Multi-spindle caragana seed harvester

A multi-spindle, harvester technology, applied in the direction of pickers, harvesters, agricultural machinery and implements, etc., can solve the problems of cutting or tearing, spilling on sand, waste, etc., to improve harvesting efficiency, increase The effect of income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] see figure 1 In the shown multi-spindle caragana seed harvester, the outer periphery of the main shaft 1 that mainly transmits power has 3 protrusions that extend along the axis and look like flat keys; cooperate with it, such as Figure 5 (a) There are three grooves in the shape of keyways on the inner circle of the circular comb holder 2 of the collector shown in (a), the two cooperate to transmit torque, and the comb teeth 3 are fixed on the outer surface of the comb holder 2 . The comb holder 2 can slide along the axis direction along the surface of the main shaft 1, and the gap between the comb teeth 3 along the axis direction can be set by adjusting the washer. 6 collectors constitute a collector group, and there are 3 groups of such collector groups on each main shaft. The length of the comb teeth in each collector group increases sequentially from front to back, ranging from 300mm to 1000mm, and their combs The angles of the teeth in the circumferential direct...

Embodiment 2

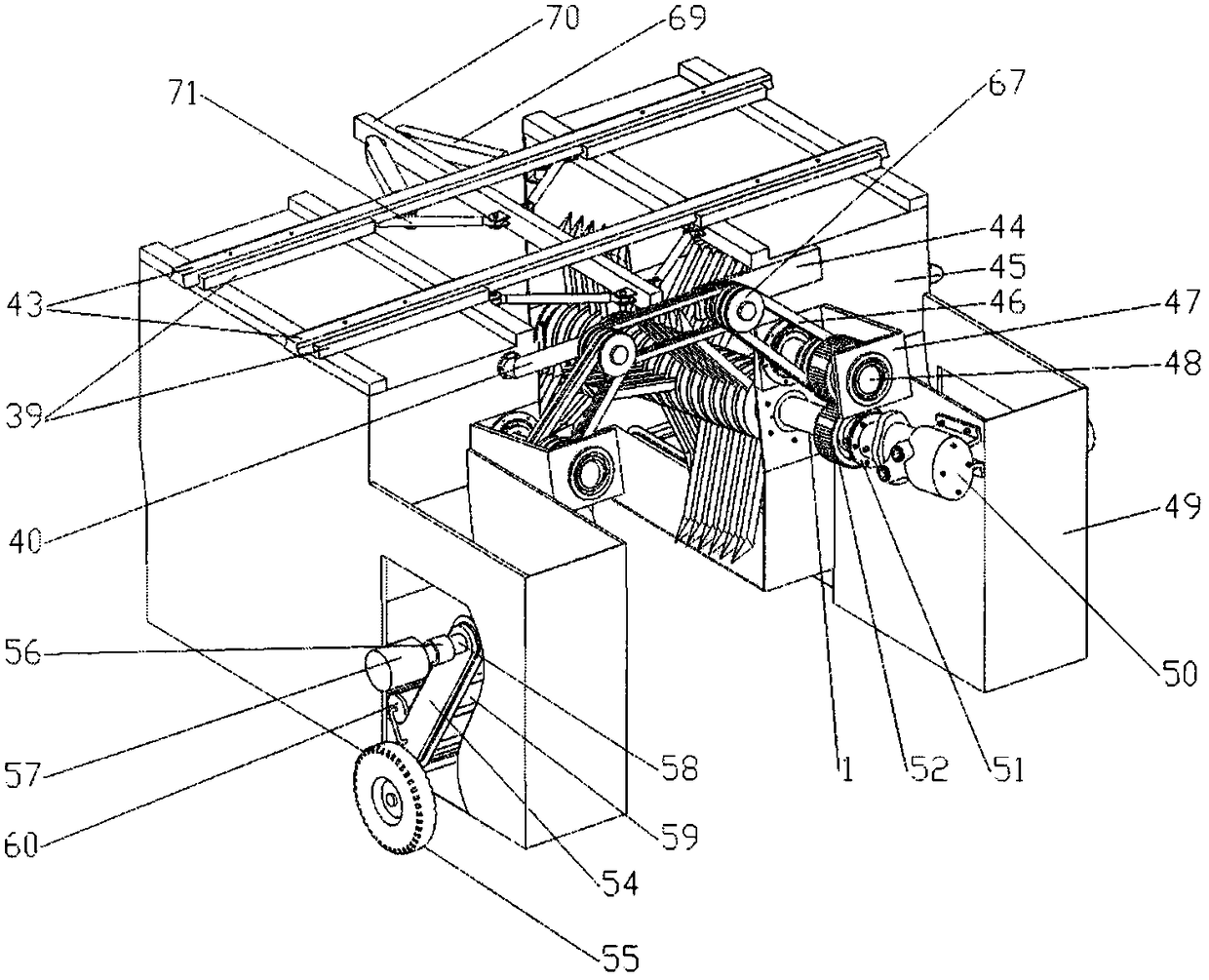

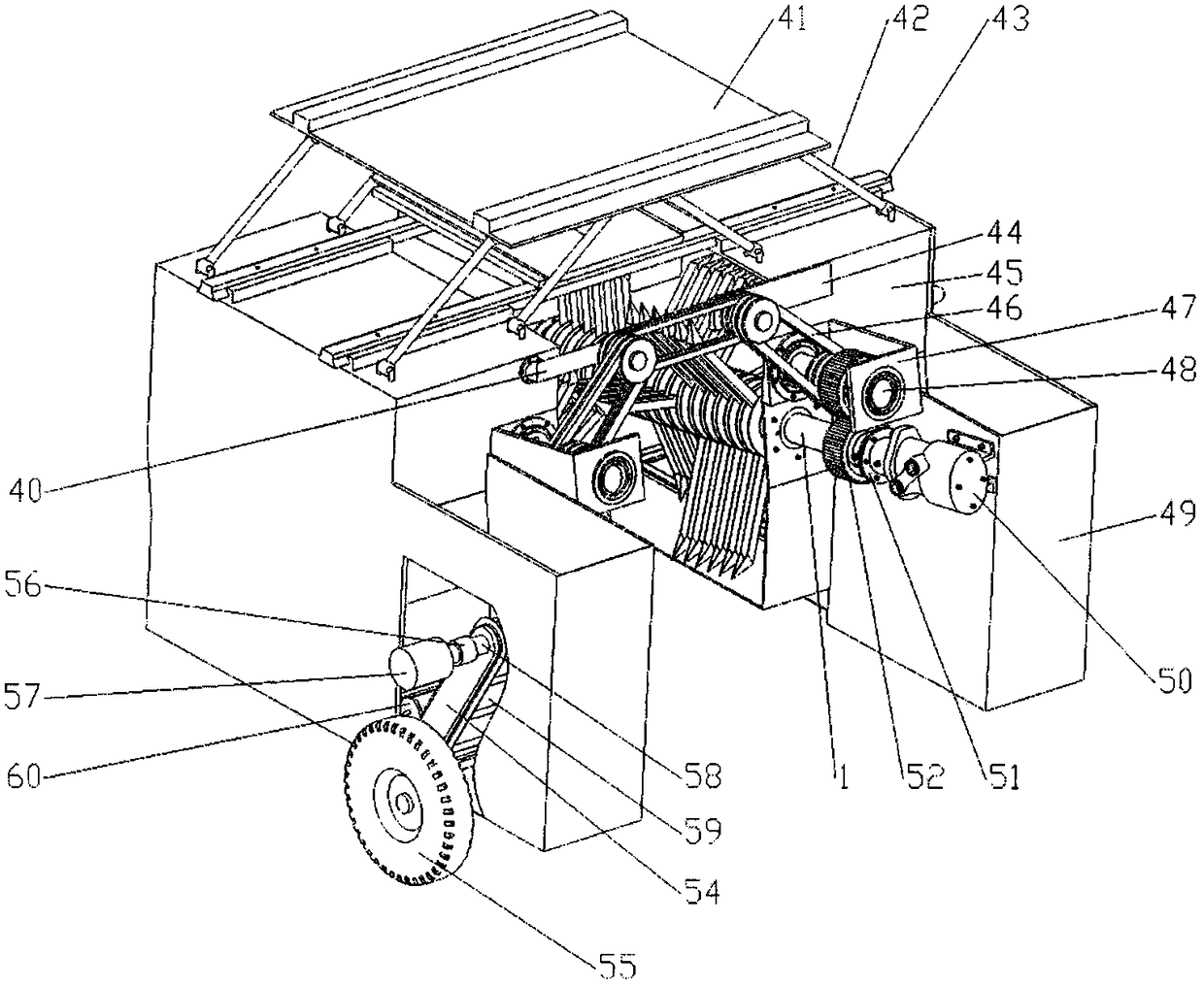

[0035] see Image 6 , a 4-spindle caragana seed harvester, the difference between embodiment 2 and embodiment 1 is: the number of spindles in embodiment 2 is 4, the left and right parts of the frame are two respectively, and the two parts on one side The two main shafts are arranged up and down, which are more suitable for the harvesting of the seeds of higher caragana japonica; the main shafts on the left and right sides have 2 motors 68 to provide power respectively, and the two main shafts on one side share the same one by belt 66 and pulley 67. The power of motor, like this, the meshing gear set that plays reversing effect in embodiment 1 has just saved, and also saved a group of belt and belt pulley in the middle; 64 forms, and the function of blower fan is that fruit pod and seed are sucked in the storage box 49; Two walking wheels 55 are set below the main shaft on the left and right sides. The above points are the main differences between Embodiment 2 and Embodiment 1...

