Method of directly preparing flexible and transparent conductive film through sol-gel process

A transparent conductive film, gel method technology, applied in circuits, electrical components, heat treatment equipment, etc., can solve the problems of inability to form films, small film grain size, high resistivity, etc., to optimize electrical conductivity, slow down The effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of Al-ZnO sol with an Al doping atomic ratio of 1%: the zinc source is zinc acetate, the doping source is aluminum nitrate, the solvent is ethylene glycol methyl ether, and the stabilizer is ethanolamine. The molar ratio of aluminum nitrate to zinc acetate is 1:99, the molar ratio of ethanolamine to metal atoms is 1:1, and the sol concentration is 0.75mol / L. The raw materials zinc acetate and aluminum nitrate are weighed according to the ratio and dissolved in the solvent Add stabilizer ethanolamine to ethylene glycol methyl ether, and stir the mixed solution in a water bath at 60°C for 1 hour to obtain a transparent and clear liquid. After constant volume, continue to stir for 2 hours, and finally age at room temperature for 24 hours to obtain a stable and transparent Al - Sol of ZnO;

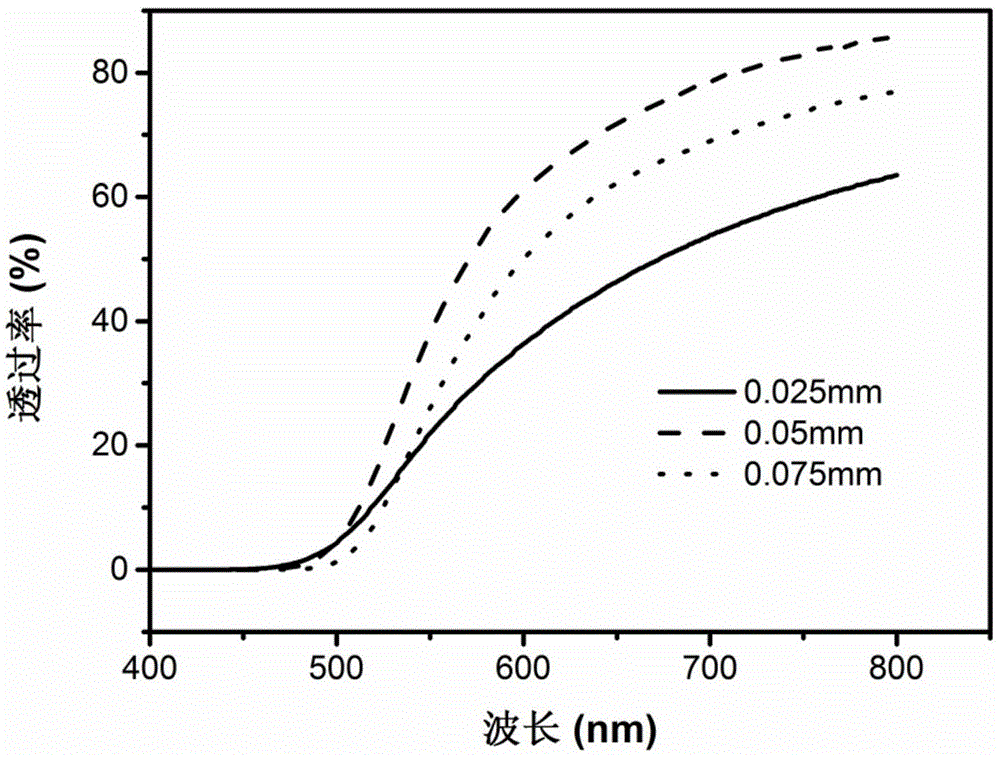

[0040](2) Cleaning of polyimide flexible substrates: the polyimide flexible substrates with thicknesses of 0.025mm, 0.050mm and 0.075mm were washed with dilute hydrochlo...

