Manufacturing method of large-area total focusing type double curvature bent crystals

A technology of curved crystals and manufacturing methods, which is applied in the field of large-area full-focus double-curvature curved crystals. It can solve the problems of forced cooling and maintenance of instruments, focus point astigmatism, waste of electric energy, etc., and achieve the improvement of diffraction efficiency and the miniaturization of instruments. , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

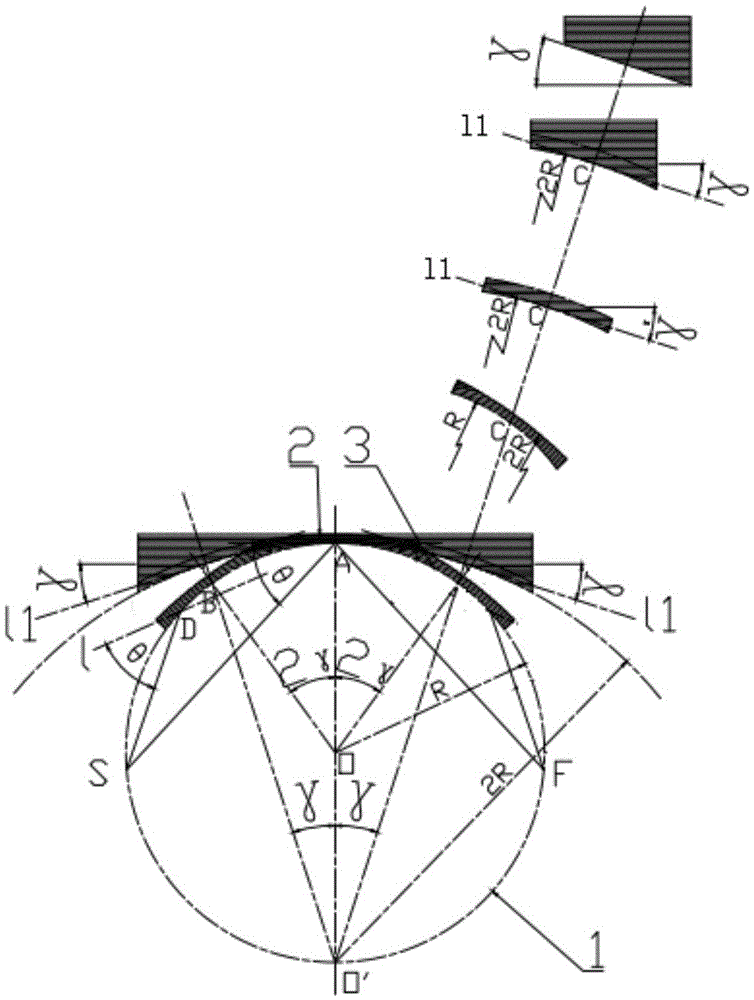

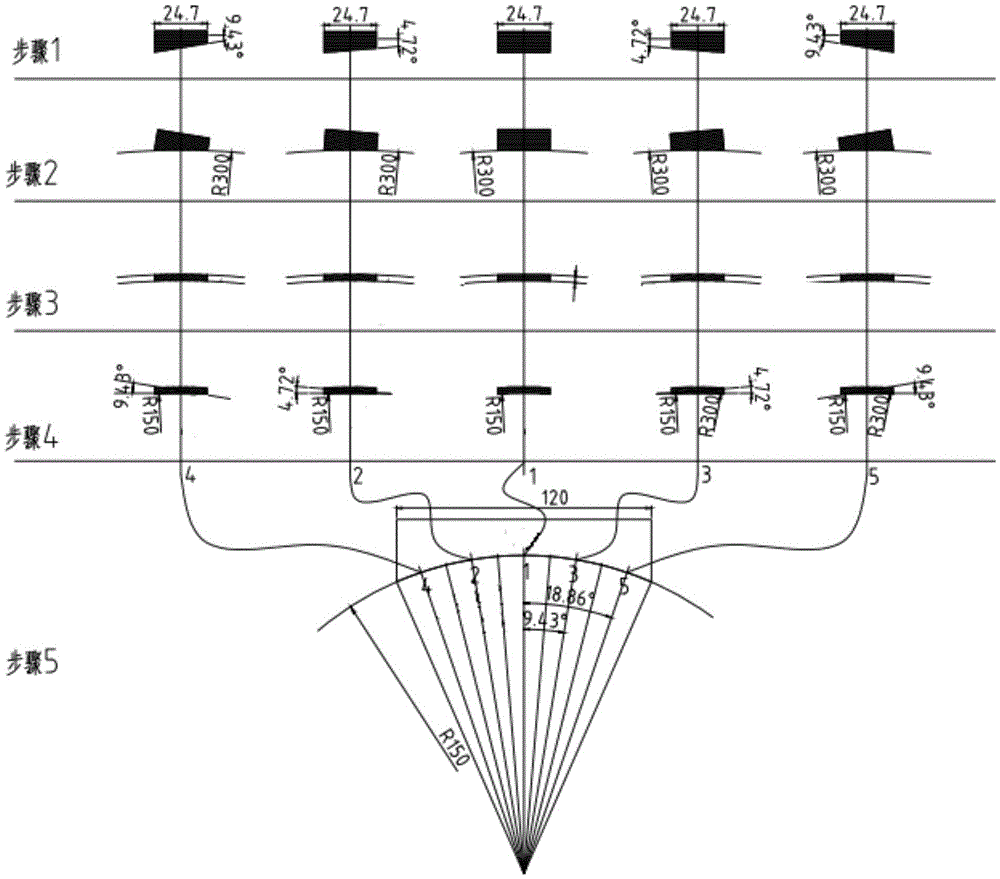

[0043] Embodiment: a kind of manufacturing method of large-area all-focus type double-curvature curved crystal is characterized in that it comprises the following steps:

[0044] 1. Rowland circle direction: if Figure 4

[0045] (1) Processing center wafer 2:

[0046] In the first step, the surface of the crystal blank is ground to be parallel to the crystal plane; in the second step, a 2R concave arc surface is ground on the crystal surface, and the center of the arc surface is point A; in the third step, along the direction parallel to the 2R surface, remove the Crystal slice; the fourth step is to align the center point A of the crystal slice with the position corresponding to the center point A on the Rowland circle of the wafer, continue to bend the crystal slice, and finally bend the radius of curvature of the inner surface of the crystal slice to R;

[0047] (2) Processing wafers 3 on both sides of the central wafer:

[0048] In the first step, according to the size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com