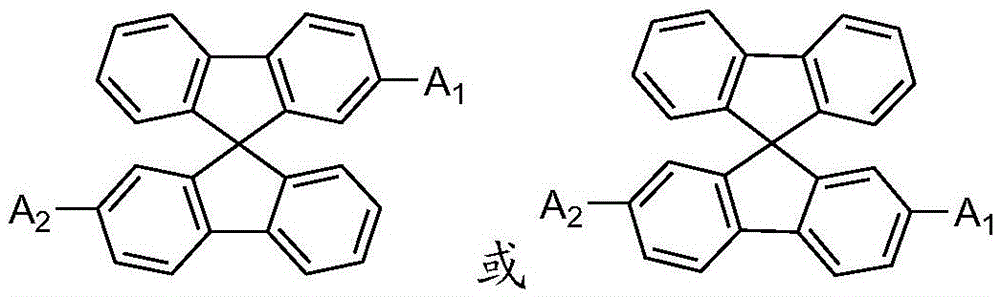

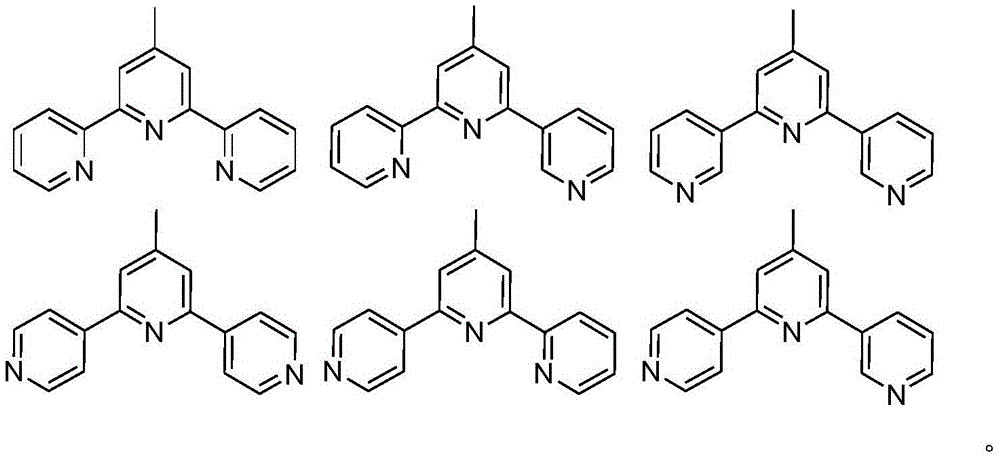

Electronic-transmission luminescent material and application thereof

A luminescent material, electron transport technology, applied in luminescent materials, circuits, electrical components, etc., can solve the problem that it is difficult to meet the requirements of high efficiency and high color purity of blue light materials, achieve good electron transport performance, avoid aggregation and mutual effect, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

