Novel-cable intermediate-joint explosion-proof apparatus

A technology of cable intermediate joints and explosion-proof devices, which is applied in the direction of cable joints, cable installation, and cable accessories. It can solve problems such as cable burnout safety, cable intermediate joint failures, and hidden dangers. The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

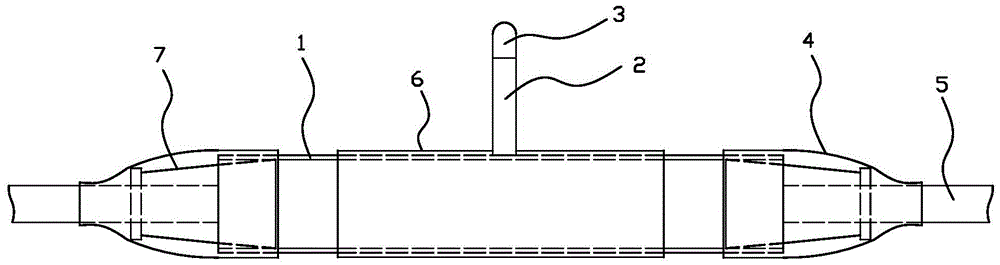

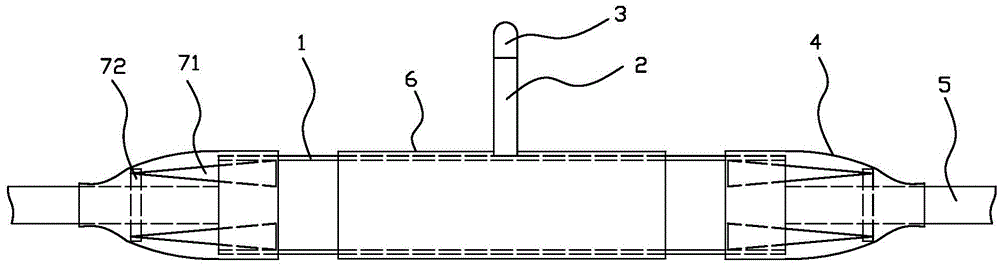

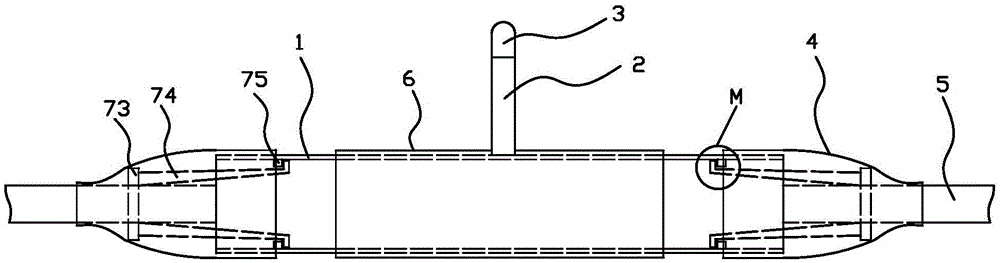

[0029] The present invention as Figure 1-7 As shown, it includes a protection tube 1, an explosion-proof tube 2, a heat-shrinkable sealing cap 3, a pair of reinforcement components 7 and a pair of heat-shrinkable sheaths 4, and the explosion-proof tube 2 communicates with the protection tube 1 and is arranged at the center of the protection tube 1 , the heat-shrinkable sealing cap 3 is sleeved on the mouth of the explosion-proof tube 2,

[0030] A pair of reinforcement components 7 are arranged symmetrically and are located at both ends of the protection tube 1, and the reinforcement components are connected between the cable 5 and the protection tube 1;

[0031] A pair of heat-shrinkable sheaths 4 are respectively provided at the nozzles at both ends of the protective tube, and the heat-shrinkable sheaths 4 are sheathed on the protective tube 1 , the reinforcing component 7 and the cable 5 in sequence.

[0032] During work, the cable 5 is passed through the protective tube....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com