A kind of polyimide nanocomposite material containing naphthalene structure and its preparation method and application

A technology of nanocomposite materials and polyimide, which is applied in the field of material science to achieve the effect of simple preparation process, various preparation processes and low condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

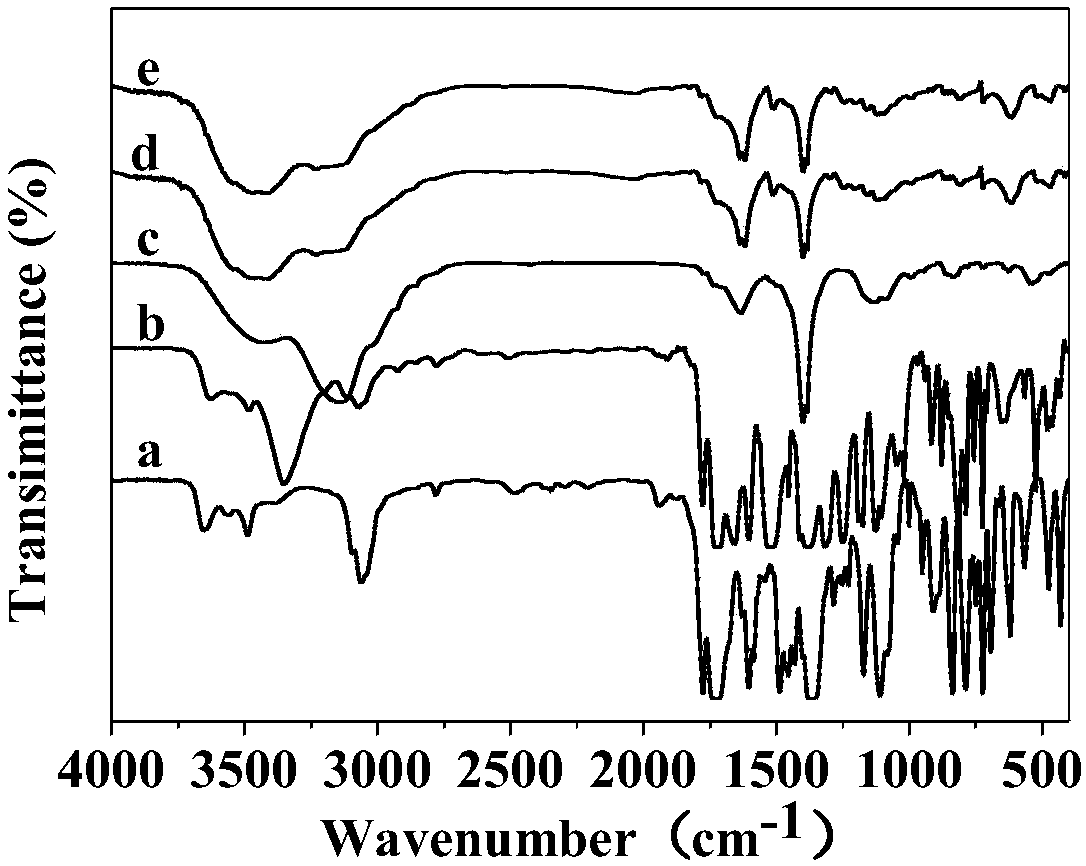

[0037]At room temperature, under argon atmosphere, 0.20g mica (Mica) was sonicated in (41ml) N,N-dimethylformamide for 1h, and then 3.1040g (0.01mol) 4,4'-(naphthalene-2 ,7-diyl)dianiline (NPDA) and 2.1812g (0.01mol) 1,2,4,5-Benzenetetracarboxylic anhydride (1,2,4,5-pyromellitic dianhydride, PMDA) were added to N,N- In dimethylformamide, the solid content was 15%, and the reaction was stirred for 6 hours to obtain a homogeneous and viscous polyamic acid / mica composite glue. Scrape-coat the polyamic acid / mica composite glue on the glass plate, then place the glass plate in a vacuum oven and vacuumize. The temperature rise program is: the room temperature is raised to 100°C, and then the temperature is kept constant for 1h→100°C to 200°C. After constant temperature, the whole process is 1h→200°C and the temperature is raised to 300°C. The whole process of constant temperature is 1h→300°C, and the temperature is raised to 400°C. The infrared spectrogram of the polyimide composit...

Embodiment 2

[0040] At room temperature, under an argon atmosphere, 0.18g of montmorillonite (MMT) was sonicated in (73.1ml) N,N-dimethylformamide for 2h, and 5.4865g (0.01mol) of N 1 ,N 4 -bis(3'-amino-[1,1'-biphenyl]-4-yl)terephthalamide(NADPA) and 2.1812g(0.01mol)1,2,4,5-Benzenetetracarboxylic anhydride(1,2,4,5 -Pyromellitic dianhydride, PMDA) was added to N,N-dimethylformamide with a solid content of 30%, and stirred for 6 hours to obtain a homogeneous and viscous polyamic acid / montmorillonite composite glue. Scrape-coat the polyamic acid / montmorillonite composite glue on the glass plate, then place the glass plate in a vacuum oven, vacuumize, and the temperature rise program is: the room temperature is raised to 100°C, and then the temperature is kept constant throughout the process for 1h→100°C to After 200°C, keep the temperature for 1h→200°C to 300°C, keep the temperature for 1h→300°C to 400°C, then keep the temperature for 1h. After cooling, the polyimide / montmorillonite composit...

Embodiment 3

[0043] At room temperature, under an argon atmosphere, 0.03g graphene oxide (GO) was ultrasonicated in (46ml) N-methylpyrrolidone for 6h to obtain a graphene oxide dispersion. At the same time, 4.5856g (0.01mol) 4,4' -(((naphthalene-2,7-diylbis(oxy))-bis-(butane-4,1-diyl))-bis(oxy))dianiline(NOC 3 OPA) and 2.1812g (0.01mol) 1,2,4,5-Benzenetetracarboxylic anhydride (1,2,4,5-pyromellitic dianhydride, PMDA) were added to N-methylpyrrolidone with a solid content of 10 %, stirring and reacting for 6 hours to obtain a homogeneous and viscous polyamic acid glue, and then pour the graphene oxide dispersion into the polyamic acid glue to obtain a polyamic acid / graphene oxide composite glue. Scrape-coat the polyamic acid / graphene oxide composite glue on the glass plate, then place the glass plate in a vacuum oven, vacuumize, and the temperature rise program is: the room temperature is raised to 100°C and then the temperature is kept constant for 1h→100°C to After 200°C, the whole proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com