An ultra-fast cooling process and coiling method for ultra-thick gauge hot-rolled coils

An ultra-fast cooling and hot-rolled coil technology, applied in the ultra-fast cooling process and coiling, steel plate rolling field, can solve the problems of few hot-rolled coils, etc., to improve coiling stability, no additional cost, improve The effect of tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

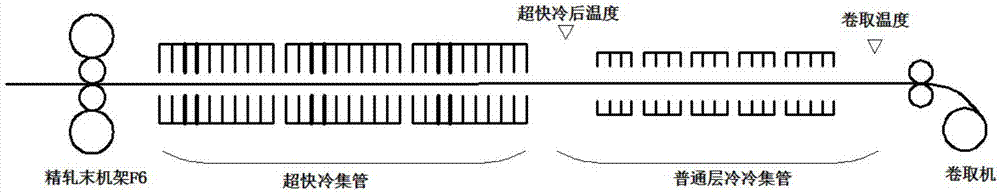

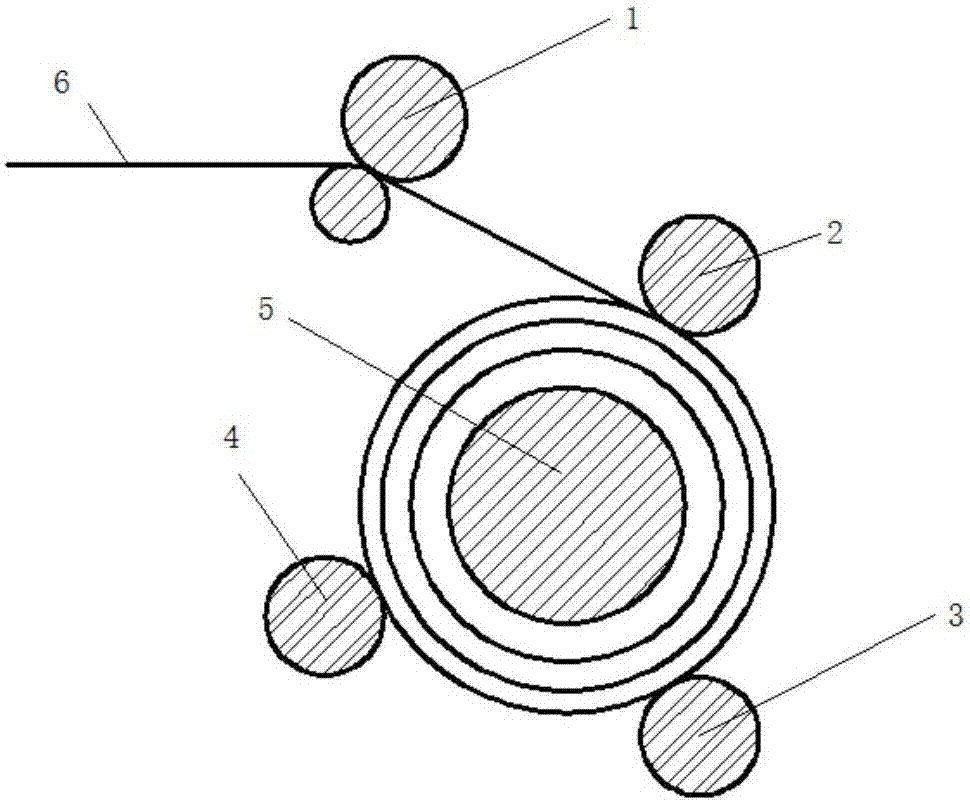

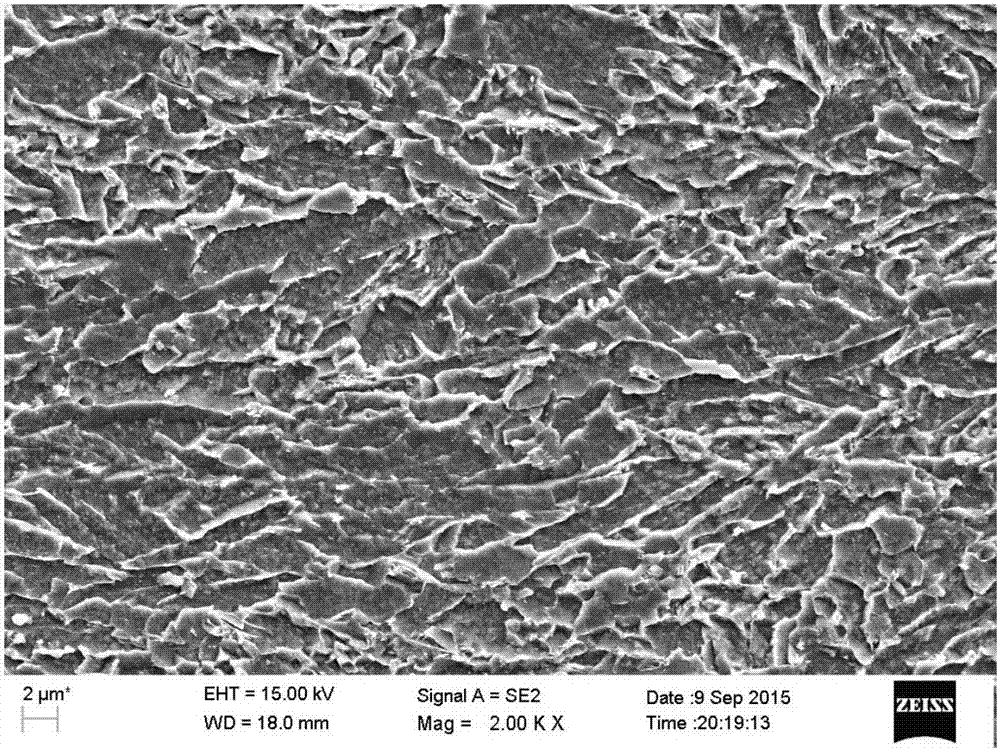

[0035] Taking the pipeline steel strip X70 with a thickness of 25.4mm as an example, such as figure 1 As shown, the strip steel 6 passes through 3 sets of ultra-fast cooling headers, and the total flow rate of the headers is 7500m 3 / h, the ultra-fast cooling outlet temperature of the strip is cooled to 500-550°C, then air-cooled, the air-cooling time is 2s, and then cooled by a conventional cooling header, the coiling temperature is 400-450°C, and the following is obtained: image 3 The strip steel 6 shown has fine ferrite grains with an average grain size of about 5 μm, thereby ensuring the drop weight performance. figure 2 Intermediate coiler pinch roll 1 guides the strip steel 6, the first coiling aid roll 2, the second coiling aiding roll 3 and the third coiling aiding roll 4 are equidistantly arranged on the outer circumference of the coiler drum 5, 25.4mm thick X70 pipeline The strip steel 6 enters between the three helper rolls 2-4 and the coiler drum 5 .

[0036]Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com