Rapid mounting and dismounting mechanism used for distribution chute replacing device and distribution chute replacing system

A distributing chute, fast technology, applied in the direction of bell and funnel arrangement, etc., can solve the problems of complex action, economic loss, poor repeatability and other problems in the replacement process, and achieve the effect of shortening the wind break time, improving production efficiency and shortening the replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

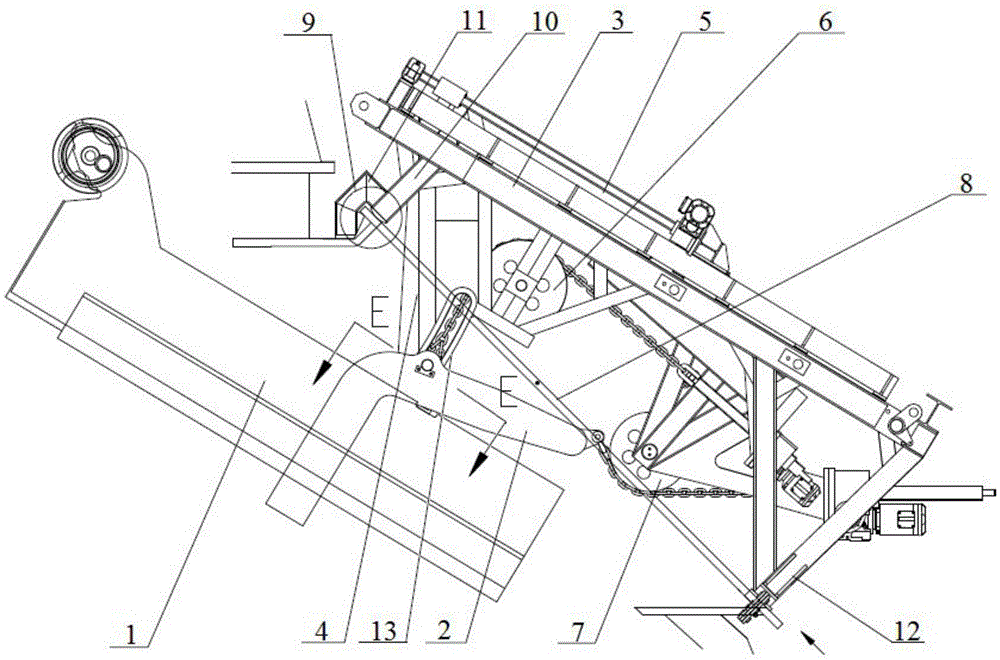

[0029] Such as Figure 1-Figure 4 , an embodiment of the present invention provides a quick replacement device for a distribution chute, including a clamping mechanism 2 and a driving mechanism, wherein:

