Catalyst and method of reaction for preparing butanedioic anhydride from maleic anhydride through liquid phase hydrogenation

A technology for preparing succinic anhydride and catalyst, which is applied in chemical instruments and methods, molecular sieve catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of large loss rate of Pd, conversion rate of maleic anhydride and succinic anhydride selection. low Pd loss rate, excellent reactivity, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

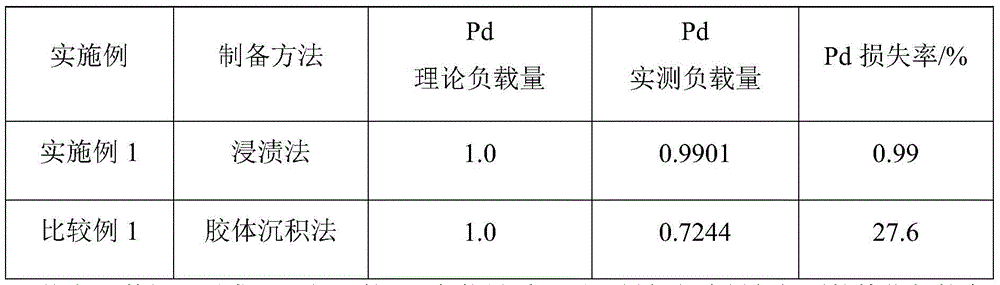

Problems solved by technology

Method used

Image

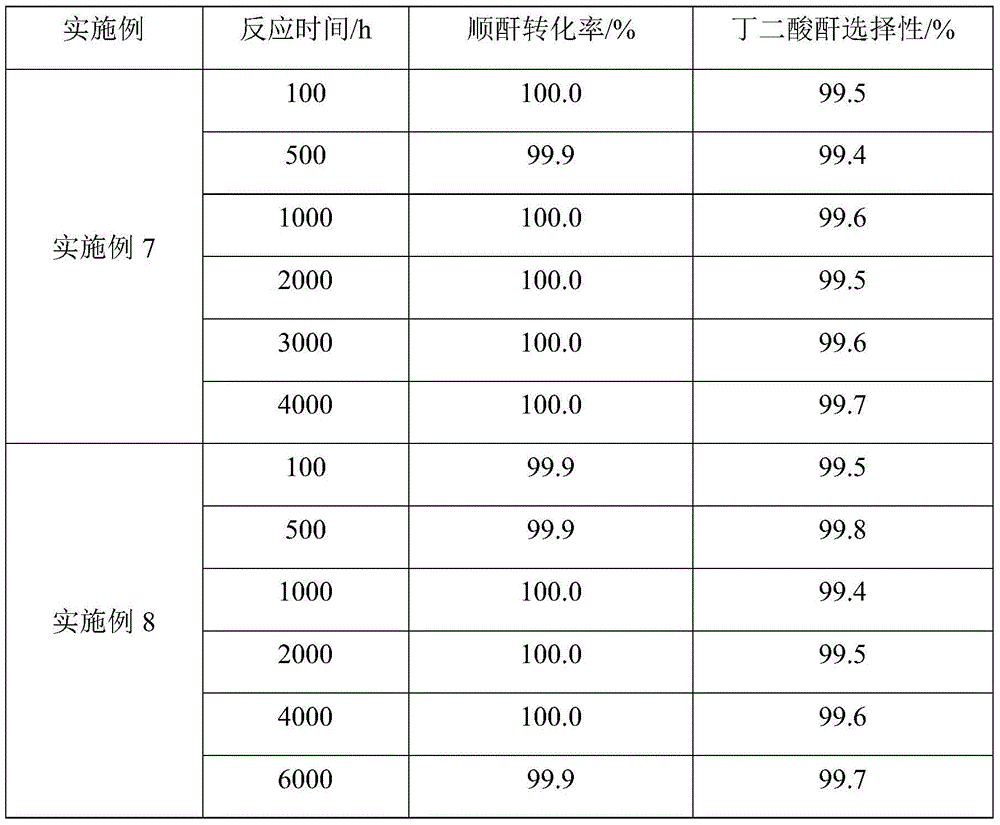

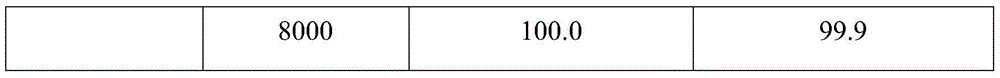

Examples

Embodiment 1

[0031] Weigh 500gSiO2 2 For the carrier, add 100g of silica sol and 300ml of aqueous solution to it and knead evenly in a kneader, place it in an extruder for extrusion molding, screen a circular template for extrusion, and cut into pellets with a pelletizer to obtain a long carrier. The formed carrier was dried at 110° C. for 24 hours, and then calcined at 600° C. for 8 hours to obtain a strip-shaped catalyst carrier.

[0032] A Pd-containing precursor impregnation solution was prepared, and the concentration of the impregnation solution was 0.01mol / L. Under normal pressure or vacuum, take 200 g of the formed strip-shaped carrier and immerse it in the impregnation solution. The impregnation temperature is 50°C, impregnated and stirred for 2 hours, dried at 110°C for 8 hours, and then calcined at 450°C for 4 hours. That is, a strip-shaped catalyst is obtained. The size of the bar-shaped catalyst is 2.0mm in particle size, 2-5mm in length, and 190m in specific surface area ...

Embodiment 2

[0041] Weigh 1000gSiO 2 Carrier, add 200g silica sol and 600ml aqueous solution to it, knead evenly in the kneader, put it in extruder to extrude, and screen the template to extrude and pelletize to obtain elongated carrier, and elongated particles are passed through The spherical granulator granulates into spherical granules. The formed carrier was dried at 110° C. for 24 hours, and then calcined at 600° C. for 8 hours to obtain a spherical catalyst carrier.

[0042] A Pd-containing precursor impregnation solution was prepared, and the concentration of the impregnation solution was 0.01mol / L. Under normal pressure or vacuum, take 200 g of the shaped spherical carrier and immerse it in the impregnation solution. The impregnation temperature is 50°C, impregnated and stirred for 2 hours, dried at 110°C for 8 hours, and then calcined at 450°C for 4 hours to obtain a spherical catalyst. The size of the spherical catalyst is 2.5mm in particle size and 200m in specific surface ar...

Embodiment 3

[0045] Weigh 800gSiO2 2 For the carrier, add 160g of silica sol and 480ml of aqueous solution, knead evenly in a kneader, put it in an extruder to extrude, screen a clover-shaped template, extrude, and cut into pellets to obtain a clover-shaped carrier. The formed carrier was dried at 110° C. for 24 hours, and then calcined at 600° C. for 8 hours to obtain a clover-shaped catalyst carrier.

[0046] A Pd-containing precursor impregnation solution was prepared, and the concentration of the impregnation solution was 0.01mol / L. Under normal pressure or vacuum, take 300 g of the formed clover carrier and immerse it in the immersion solution. The impregnation temperature is 50°C, impregnated and stirred for 2 hours, dried at 120°C for 8 hours, and then calcined at 550°C for 4 hours to obtain the clover-shaped catalyst. The size of the catalyst is 3.0mm in particle size and 220m in specific surface area 2 / g, pore volume 0.8ml / g, pore diameter 18nm. The lateral pressure strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com