Method of forming semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as gate germanium and silicon residues, and achieve the effect of reducing the formation of gate germanium and silicon residual defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It can be seen from the background art that in the prior art, after the embedded silicon germanium source and drain are formed, silicon germanium remains in the gate.

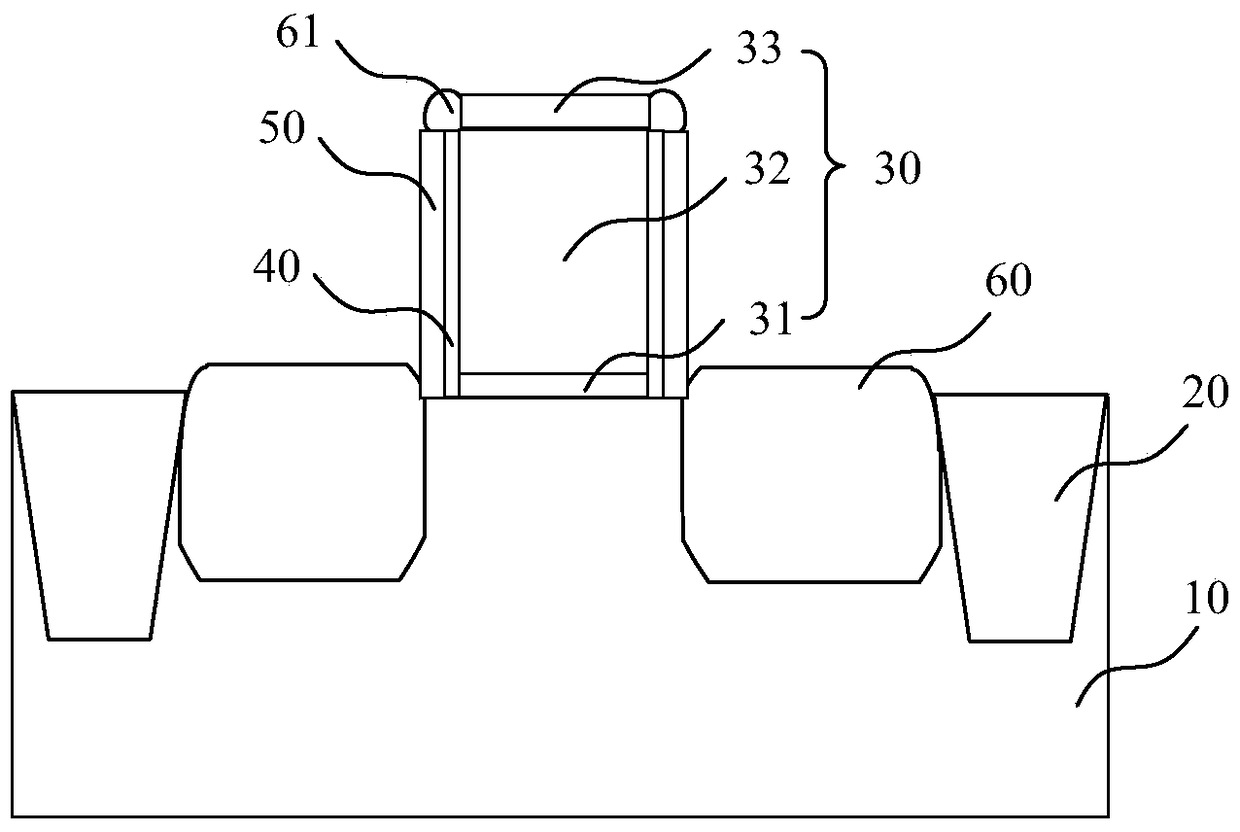

[0021] The inventors of the present invention have studied the formation method of the embedded silicon germanium source and drain of the prior art and found that, with reference to figure 1 In the prior art, after the gate structure 30 is formed on the semiconductor substrate 10, the sidewall of the polysilicon gate electrode layer 32 will be oxidized to form an oxide layer 40, and then a nitride layer covering the surface of the semiconductor substrate 10 and the gate structure 30 will be formed. silicon layer, etching the silicon nitride layer to form sidewalls 50 . However, during the formation of the silicon nitride material, less silicon nitride is formed at the shoulder of the gate electrode layer 32 at the junction of the hard mask layer 33 and the oxide layer 40 . In the subsequent epitaxial gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com