Embodiment 3

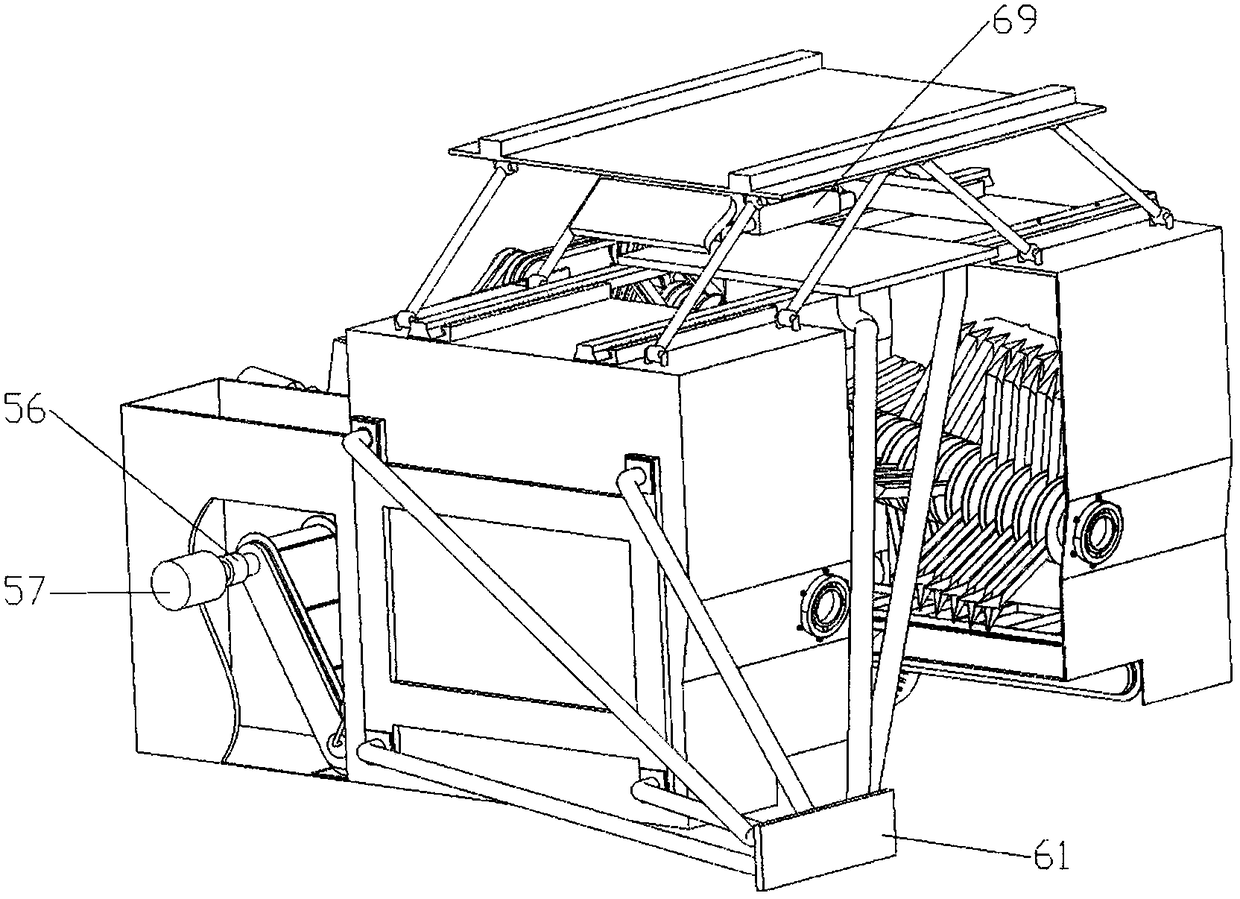

[0037] see Figure 8 , Figure 9 The difference between embodiment 3 and embodiment 1 and embodiment 2 is that the sliders fixed on the top of the left and right parts of the frame are widened and lengthened, and then become two whole steel plates 39, so that the left and right parts of the frame are formed into two parts. A whole with better rigidity, better stability and reliability, and a simpler structure, and the distance between the left and right acquisition units become a fixed value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com