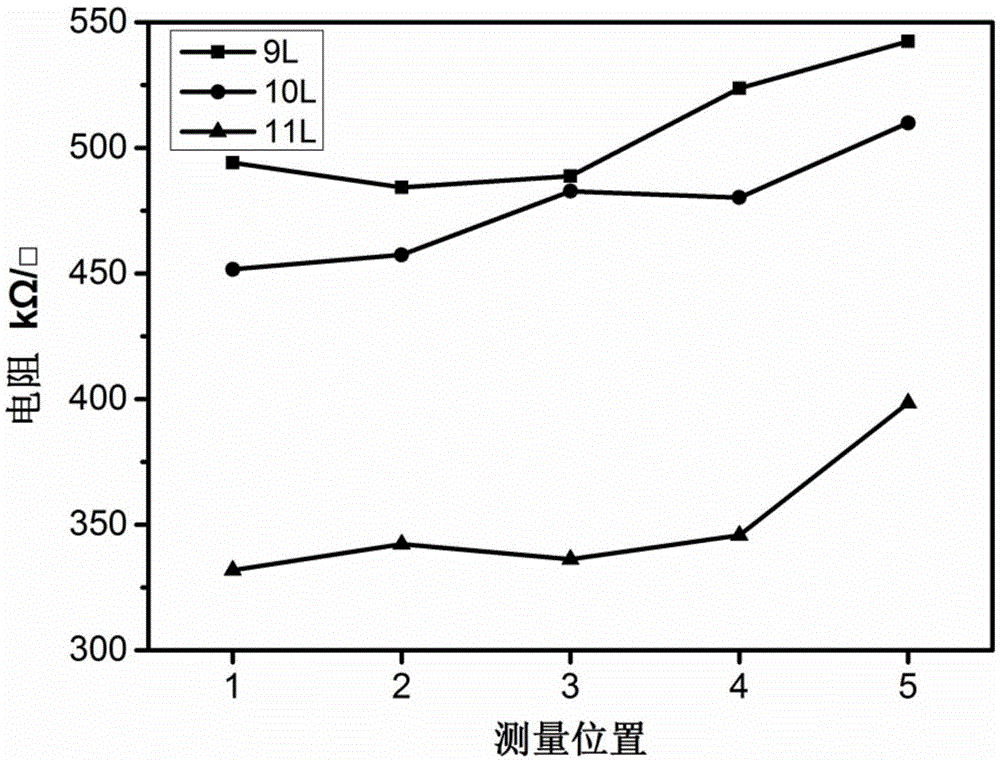

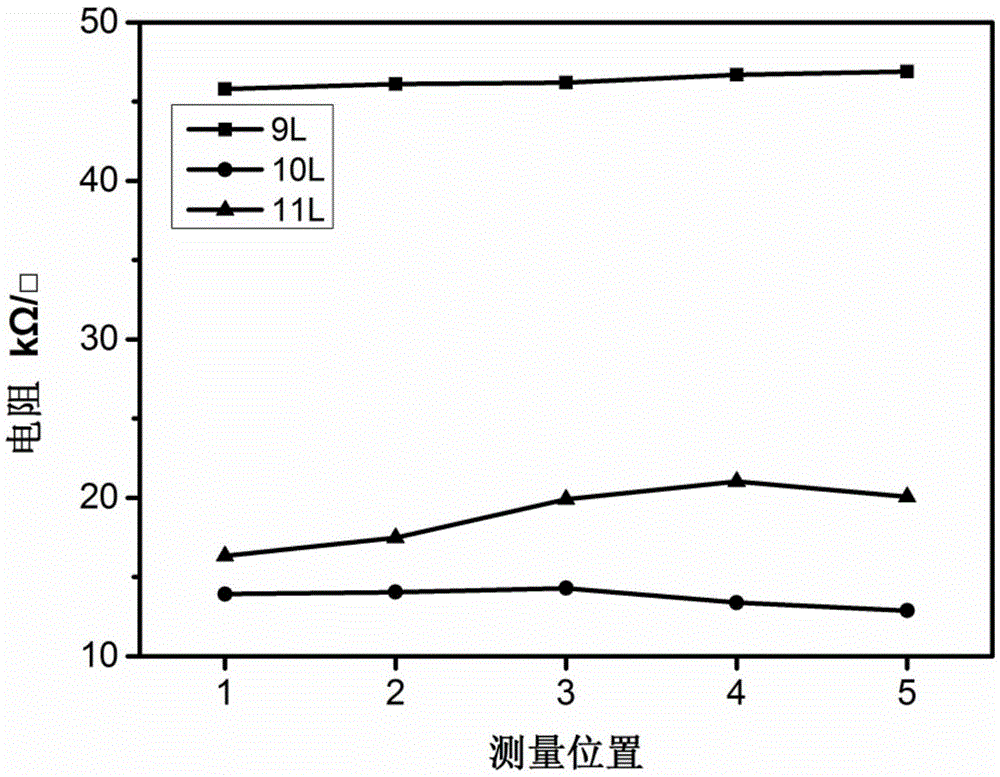

Embodiment 2

[0050] (1) Preparation of Al-ZnO sol with an Al doping atomic ratio of 1%: the zinc source is zinc acetate, the doping source is aluminum nitrate, the solvent is ethylene glycol methyl ether, and the stabilizer is ethanolamine. The molar ratio of aluminum nitrate to zinc acetate is 1:99, the molar ratio of ethanolamine to metal atoms is 1:1, and the sol concentration is 0.75mol / L. Weigh the raw materials zinc acetate and aluminum nitrate according to the ratio, dissolve them in the solvent ethylene glycol methyl ether, add the stabilizer ethanolamine, stir the mixed solution in a water bath at 60°C for 1 hour to obtain a transparent and clear liquid, and then Continue to stir for 2h, and finally age at room temperature for 24h to obtain a stable and transparent Al-ZnO sol;

[0051] (2) Cleaning of the polyimide flexible substrate: the polyimide flexible substrate with a thickness of 0.075mm is sequentially washed with 10% dilute hydrochloric acid, deionized water, and 10% sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com