Nickel-titanium spring having high output force value ratio under high and low temperatures

A high-low temperature, output force technology, applied in the direction of springs, springs/shock absorbers, coil springs, etc., can solve problems such as changes, spring support balance and stability cannot be guaranteed, and achieve the effect of increasing the ratio of high and low temperature output force values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

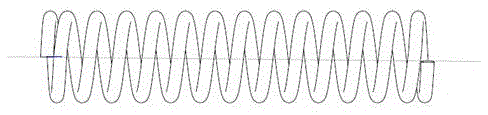

[0012] like figure 1 Shown, the nickel-titanium spring in the present embodiment is to take the nickel-titanium wire of diameter 8mm as raw material, and the nickel atom percentage content of nickel-titanium wire is 50.0%, is drawn into the wire material of 3mm, and the wire material is wound The mandrel is molded into a spiral shape, and the outer peripheral surface of the mandrel is formed into a continuous spiral groove. After the mandrel is withdrawn from the mold, the pre-shaped spring is divided and cut, and then the spring is subjected to high and low temperature training, as follows:

[0013] Place the spring in a low-temperature environment of minus 20°C to minus 50°C, which can be liquid nitrogen or low-temperature alcohol to make the spring weak, specifically satisfying that there is no recovery deformation after compressing the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com