surface of the top of the base 7 and inside the support rods 6, Magnetic strips 9 are provided between the inner sides of the corresponding supp...

Embodiment 2

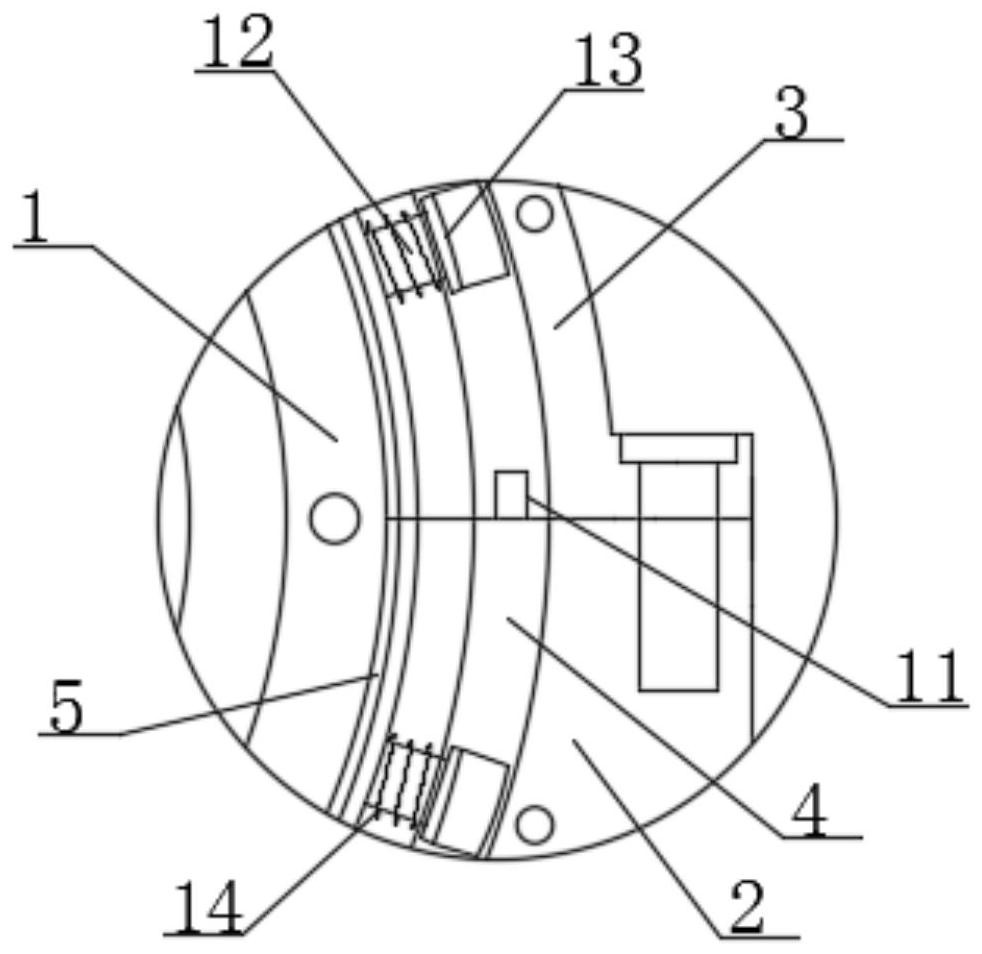

[0033] On the basis of Embodiment 1, such as figure 2 , 3 4. The outer side of the positioning ring 4 shown in 4 is fixedly connected with the inner side of the bearing seat 2 and the inner side of the bearing cover 3. The positioning ring 4 is in the shape of a semicircle, and the outer surfaces of both sides of the positioning ring 4 at the bottom are provided with inserts 11. The insertion strip 11 is fixedly connected with the positioning ring 4 at the bottom, and grooves corresponding to the insertion strip 11 are provided on both outer surfaces of the positioning ring 4 at the top.

[0034] There are multiple groups of inserting rods 12 arranged between the inner outer surface of the positioning ring 4 and the outer outer surface of the positioning clip 5, the inserting rods 12 are fixedly connected to the outer outer surface of the positioning clip 5, and the bottom of the inserting rods 12 is positioned at the positioning The inside of the ring 4 is provided with a l...

Embodiment 3

[0037] On the basis of embodiment one and embodiment two, such as Figure 5 , 6As shown, the outer surface of the bottom of the bearing seat 2 is fixedly connected to the magnet bar 9 on the top, and the corresponding magnet bars 9 are all arc-shaped, and the corresponding magnet bars 9 are of the same polarity, and the bottom outer surface of the magnet bar 9 at the bottom is A magnet base 15 is arranged between the top outer surfaces of the base 7, and the magnet base 15 is fixedly connected with the magnet bar 9 at the bottom and the top outer surface of the base 7.

[0038] The both sides outer surface of magnet seat 15 is tangent to the inner outer surface of support bar 6, and connecting block 16 is arranged between the both sides outer surface of magnet seat 15 and the inner outer surface of slide bar 8, and connecting block 16 and magnet seat 15 and The support rods 6 are all fixedly connected, and the inside of the support rod 6 is provided with a chute corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com