Abrasive perforating unblocking method and device for coiled tubing

A sandblasting perforating and tubing technology, which is applied to earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of too small inner diameter of the pipe string, uncontrollable, poor controllability, etc., to improve the pass rate, The effect of strong adaptability and high passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

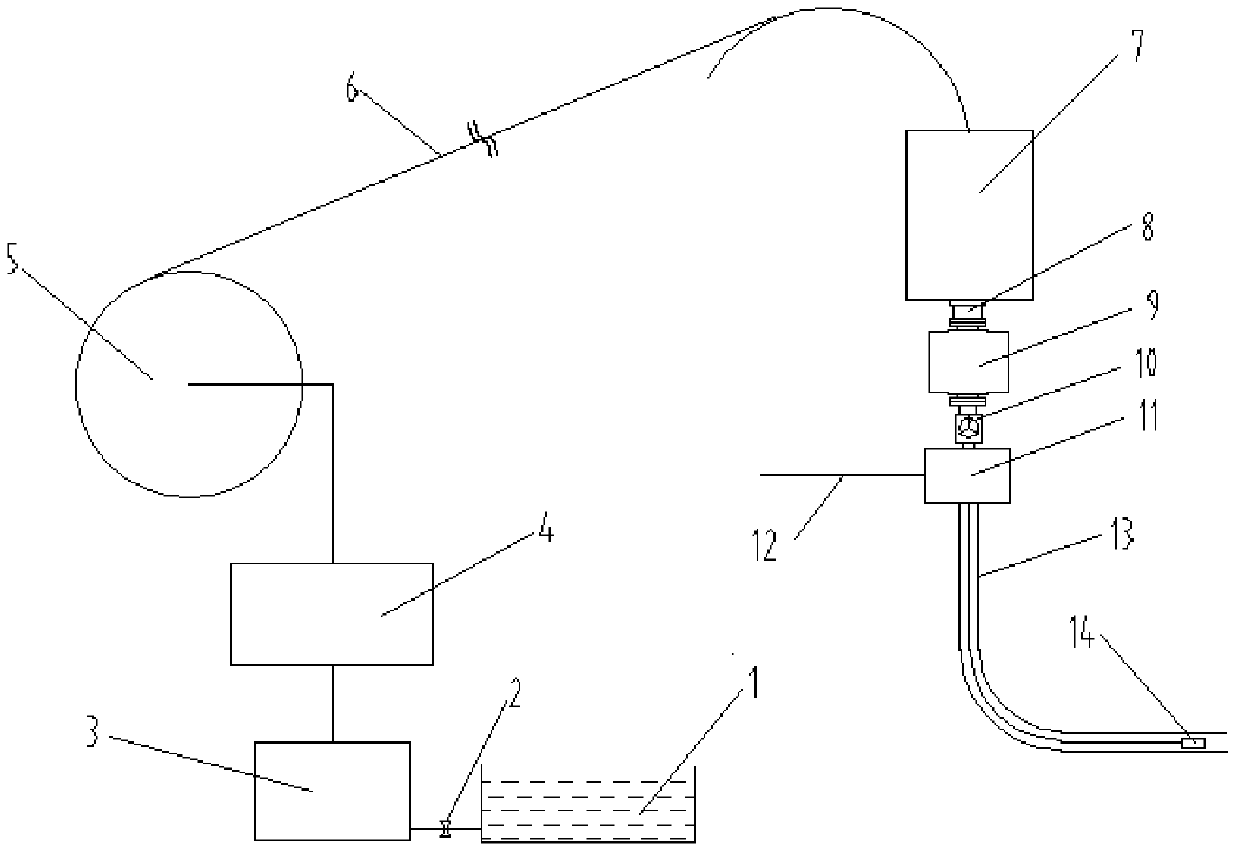

[0038] Such as figure 1 As shown, the present invention provides a coiled tubing sandblasting and perforating plugging removal device, which is used to solve the problem of plugging of production strings in the production process of oil, gas and water wells. The device includes a liquid tank 1 , a sand mixing skid 3 , high-pressure pumping equipment 4 , coiled tubing equipment 5 and an injector 14 . Sand mixing skid 3, high-pressure pumping equipment 4, and coiled tubing equipment 5 constitute ground equipment, and sand mixing skid 3 is a small sand mixing skid. The sand-carrying liquid is stored in the liquid tank 1, and the input pipeline of the sand mixing skid 3 is connected with the liquid tank 1; The input end of the high-pressure pumping equipment 4 is connected with the output pipeline of the sand mixing skid 3 . The coiled tubing equipment 5 is wound with a coiled tubing 6, the coiled tubing equipment 5 and the coiled tubing 6 are connected by a union, the high-pres...

Embodiment approach 2

[0048] Such as figure 1 As shown, the present invention also provides a method for removing plugging by sandblasting and perforating. The method uses the device for removing plugging by sandblasting and perforating in Embodiment 1. The intentional effect is the same as that of Embodiment 1, and will not be repeated here. The sandblasting and perforating plugging removal method comprises the following steps:

[0049] Step a) Set liquid tank 1, sand mixing skid 3, high-pressure pumping equipment 4 and coiled tubing equipment 5 on the ground, coiled tubing equipment 5 is wound with coiled tubing 6, and the end of coiled tubing 6 is connected with injector 14.

[0050] Step b) adding a certain proportion of abrasives to the sand-carrying liquid in the liquid tank 1 through the sand mixing skid 3 to form a uniformly mixed abrasive suspension.

[0051] Step c) pumping the abrasive suspension into the coiled tubing 6 through the high-pressure pumping equipment 4 .

[0052] Step d)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com