Bionic cable

A technology for cables and oil pipes, applied to cables. It can solve the problem that the insulating oil cannot flow down the oil pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

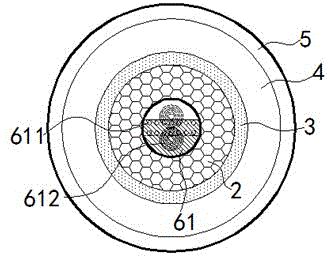

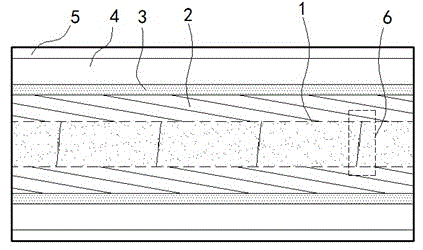

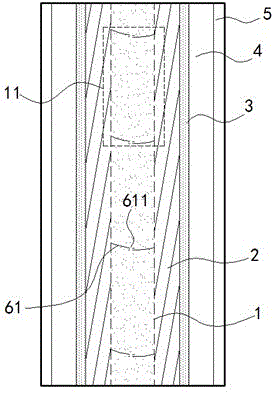

[0015] exist Figure 1 to Figure 3 In the shown embodiment, the bionic cable includes an oil pipe 1, a wire layer 2, a shielding layer 3, an insulating layer 4 and a housing 5 from the inside to the outside, and the oil pipe 1 communicates with the supplementary oil tank; and supplementary oil tank is filled with insulating oil; the oil pipe 1 is made of insulating material, and a diversion hole is opened on the pipe wall of the oil pipe 1; an isolator is installed equidistantly in the axial direction inside the oil pipe 1 6, such as figure 2 Shown in the dotted line box in the middle; each said cut-off device 6 divides said oil pipe 1 into oil sections 11 of equal length, as image 3 Shown in the dotted line box in the middle; the partition 6 includes a pair of shrapnel 61 parallel to each other, stacked and perpendicular to the axis of the oil pipe 1, and the length of the shrapnel 61 is 0.6-0.8 times the diameter of the oil pipe 1; the shrapnel 61 The fixed end is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com