Air-tight sealing device of head of belt conveyor

A belt conveyor and hermetic sealing technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem of affecting the working performance and service life of the device, improving the difficulty of equipment cleaning and maintenance costs, and the adverse effects of the working environment of the belt conveyor, etc. problems, to achieve the effect of improving the quality of equipment connection, reducing downtime for maintenance, and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

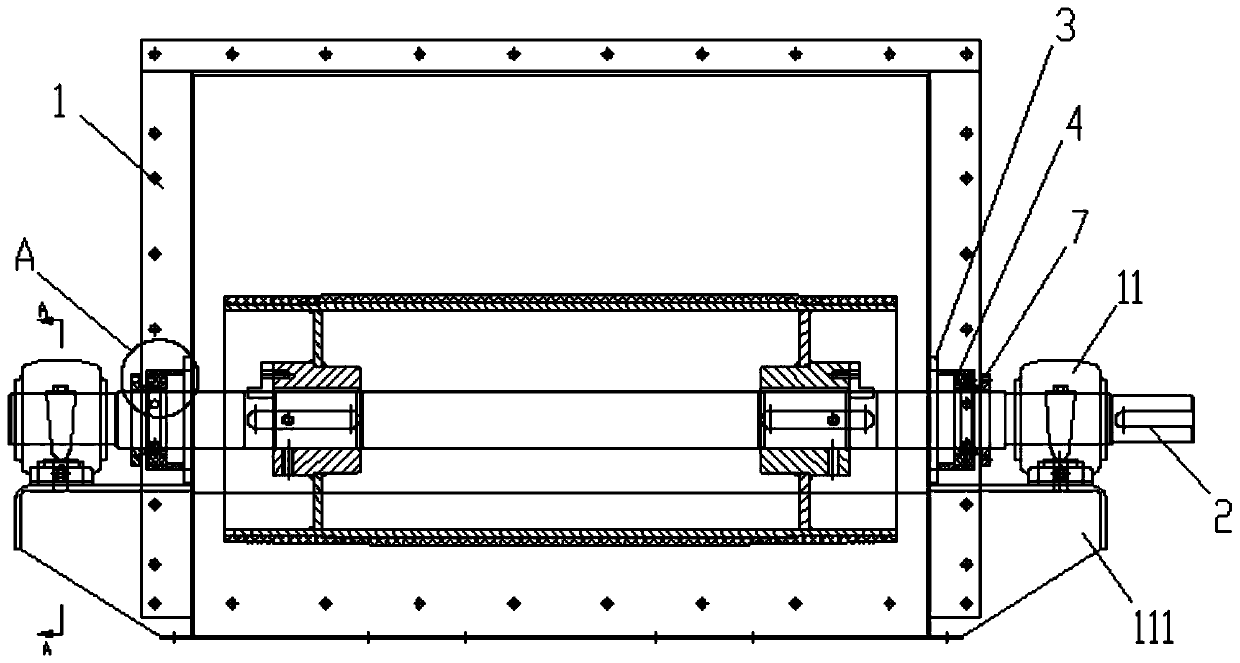

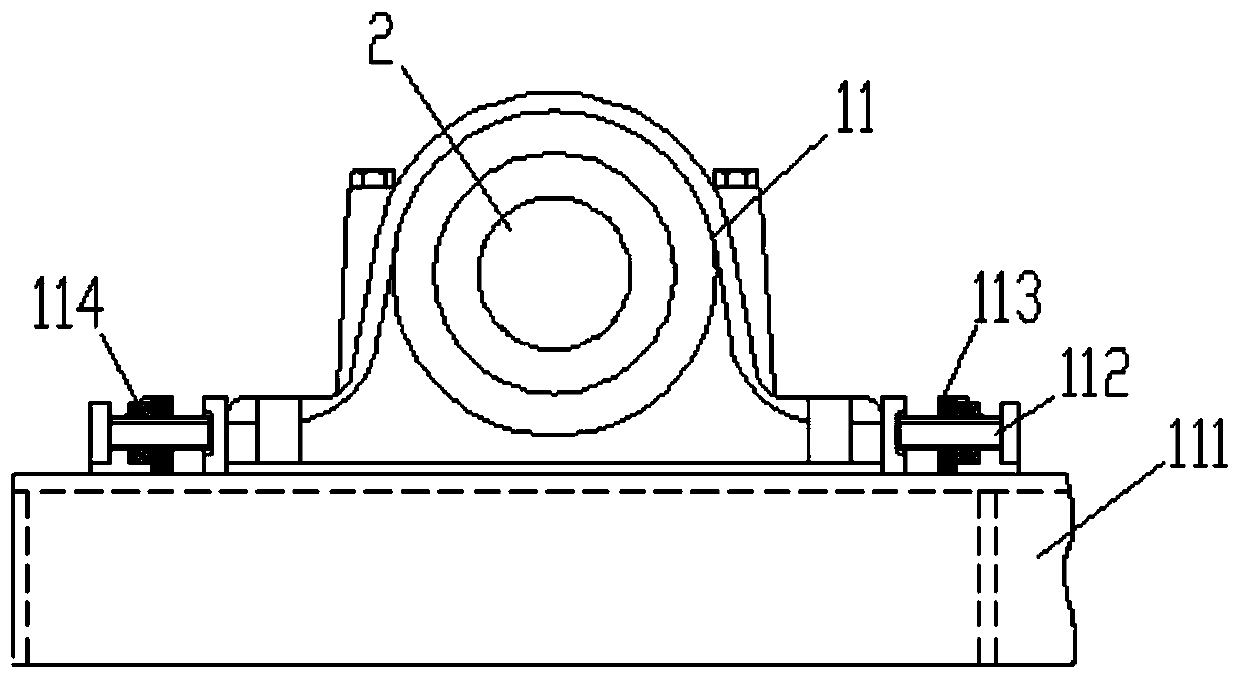

[0019] The structure of the head of the belt conveyor with the sealing device is as follows: figure 1 and 4 as shown, figure 2 and image 3 In order to highlight