Icing high precision monitoring method for electric power system power transmission line

A technology for transmission lines and power systems, applied in the direction of measuring devices, instruments, etc., can solve the problems of tension displacement sensor loss, alarm delay, broken connection, etc., and achieve the effects of convenient monitoring and management, ensuring accuracy, and fast alarm speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

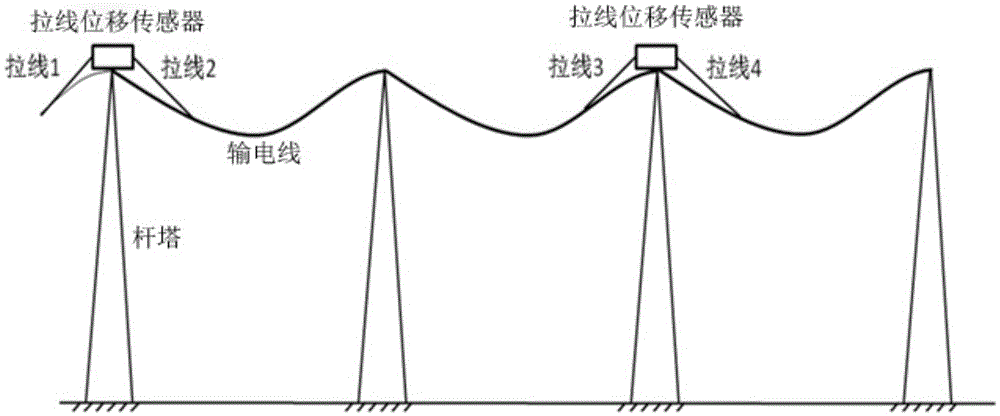

[0016] The high-precision monitoring method for icing on transmission lines in power systems described in this embodiment is specifically: firstly, use a cable displacement sensor, a temperature sensor, a brightness sensor, and a wind speed sensor to measure the degree of deformation between the transmission line and the tower, the external temperature, and the icing. Ice transparency and wind speed, and then comprehensively analyze the data measured by each sensor through the processor to determine whether ice is formed and the degree of ice formation. When the degree of ice exceeds the preset threshold, the alarm system will be triggered. Through ZigBee wireless communication The network transmits the alarm signal back to the control center. Its analysis process is as follows:

[0017] When the temperature sensor detects that the ambient temperature is lower than the preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com