System of premixing regenerated tobacco leaf production raw materials according to formula

A technology for reconstituted tobacco leaves and formulations, which is applied in the field of raw material formulation premixing systems for the production of reconstituted tobacco leaves, which can solve the problems of reduced equipment use efficiency, economic loss, and small processing capacity, so as to improve uniformity and stability, avoid large measurement errors, Taking into account the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

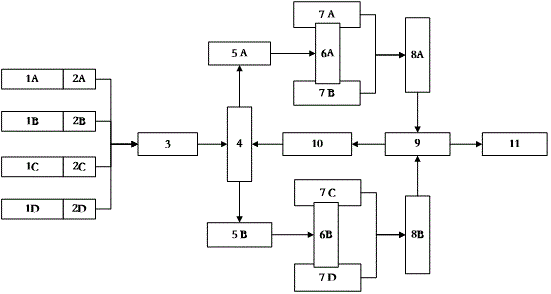

[0015] like figure 1 Show, a reciprocating foggy -producing raw material formula premix system, including: material storage conveyor 1. Measurement 2, first -class belt transport aircraft 3. Both directional belt transport aircraft 4. Two -level belt transport aircraft 5A and 5B, horizontal mobile fabric 6A 6A6B, the first set of formula warehouse 7A and 7B, the second set of formula 7C and 7D, the third -level belt transport aircraft 8A and 8B, the material 9, the fourth -class belt transport aircraft 10 and the fifth -level belt transport aircraft 11;1 The discharge of meter 2, measuring device 2 and first -class belt transport aircraft 3 are installed. First -level belt transport aircraft 3 connects with two -level belt transport aircraft 5A and 5B, and secondary belt transport aircraft 5A and 5B separate separately separately.Connect with the horizontal mobile fabric 6A and 6B, the horizontal mobile fabric 6A and 6B are installed on the first set of formulas 7A and 7B, the sec...

Embodiment 2

[0021] Repeat the embodiment 1, but there are different differences: the cigarette stalks used for reconstruction of tobacco leaves are used for recipe.

Embodiment 3

[0023] Repeat the embodiment 1, but there are different differences: the cigarettes used to make the cigarette production of tobacco leaf production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com