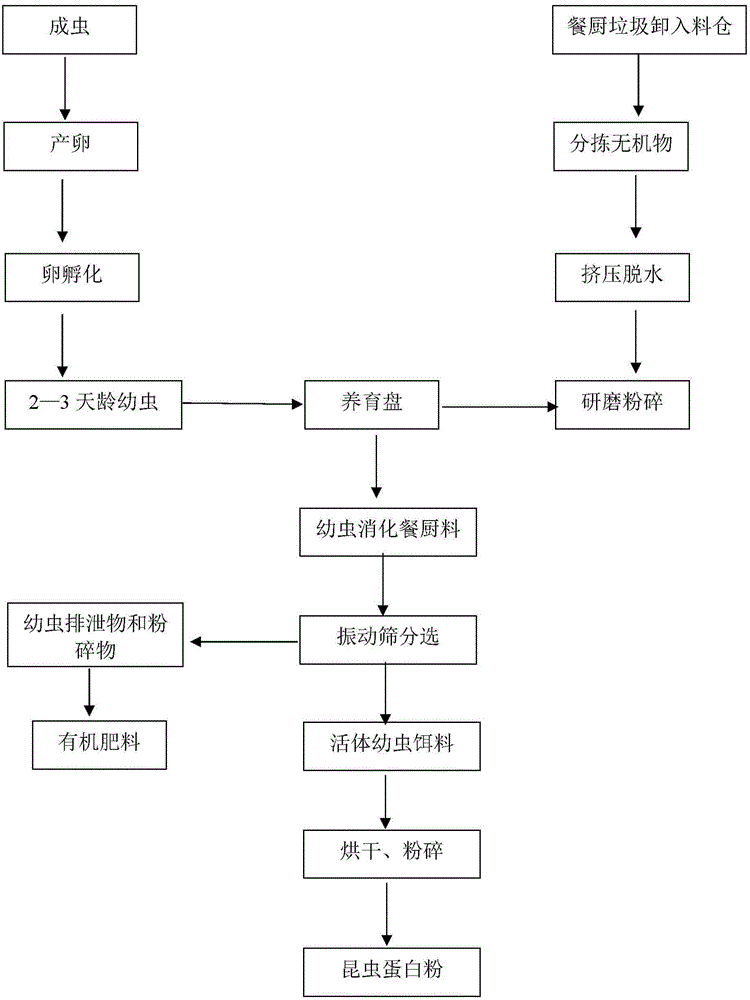

Biological treatment process of kitchen waste

A technology for the biological treatment of food waste, which is applied in the technical field of biological treatment of food waste, can solve the problems of poor practicability and increased treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 100 kg of kitchen waste, sorting out large pieces of inorganic materials. Extruded and dehydrated, the weight of the material after extrusion is 55 kg. Put the material into the culture tray and spray 100ml of lactic acid bacteria or yeast. Insert 30,000 2nd instar black soldier fly larvae into the rearing tray. The thickness of the nourishing material is 10cm. The rearing tray inoculated with black soldier fly larvae was placed in an environment with a temperature of 30°C and a humidity of 55% to raise the larvae. The larvae are raised for 6-8 days, and the rearing material has been basically digested to form pellets mainly composed of larval excrement. All the materials were moved to the sieve for screening, and 13.8 kg of larvae and 11 kg of organic fertilizer were isolated. The larva body was dried and pulverized to obtain 4.31 kg of insect protein powder.

Embodiment 2

[0018] 200 kg of kitchen waste, sorting out large pieces of inorganic materials. Extruded and dehydrated, the material weighs 125 kg after extrusion. Put the material into the culture tray and spray 300ml of lactic acid bacteria or yeast. Insert 80,000 2-instar Chrysocephala larvae into the rearing tray. The thickness of the nourishing material is 15cm. Place the culture tray inoculated with Chrysocephala larvae in an environment with a temperature of 33° C. and a humidity of 65% to raise the larvae. Chrysocephala larvae are raised for 6-8 days, and the rearing material has been basically digested to form granular material mainly composed of larval excrement. All materials are moved to the sieve for screening, and 19.5 kg of larvae and 27 kg of organic fertilizers are separated. The larva body was dried and pulverized to obtain 4.88 kg of insect protein powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com