Dripping and pulverizing control device and dripping and pulverizing treatment method for steelmaking reducing slag

A technology of control device and treatment method, which is applied in the field of steel slag treatment, can solve the problems of low site utilization rate, impact on slag steel recovery, high treatment cost, etc., and achieve the effect of improving the on-site operation environment, reducing labor intensity and controlling dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

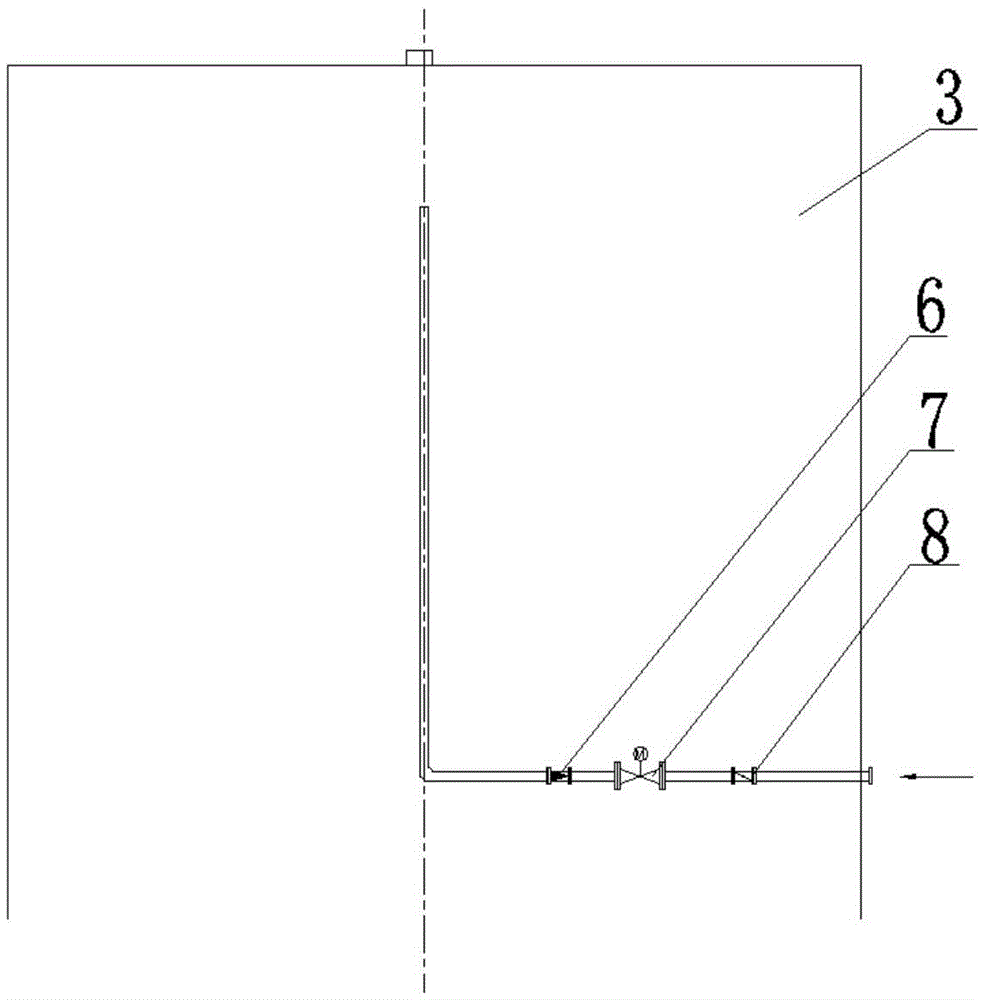

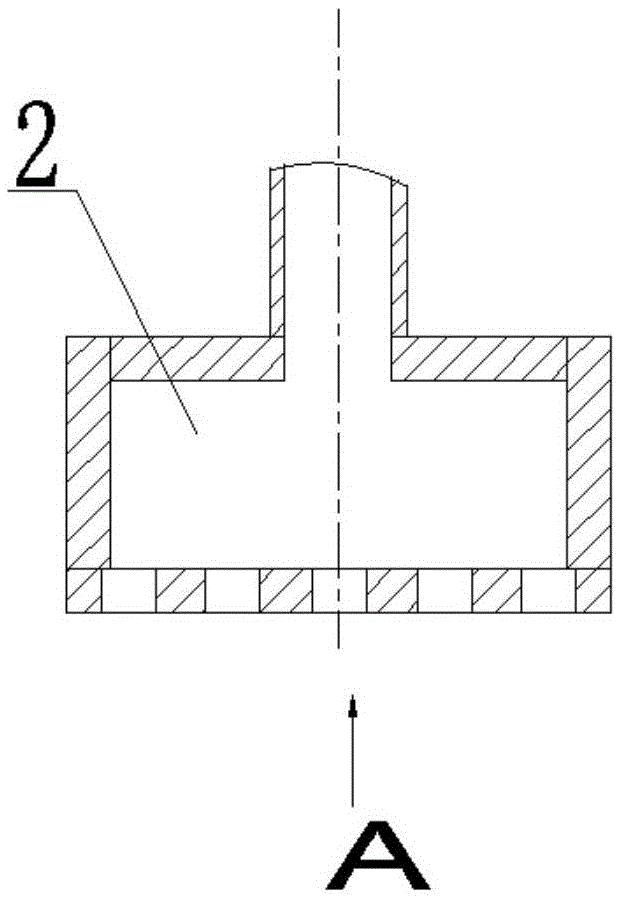

[0027] Such as Figure 1-Figure 4 As shown, the drip pulverization control device for steelmaking reducing slag of the present invention includes a slag tank 1, a nozzle 2, a water inlet pipe 4, a dust cover 3 and a PLC control processor. Among them, the slag tank 1 is a tank body with an upper opening as a cover. The dust cover 3 covers the slag tank 1 and the nozzle 2. The nozzle 2 is placed above the slag tank 1. The spraying area of the nozzle 2 corresponds to the tank mouth of the slag tank 1. . Water inlet pipe 4 runs through dust cover 3, and one end of water inlet pipe 4 is connected with water source, and its other end is connected with shower head 2, provides cooling water for shower head 2. The pipe section where the water inlet pipe 4 is placed outside the dust cover 3 is provided with an electromagnetic flowmeter 6 , an electric regulating valve 7 and an electric valve 8 . The electromagnetic flowmeter 6, the electric control valve 7 and the electric valve 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com