Efficient electrostatic spinning oil-water separation fiber membrane

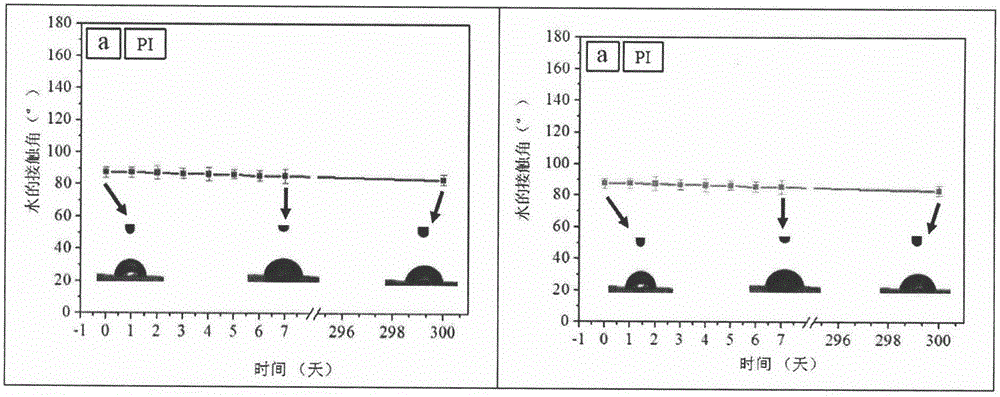

A technology of oil-water separation and electrospinning, applied in electrospinning, immiscible liquid separation, liquid separation, etc., can solve the problems of low separation efficiency, poor strength, secondary pollution, etc., and achieve high separation efficiency and high separation The effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

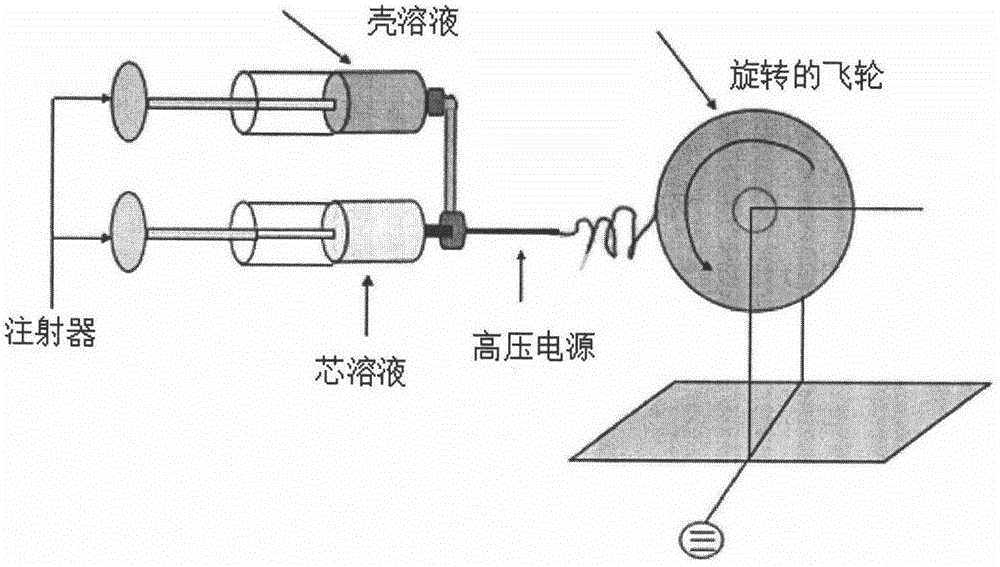

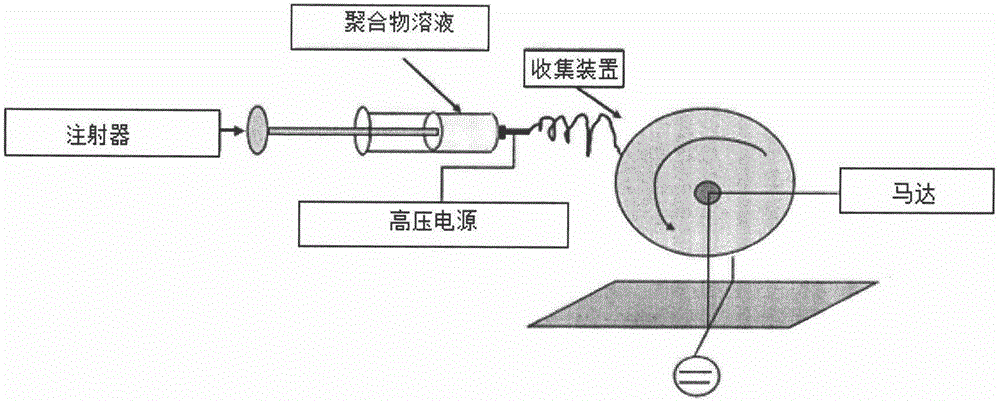

Method used

Image

Examples

Embodiment Construction

[0026] The preparation method of the preparation method of the efficient superhydrophobic and superoleophilic oil-water separation nanofiber membrane comprises the following process steps:

[0027] (1) synthesis of PAA;

[0028] Add biphenyltetracarboxylic dianhydride (BPDA) and p-phenylenediamine (PDA) respectively 2.9422g and 1.0814g (molar ratio 1:1) into a dry four-necked flask equipped with a mechanical stirrer, a thermometer, and a nitrogen gas inlet and outlet tube, and mix well ; Under strong mechanical stirring, add 40ml of DMAc, react at -15°C-5°C for 24 hours, and then terminate the reaction to obtain PAA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com