Method for producing heavy metal absorbent through microbiological treatment on lignite and related compound microbial agent

A technology of composite microbial agent and heavy metal, applied in the field of resource utilization of lignite, can solve few problems and achieve the effect of improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 fermented liquid

[0025] In this example, Beauveria bassiana was purchased from ATCC, numbered ATCC7159; Bacillus subtilis was purchased from ACCC, numbered ACCC19374; Candida tropicalis was purchased from ATCC, numbered ATCC20326.

[0026] (1) Activate the above-mentioned Beauveria bassiana (ATCC7159), Bacillus subtilis (ATCC11775), and Candida tropicalis (ATCC20326) into their respective slant media for preservation, and culture them at 26-37°C for 16-72 hours.

[0027] Preservation of three kinds of microorganisms uses the slant culture medium formula as follows:

[0028] The medium used for Beauveria bassiana: 200 grams of potato, 20 grams of glucose, 10 grams of peptone, 15 grams of agar, 1000 ml of tap water, natural pH;

[0029] Medium for Bacillus subtilis: 10 grams of peptone, 5 grams of glucose, 3 grams of beef extract, 5 grams of sodium chloride, 15 grams of agar, 1000 ml of tap water, pH7.2±0.2;

[0030] The medium used for...

Embodiment 2

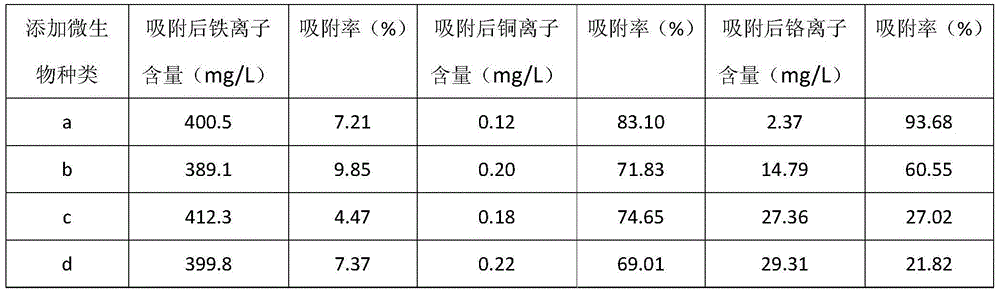

[0035] Example 2 Adsorption of copper-containing test solution after processing lignite with composite microbial bacterial agent

[0036] 1. Select 8kg of lignite coal powder (moisture content 20.0%) that has been crushed through a 80 mesh sieve, divide it into 4 parts on average, add in 4 20L reactors respectively, add 150g of soybean meal hydrolyzate (Shandong Yangcheng Biotechnology Co., Ltd.) and A total of 50g of urea, 100g of glucose, adding water to adjust the moisture content of the material to 90%, adjust the pH to 7.0, and the total volume is 16L;

[0037] 2, three kinds of microbial fermented liquids prepared in embodiment 1 are combined into composite microbial inoculum by following parts by weight: 20 parts by weight of Beauveria bassiana fermented liquid, 9 parts by weight of Bacillus subtilis fermented liquid, 8 parts by weight of Candida tropicalis fermented liquid parts by weight;

[0038] 3. Add 48ml each of the following microbial fermentation broth or micr...

Embodiment 3

[0044] Example 3 Adsorption of lead-containing test solution after processing lignite with composite microbial bacterial agent

[0045] 1. Select 12kg of lignite coal powder (moisture content 28.6%) that has been crushed through a 80-mesh sieve, divide it into 4 parts on average, add them to 4 20L reactors, then add 150g of peptone and 210g of glucose, and add water to adjust the moisture content of the material to 88%. , adjust the pH to 6.8, and the total volume is 17.9L;

[0046] 2. Prepare three kinds of microbial fermented liquids according to the method of Example 1, and mix uniformly by the following parts by weight to become composite microbial inoculum I: 19 parts by weight of Beauveria bassiana fermented liquid, 10 parts by weight of Bacillus subtilis fermented liquid, tropical pseudo 7 parts by weight of fermented liquid of Trichosomyces; mix uniformly according to the following parts by weight to form composite microbial agent II: 4 parts by weight of Beauveria bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com