An oil immersion treatment device for single point mooring system power transmission

A technology of single-point mooring and oil immersion treatment, which is applied in the direction of switchgear, electrical components, filtration and separation, etc., can solve the hidden dangers of equipment safety, reduce the high-voltage resistance and breakdown resistance of equipment, and have no unified plan to achieve guaranteed Reliable and stable work, guaranteed reliability, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

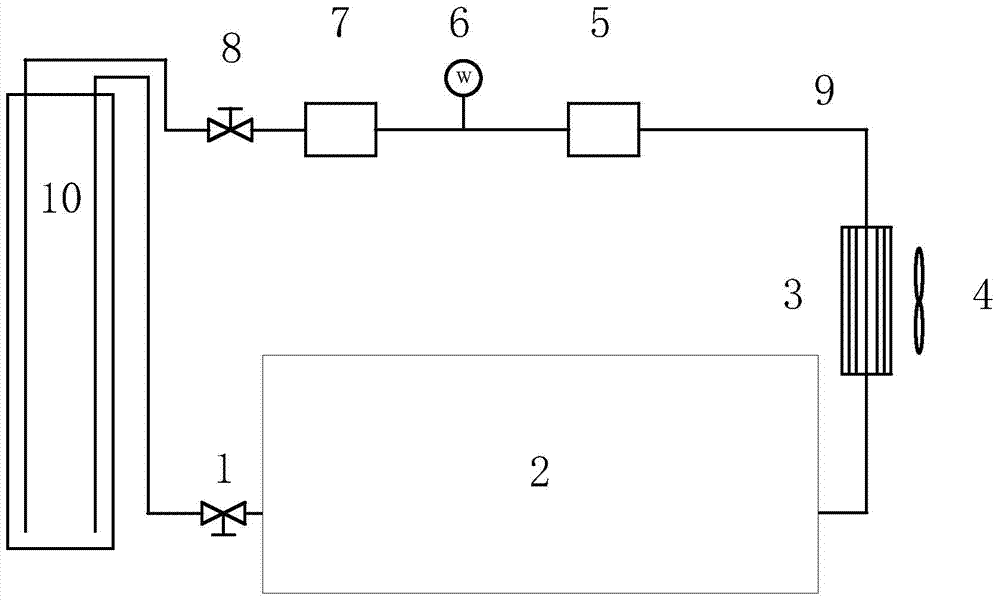

[0028] Such as figure 1 As shown, an oil immersion treatment device for single point mooring system power transmission, which includes: oil inlet valve 1, online monitoring equipment 2, water removal filter 3, self-cooling radiator 4, particle removal high-efficiency filter 5. Motor 6, oil pump 7, oil outlet valve 8, oil chamber 10 and pipeline 9. The peripheral equipment is power generation system and single point mooring system.

[0029] The power generation system is located at the bottom of the oil chamber 10, and the top of the oil chamber 10 is higher than the sea level. The high voltage line of the power generation system passes through the oil chamber 10 to supply power for the single point mooring system.

[0030] Both ends of the pipeline 9 are located in the oil chamber 10, and the pipeline 9 is provided with an oil inlet valve 1, an online mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com