Liquid nitrogen rapid-icing device

A liquid nitrogen and fast technology, used in ice making, ice making, lighting and heating equipment, etc., can solve the problems of ice cubes that cannot be made as they are used, difficulty in ensuring the melting degree of ice cubes, and increased transportation costs and difficulties. To achieve the effect of sufficient and rapid heat exchange, good ice-forming effect, and high utilization rate of cold source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

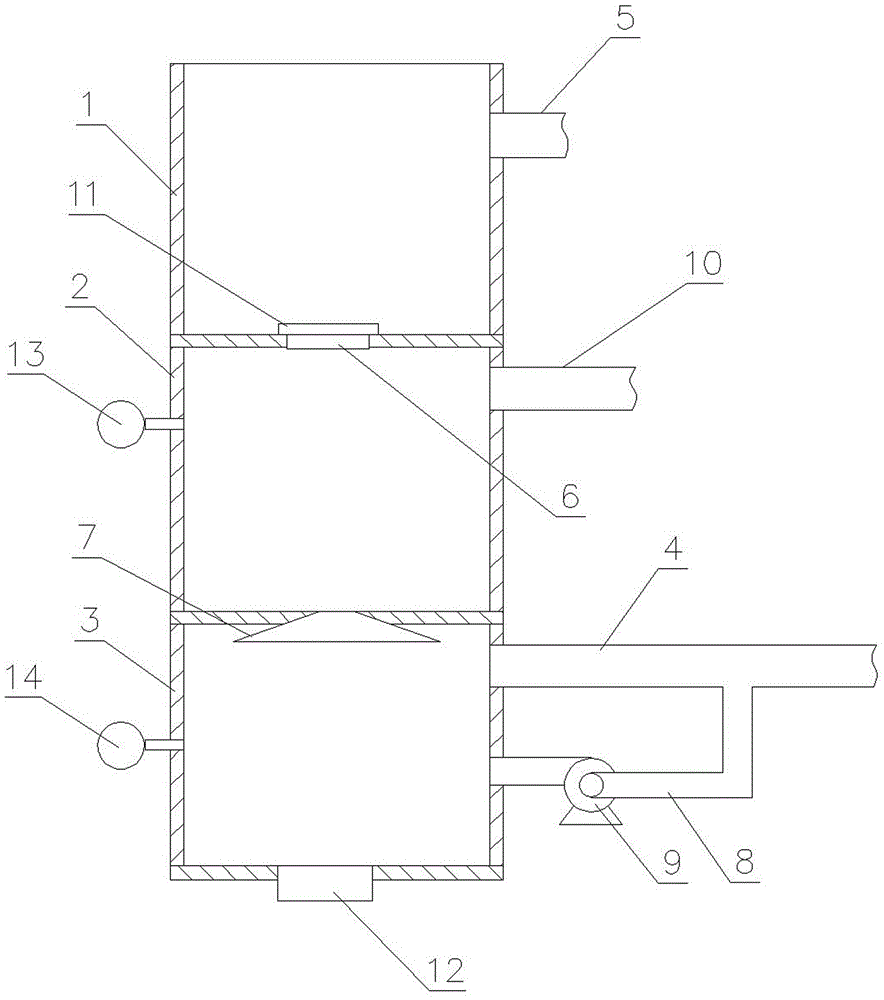

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

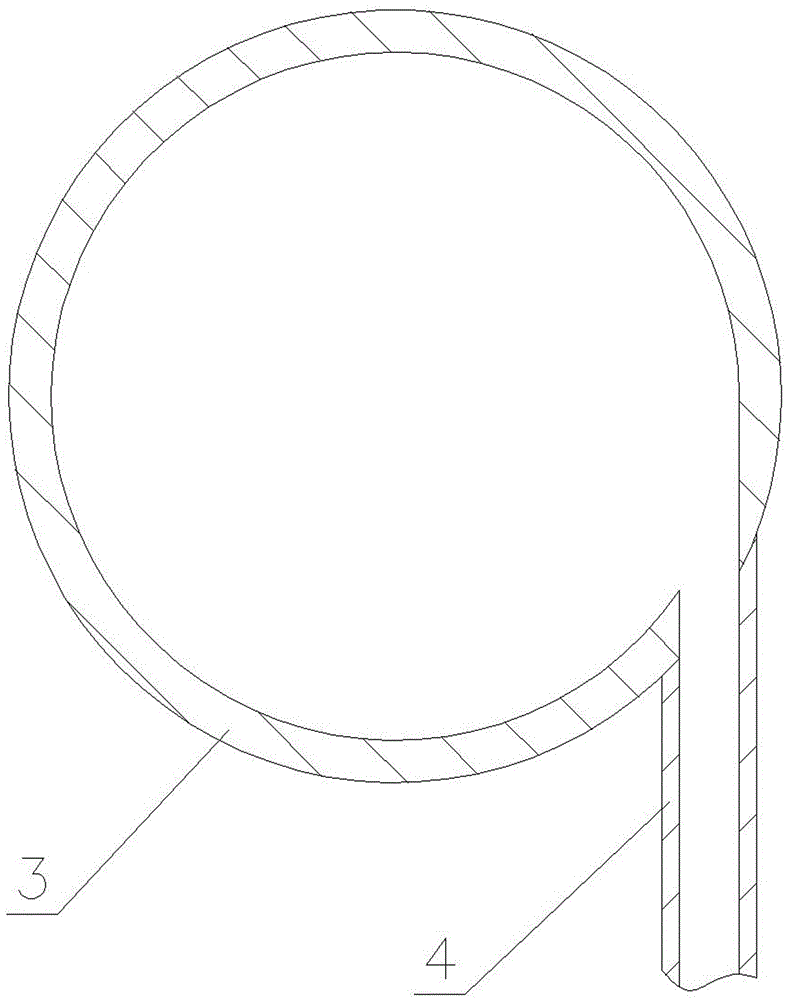

[0023] as attached figure 1 and 2 As shown, a rapid liquid nitrogen ice-making device includes a water storage tank 1, a temperature-regulating tank 2 arranged below or on the side of the water storage tank 1, an ice-making tank 3 arranged below or on the side of the temperature-regulating tank 2, and a The first low-temperature nitrogen inlet pipe 4 connected to the ice tank 3, the water storage tank 1 is used to store the fresh water or sea water needed for ice making, and the water storage tank 1 is provided with a water outlet 6 communicating with the temperature adjustment tank 2, and the water outlet 6 The water outlet 6 is provided with a switch 11 that can open and close the water outlet 6. By opening the switch 11, the water in the water storage tank 1 is controlled to flow into the temperature regulating tank 2. When the water in the temperature re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com