Preparation method of high-purity instant fruit powder

A high-purity, fruit powder technology, applied in the field of food processing, can solve the problems of restricting the industrialization development of high-purity instant fruit powder, adding a large amount of auxiliary materials, and easily sticking to the wall, etc. drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Taking jujube as an example, a kind of preparation method of high-purity instant jujube powder, the steps are as follows:

[0040] 1) Weigh 10kg of jujube raw material, screen and clean it, add water 5 times the mass of jujube to cook, boil for 5 minutes, crush and beat, put it in a centrifuge for 5 minutes after beating, the speed of the centrifuge is 3000rpm / min; add fruit pulp Carry out enzymatic hydrolysis, the enzymatic hydrolysis temperature is 54°C, and the enzymatic hydrolysis time is 1.5h; the enzyme activity of the pulp enzyme is 50,000 U / mL. After enzymatic hydrolysis, the jujube pulp is filtered through a press-type filter with a mesh size of 50 mesh, and concentrated by low-temperature vacuum double-effect concentration. The concentration conditions are: the primary temperature is controlled at 65°C, and the secondary temperature is controlled at 55°C. The vacuum degree is controlled at 0.07MPa, and when the solid content reaches 30%, the material is discha...

Embodiment 2

[0051] Taking jujube as an example, a kind of preparation method of high-purity instant jujube powder, the steps are as follows:

[0052] 1) Weigh 40 kg of jujube raw materials, screen and clean them, add water 4 times the mass of jujubes to cook, boil for 5 minutes, crush and beat, put in a centrifuge after beating and centrifuge for 4 minutes, the speed of the centrifuge is 3000rpm / min; add fruit pulp Carry out enzymatic hydrolysis, the enzymatic hydrolysis temperature is 52°C, and the enzymatic hydrolysis time is 1.5h; the enzyme activity of the pulp enzyme is 40,000 U / mL. After enzymatic hydrolysis, the jujube pulp is filtered through a press-type filter with a mesh number of 50 mesh, and concentrated by low-temperature vacuum double-effect concentration. The concentration conditions are: the primary temperature is controlled at 68°C, and the secondary temperature is controlled at 55°C. The vacuum degree is controlled at 0.07MPa, and when the solid content reaches 35%, the...

experiment example

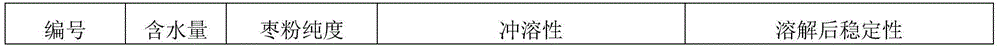

[0074] 1. Under the same conditions, carry out spray drying to prepare red date powder. The red date powder of the embodiment method of the present invention is blown by cold wind, transports the gained date powder and compares the date powder that comparative example 1-3 obtains, and the water content of red date powder, date The comparative results of powder purity and flushing solubility are shown in Table 1 below.

[0075] Table 1

[0076]

[0077]

[0078] 2. In the process of preparing jujube powder in the present invention, the dried fruit powder output by the spray drying tower is transported to the collection cylinder with clean air after dehumidification, and the temperature of the transported dehumidified air has obvious differences on the moisture content and product state of the product. By changing The temperature and water content of the clean air after dehumidification, and the comparison of the prepared red date powder are shown in Table 2:

[0079] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com