Wear-resistant, oil-resistant and ageing-resistant control cable

A technology for controlling cables and aging resistance, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low strength, poor wear resistance, poor aging resistance and oil resistance, etc., to improve the tensile strength. and tear strength, excellent abrasion resistance, and the effect of shortening the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

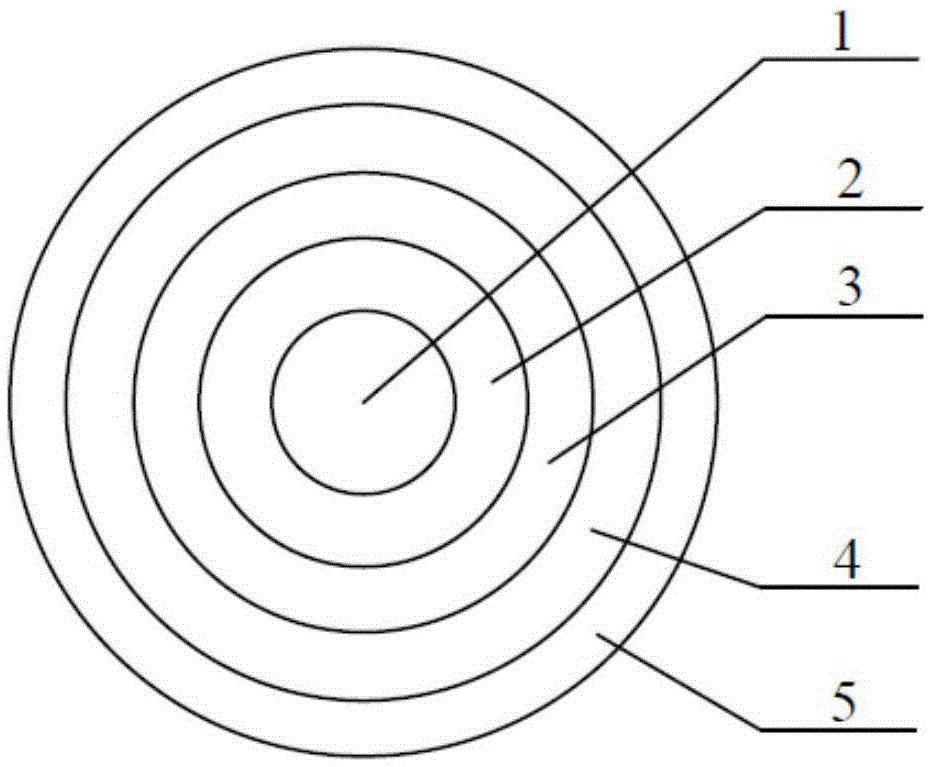

[0021] figure 1 It is a structural schematic diagram of the wear-resistant, oil-resistant and aging-resistant control cable of the present invention, referring to figure 1 , a wear-resistant, oil-resistant and aging-resistant control cable proposed by the present invention, comprising a conductor 1, a polyvinyl chloride insulating layer 2 is coated on the outside of the conductor 1, and an inner liner is coated on the outside of the polyvinyl chloride insulating layer 2 Layer 3, the inner lining layer 3 is covered with an armor layer 4, and the armor layer 4 is covered with an outer sheath 5, wherein the outer sheath 5 is made of a modified natural rubber composite material Prepared, the raw materials of the modified natural rubber composite material include by weight: 100 parts of natural rubber, 50 parts of styrene-butadiene rubber, 15 parts of butadiene rubber, 18 parts of epoxidized natural rubber, and 10 parts of modified composite filler , 3.5 parts of stearic acid, 0.5...

Embodiment 2

[0024] refer to figure 1 , a wear-resistant, oil-resistant and aging-resistant control cable proposed by the present invention, comprising a conductor 1, a polyvinyl chloride insulating layer 2 is coated on the outside of the conductor 1, and an inner liner is coated on the outside of the polyvinyl chloride insulating layer 2 Layer 3, the inner lining layer 3 is covered with an armor layer 4, and the armor layer 4 is covered with an outer sheath 5, wherein the outer sheath 5 is made of a modified natural rubber composite material Prepared, the raw materials of the modified natural rubber composite material include by weight: 100 parts of natural rubber, 20 parts of styrene-butadiene rubber, 35 parts of butadiene rubber, 10 parts of epoxidized natural rubber, and 25 parts of modified composite fillers , 2 parts of stearic acid, 2 parts of zinc oxide, 0.5 parts of sulfur, 1.5 parts of 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.5 parts of accelerator, 2.5 parts of a...

Embodiment 3

[0027] refer to figure 1 , a wear-resistant, oil-resistant and aging-resistant control cable proposed by the present invention, comprising a conductor 1, a polyvinyl chloride insulating layer 2 is coated on the outside of the conductor 1, and an inner liner is coated on the outside of the polyvinyl chloride insulating layer 2 Layer 3, the inner lining layer 3 is covered with an armor layer 4, and the armor layer 4 is covered with an outer sheath 5, wherein the outer sheath 5 is made of a modified natural rubber composite material Prepared, the raw materials of the modified natural rubber composite material include by weight: 100 parts of natural rubber, 32 parts of styrene-butadiene rubber, 29 parts of butadiene rubber, 14 parts of epoxidized natural rubber, and 20 parts of modified composite fillers , 2.5 parts of stearic acid, 1.6 parts of zinc oxide, 0.9 parts of sulfur, 1.2 parts of 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.3 parts of accelerator CZ 0.2 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com