Device for preparing biodiesel from microalgae biomass by means of ester exchange and then extraction

A biodiesel and biomass technology, applied in biofuels, petroleum industry, fat production, etc., can solve the problems of unsuitability for industrial production and application, high oil extraction rate, etc., and achieve broad industrial application prospects, safe, simple and good production operation. The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

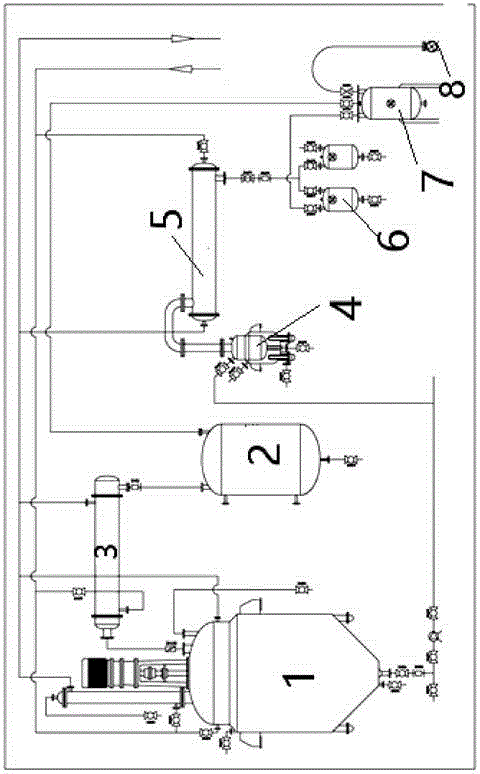

[0024] Such as figure 1 The shown microalgae biomass is first transesterified and then extracted to prepare biodiesel, including a multifunctional kettle 1, a solvent storage tank 2, a solvent condenser 3, a distillation kettle 4, a methyl ester condenser 5, a biodiesel storage tank 6, Air balance tank 7, vacuum pump 8.

[0025] The top of the multifunctional kettle 1 is connected with one end of the solvent condenser 3 , the other end of the solvent condenser 3 is connected with the solvent storage tank 2 , and the solvent storage tank 2 is also connected with the air balance tank 7 . The bottom of the multifunctional kettle 1 is connected with the top of the still 4, and the top of the still 4 is also connected with the methyl ester condenser 5, and the methyl ester condenser 5 is connected with the biodiesel storage tank 6, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com