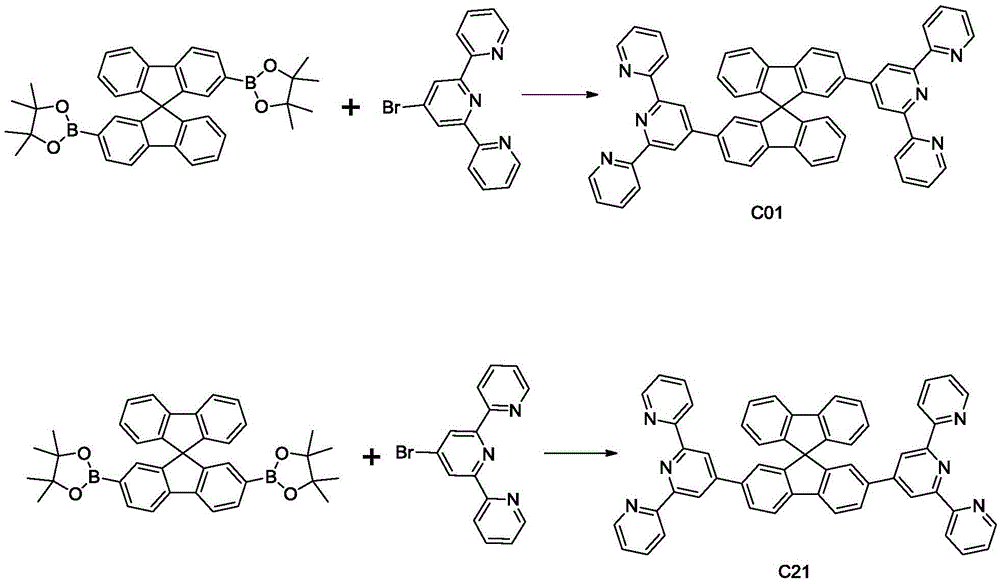

[0033] Embodiment 1 Preparation of electronic and luminescent material C01

[0034]

[0035] Under the protection of nitrogen, put in 2,2'-diboronate spirofluorene (1.137g, 2mmol), 4'-bromo-2,2':6',2"-tribromopyridine (1.374g, 4.4mmol ), an aqueous solution of potassium carbonate (80mL, 0.1mol / L), toluene (200mL), and finally the catalyst Pd (PPh 3 ) 4 (300mg, 0.26mmol), the system was heated to 90-100°C and kept for reaction for 36 hours. Add 50 mL of deionized water to stop the reaction. Collect the organic phase, get the crude product after dehydration, silica gel column chromatography, eluting agent uses V 乙酸乙酯 :V 正己烷 =1:20 purification and separation, a white solid was obtained, which was the crude product of the target compound C01.

[0036] The crude product was further sublimated and purified using a chemical vapor deposition system at a sublimation temperature of 320° C. to obtain compound C01 with a yield of 82%.

[0037] High resolution mass spectrometry, E...

Embodiment 2

[0039] Example 2 Preparation of electronic and luminescent material C21

[0040]

[0041] Under the protection of nitrogen, put in 2,7-diboronate spirofluorene (1.257g, 2.2mmol), 4'-bromo-2,2':6',2"-tribromopyridine (1.520g, 4.8mmol ), an aqueous solution of potassium carbonate (88mL, 0.1mol / L), toluene (200mL), and finally the catalyst Pd (PPh 3 ) 4 (300mg, 0.26mmol), the system was heated to 90-100°C and kept for reaction for 36 hours. Add 50 mL of deionized water to stop the reaction. Collect the organic phase, get the crude product after dehydration, silica gel column chromatography, eluting agent uses V 1,2-二氯乙烷 :V 正己烷 =1:25 Purification and separation to obtain a white solid, which is the crude product of the target compound C21.

[0042] The crude product was further purified by sublimation using a chemical vapor deposition system at a sublimation temperature of 315°C to obtain compound C21 with a yield of 86%.

[0043] High resolution mass spectrometry, ESI so...

Embodiment 3

[0047] Example 3 Application of Light Emitting and Electron Transport Material C01 in Organic Electroluminescent Devices

[0048] This embodiment prepares organic electroluminescence device according to the following method:

[0049] a) Clean ITO (indium tin oxide) conductive glass: use deionized water, acetone, and absolute ethanol to ultrasonically clean the ITO glass for 15 minutes each, and then treat it in a plasma cleaner for 2 minutes;

[0050] b) Vacuum evaporation or solution film-forming hole transport layer NPB on the anode ITO glass, with a thickness of 50nm;

[0051] c) On the hole transport layer NPB, a luminescent and electron transport layer C01 is vacuum evaporated, with a thickness of 60nm;

[0052] d) On top of C01, an electron injection layer LiF is vacuum-evaporated with a thickness of 1 nm;

[0053] e) On the electron injection layer LiF, a cathode Al is vacuum-evaporated to a thickness of 100 nm.

[0054] The optoelectronic data of device 1, such as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com