Automatic deslagging system for dish-washing machine

A dishwashing machine, self-cleaning technology, applied in the direction of tableware washing machine/rinsing and washing machine parts, sustainable building, climate sustainability, etc., can solve the increase of dishwasher energy consumption, increase of dishwasher water consumption, pollution Tableware and other problems, to achieve the effect of reducing energy consumption and water consumption, improving the filtering effect, and shortening the slag cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

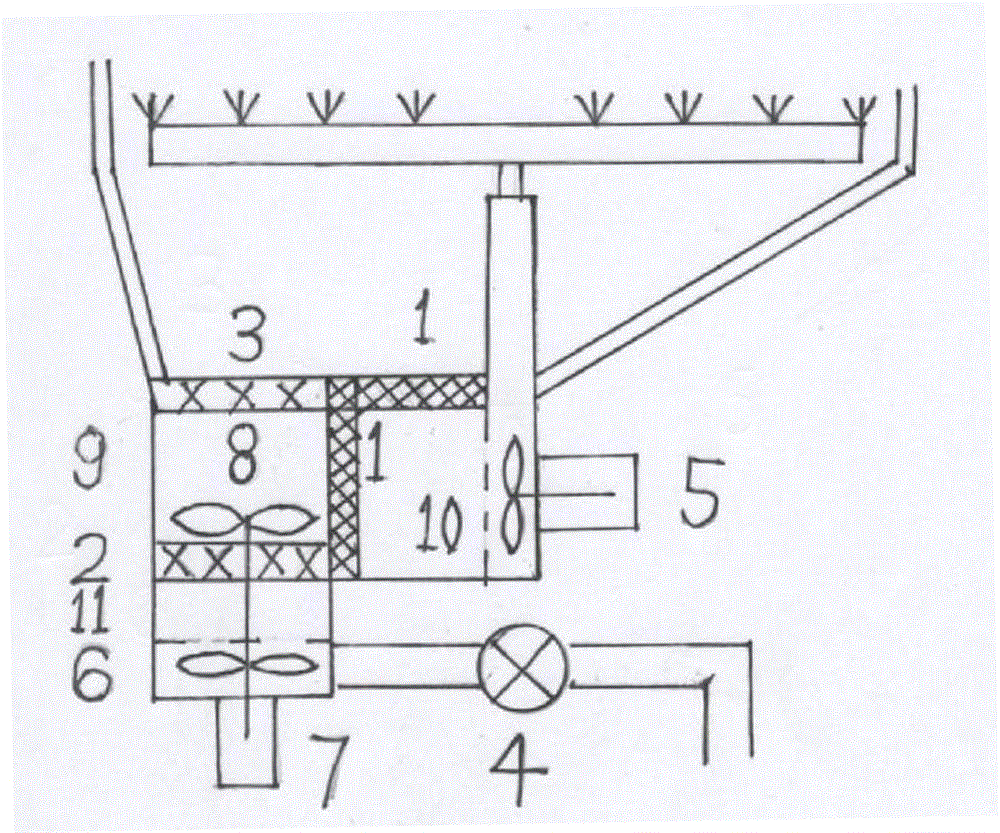

[0010] Embodiment: A self-cleaning slag removal system for a dishwasher, consisting of a washing filter 1, a drainage filter 2, a slag cutting filter 3, a washing pump 5, and a drainage pump 6 with a cutting blade 8, is characterized in that: The dishwasher is provided with a slag cutting chamber 9, a washing pump chamber 10 and a drainage pump chamber 11. The water inlet of the slag cutting chamber 9 is provided with a slag cutting filter 3, and the slag cutting chamber 9 communicates with the washing pump chamber 10 through the washing filter 1. The washing pump chamber 10 is provided with a washing pump 5, and the slag cutting chamber 9 is connected with the drainage pump chamber 11 through the drainage filter screen 2. Cutting blade 8, drainage pump chamber 11 is provided with drainage pump 6, the 6 water outlets of drainage pump are equipped with electric valve 4, the filter aperture of washing filter screen 1 is 1-2mm, the filter aperture of drain filter screen 2 is 3- -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com