Titanium-based multi-element thin film bicolor anode forming method and product thereof

A multi-element, thin-film technology, applied in ion implantation plating, superimposed layer plating, electrolytic coatings, etc., can solve problems such as practical operation difficulties, inability to produce gradient color changes, inability to provide metallic color and tactility, etc. To achieve a rich metallic luster effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

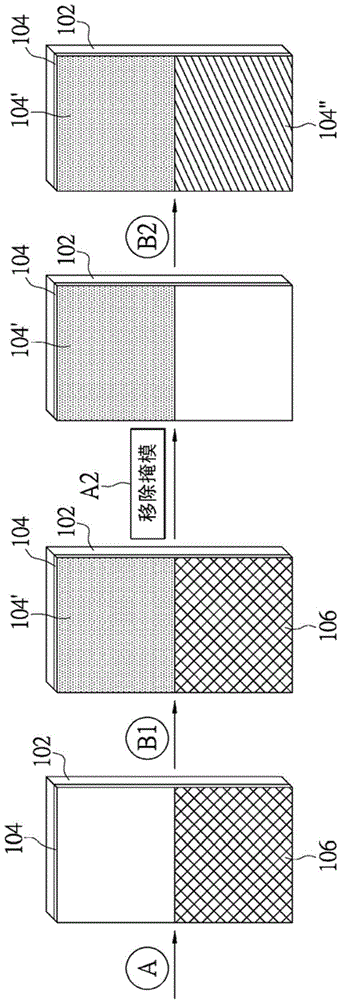

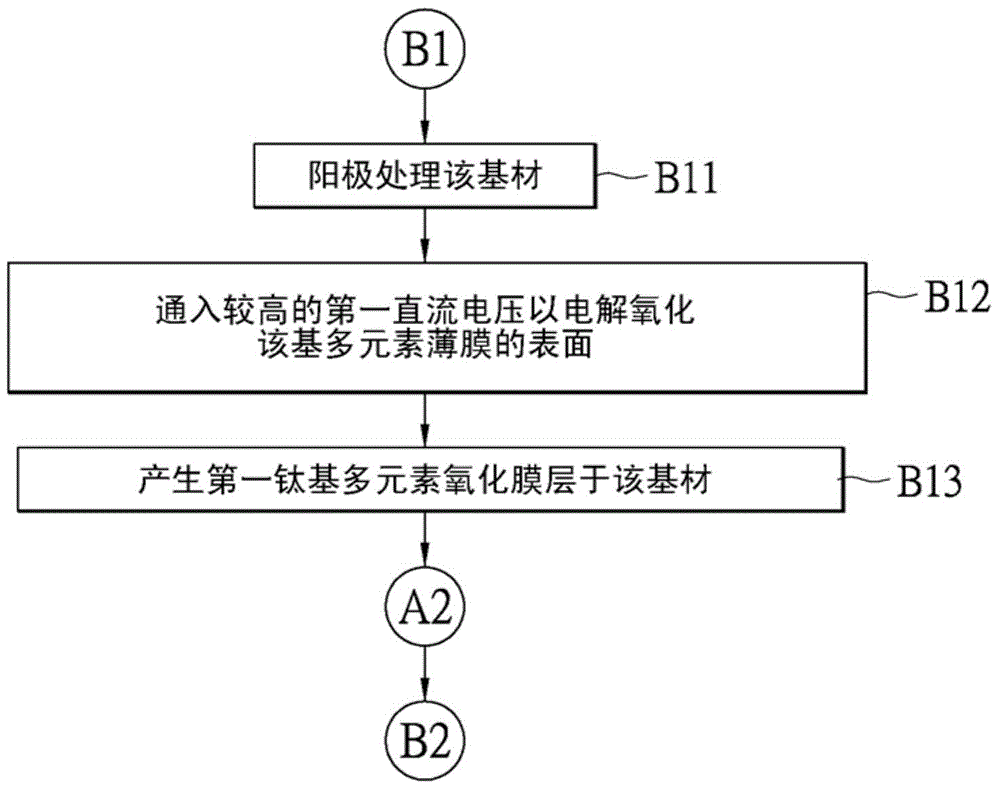

[0036] Please refer to figure 1 , is a schematic diagram of the method for forming a titanium-based multi-element thin film two-color anode of the present invention. The method for forming a titanium-based multi-element thin film two-color anode of the present invention can be divided into a preliminary process A, a first anodic oxidation process B1, a mask removal process A2, and a second anodic oxidation process B2. Each flow will be described below.

[0037] [Preparation Process A]

[0038] Please refer to figure 1 and figure 2 , figure 2 A schematic diagram of the steps of the preparatory process A of the present invention is shown. In step A11 , a base material 102 is provided. The base material 102 is mainly made of metal, which may be a metal shell, such as aluminum, aluminum alloy, stainless steel or magnesium alloy shell, or even a non-metal shell.

[0039] Next step A12, regarding the part of the metal casing, the base material 102 needs to be cleaned accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com