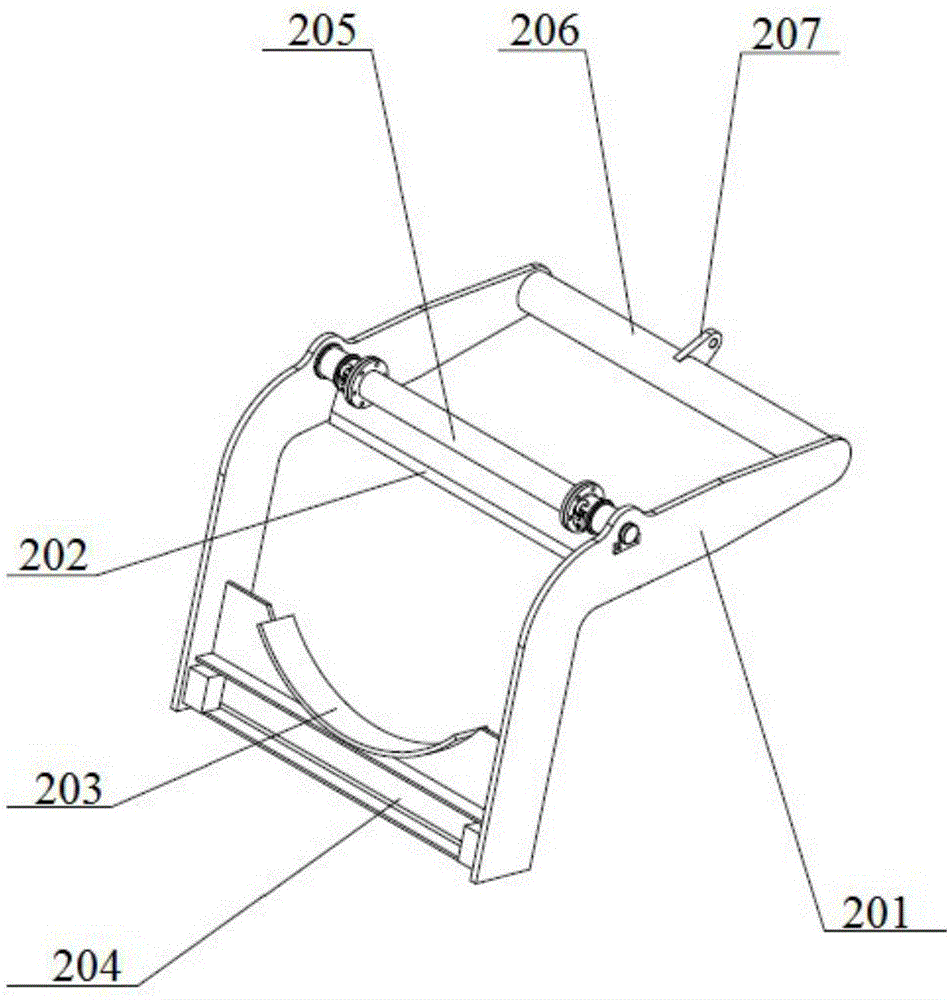

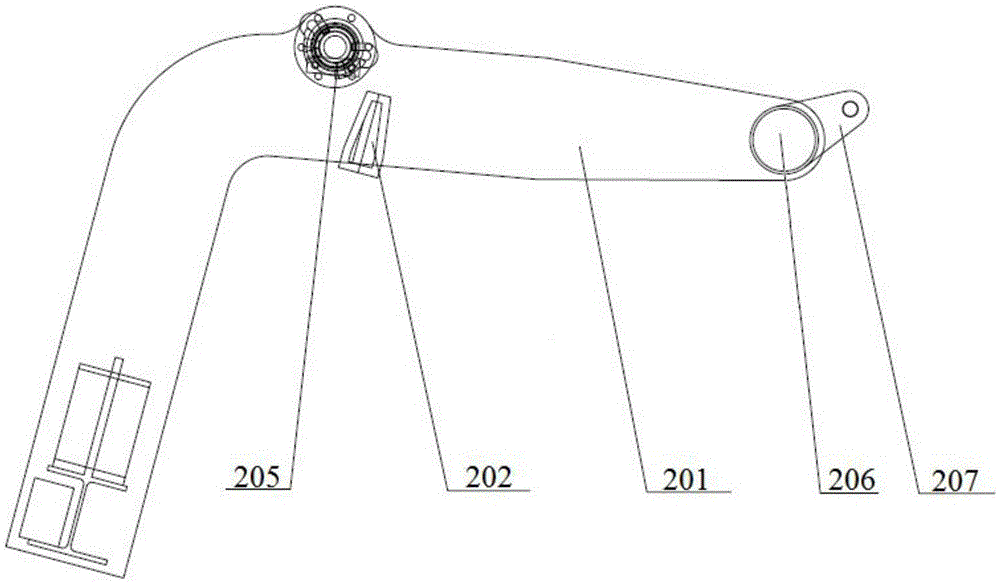

[0030] The clamping mechanism 2 includes a lower pressing plate 202, an upper lifting plate 203, a rotary shaft 205, a tail beam 206 and two bending plates 201, the two bending plates 201 are in the shape of a factory and are parallel to each other, and the two bending plates 201 are opposite to each other in parallel. The folded plates 201 each have a first end, a second end and a bent portion, the two first ends are connected by the tail beam 206, and the two second ends are connected by the lifting plate 203, The two ends of the lower pressing plate 202 are fixedly connected with the two bent plates 201 respectively, and the two bent plates 201 are rotatably connected with the rotating shaft 205. The lifting plate 203, the rotating shaft 205, The tail beam 206 and the tw...

Embodiment 2

[0042] Such as figure 1 and Figure 6-Figure 9, the embodiment of the present invention provides a quick assembly and disassembly mechanism of the distribution chute replacement device, which is used to install the distribution chute replacement device to the inspection door 8 or remove it from the inspection door 8. The distribution chute replacement device adopts the one provided in the first embodiment The cloth chute quick change device. The inspection door 8 includes a door leaf, a door frame 801 and a supporting frame 802 . The quick assembly and disassembly mechanism includes a locking structure 9 and a locking structure, the locking structure 9 hangs and installs the fixing bracket 3 on the inspection door 8, and the locking structure locks the fixing bracket 3 It is locked on the inspection door 8 and can be quickly unlocked. The hook structure 9 includes two sets of hook assemblies, the two sets of hook assemblies are arranged on both sides of the center line of t...

Embodiment 3

[0049] The embodiment of the present invention relates to a distribution chute replacement system, including a distribution chute replacement device and a quick assembly and disassembly mechanism for installing the distribution chute replacement device on the inspection door 8 or removing it from the inspection door 8; the above-mentioned distribution chute replacement device adopts the embodiment The quick assembly and disassembly mechanism of the distribution chute replacement device provided by the first embodiment adopts the quick assembly and disassembly mechanism of the distribution chute replacement device provided by the second embodiment, and will not be repeated here.

[0050] Embodiments of the present invention at least achieve the following beneficial effects:

[0051] (1) The quick replacement device for the distribution chute provided by the embodiment of the present invention can quickly fix and clamp the distribution chute 1 by using the clamping mechanism 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com