the structural features, some lines have been deleted. The two ends of the shaft 2 in the head housing 1 pass through the through hole of the housing and the sealing device in sequence, and are connected and positioned with the bearing seats 11 installed on both sides of the head housing 1. One end of the shaft 2 Used for connection with drive motors for rotary drive.

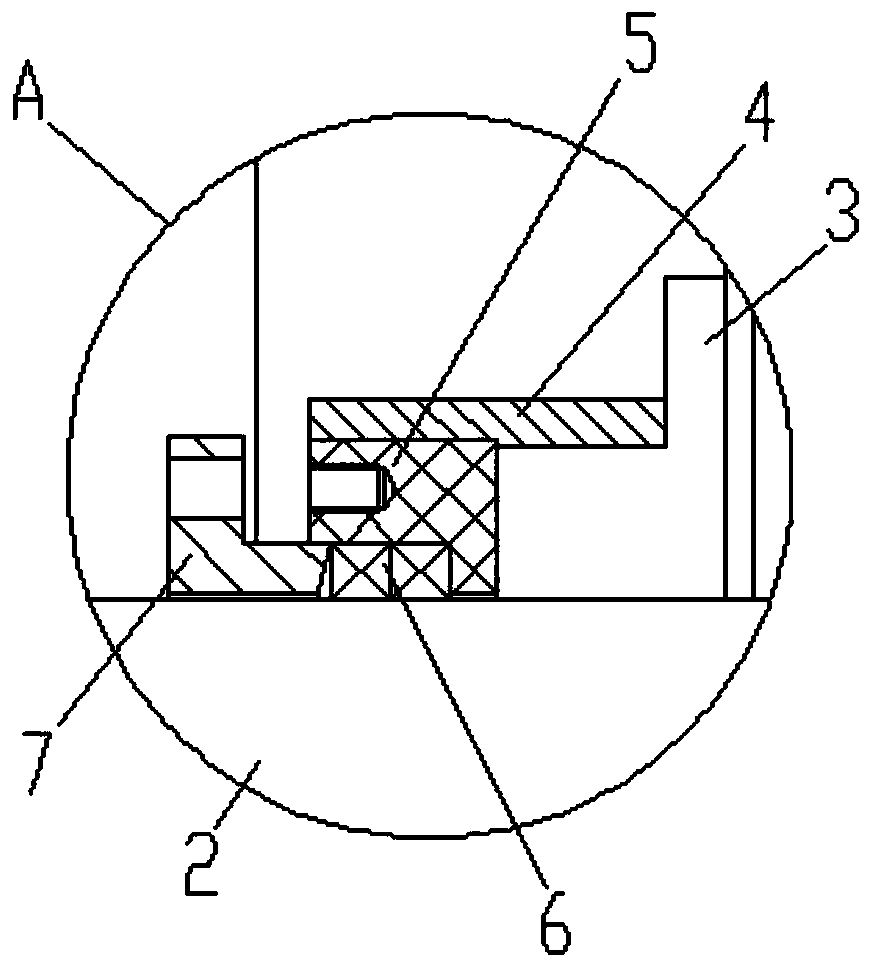

[0020] The structure of the sealing device is as follows figure 2 The figure includes a fixed plate 3 , a sealing plate 4 , a sealing gasket 5 and a sealing cover 7 arranged in sequence. The fixing plate 3 , the sealing tube 4 , the sealing gasket 5 and the sealing cover 7 are sequentially pierced to form an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com