Center device with hardness-strengthened conical cusp

A sharp tip and hardness technology, applied in the field of thimble devices, can solve problems such as cracks or lacerations, insufficient hardness of the cone tip, etc., and achieve the effect of improving hardness and having deep industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

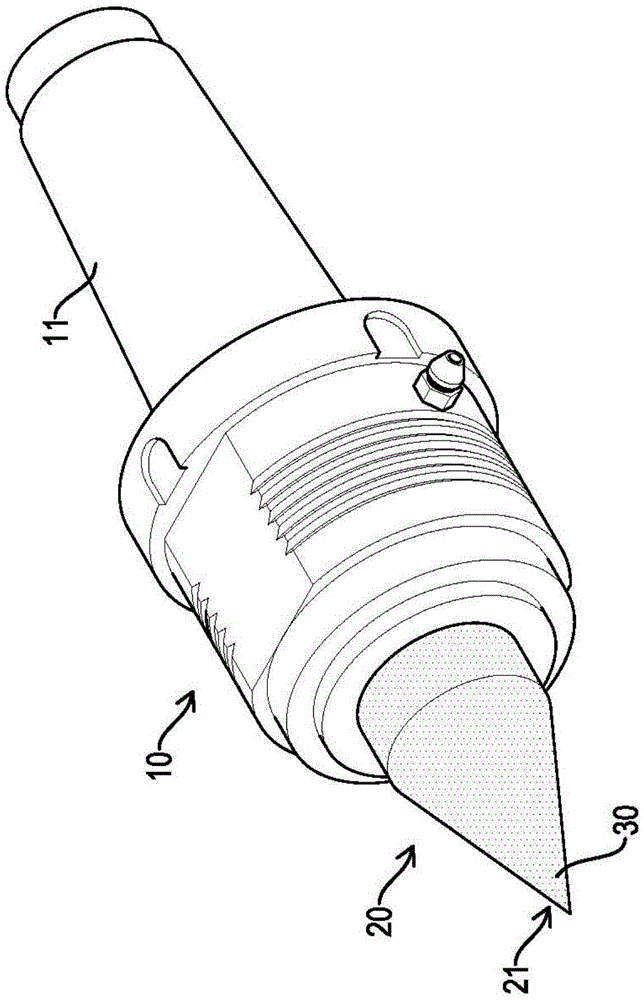

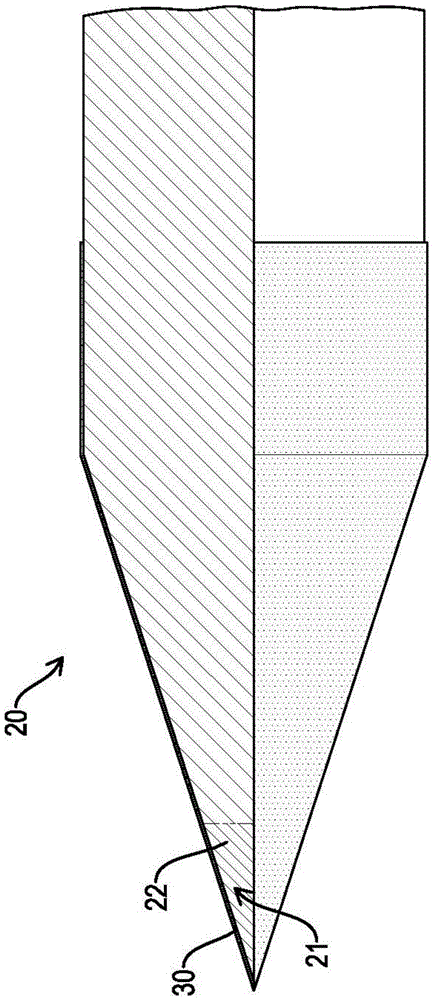

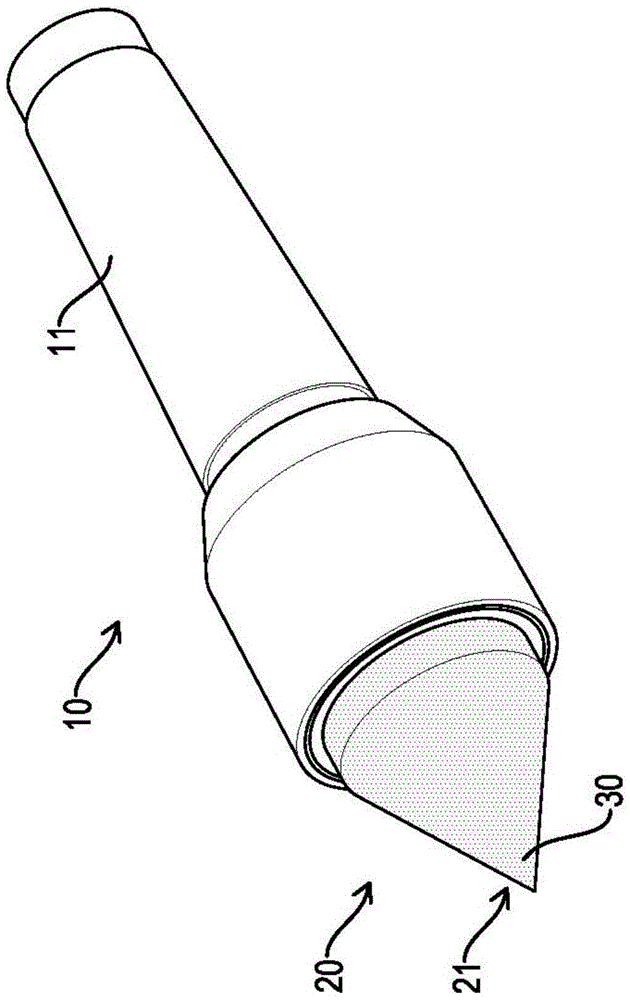

[0034] Such as figure 1 and figure 2 Shown is a preferred embodiment of the present invention applied to a fixed rotary thimble, the thimble device has a core handle 10 and a core 20 combined with the core handle 10 in a transferable form; wherein, the core handle 10 A tapered columnar tapered shank 11 is provided, so that the center handle 10 can be installed and combined with the machine tool tailstock with the tapered handle 11; the center 20 is made of high-speed steel or tungsten steel, etc. It has a cone shape and can be used to abut against the workpiece, and heat treatment can be used to increase the hardness of the steel at the cone point 21 to form a heat treatment hardened portion 22 .

[0035] The present invention adopts PVD (Physical Vapor Deposition, physical vapor deposition) coating technology, deposits and forms a film-shaped coating layer 30 on the surface of the cone tip 21 of the top core 20, preferably, the coating layer 30 can be further extended to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com