Novel ozone aging machine for plastics

An ozone aging and aging machine technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as air pollution and environmental damage, and achieve the effects of saving resources, being easy to move, and avoiding air pollution by ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

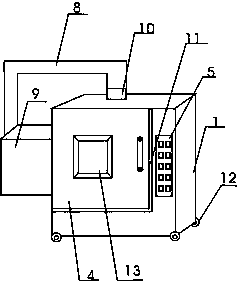

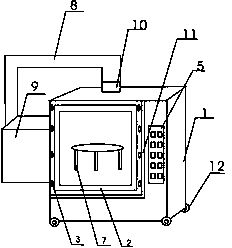

[0011] The invention provides a new type of ozone aging machine for plastics, which includes an aging machine body 1, an insulation layer 2, a heater 3, a cabinet door 4, a controller 5, an ozone generator 6, a sample rack 7, a recovery pipe 8, and an ozone recovery box 9. Exhaust fan 10, sealing strip 11, movable wheel 12, observation window 13, sample rack 7 is a rotating sample rack 7, cabinet door 4 and controller 5 are installed on the outside of aging machine body 1, and movable Wheel 12, an exhaust fan 10 is installed on the upper side of the aging machine body 1, and a recovery pipe 8 is installed on the upper side of the exhaust fan 10, and the other side of the recovery pipe 8 is connected to the ozone recovery box 9. 1 is provided with an insulation layer 2 inside, a heater 3 is installed between the insulation layer 2 and the aging machine body 1, an observation window 13 is opened on the cabinet door 4, and a sealing strip 11 is installed on the cabinet door 4 and ...

Embodiment 2

[0013] During use, the product that needs to be detected is put into the rotating sample rack 7, then the cabinet door 4 is closed, the sealing strip 11 makes the cabinet door 4 tighter, then the present invention is opened by the controller 5, and the heater 3 starts to heat the present invention. After heating, the heater 3 stops working, the ozone generator 6 starts to run, the ozone is full of the cabinet, and the ozone acts on the product. The staff can observe the product through the observation window 13. After the detection is completed, the exhaust fan 10 is turned on by the controller 5 , the exhaust fan 10 discharges the ozone outside the cabinet, and enters the ozone recovery box 9 through the recovery pipe 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com