Modular assembly type steel body container and assembly method thereof

An assembled and modular technology, applied in containers, large containers, packaging, etc., can solve problems such as on-site pollution, and achieve the effects of avoiding pollution, easy relocation, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

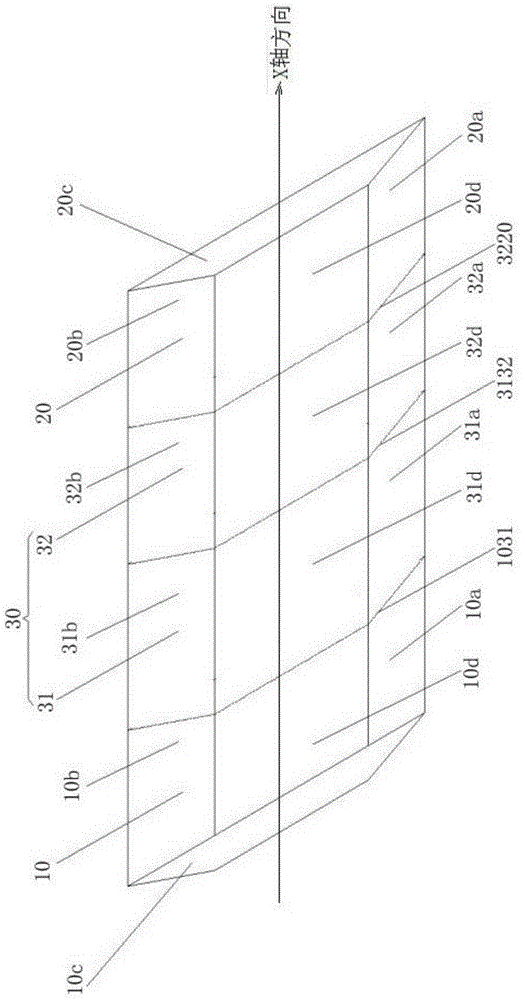

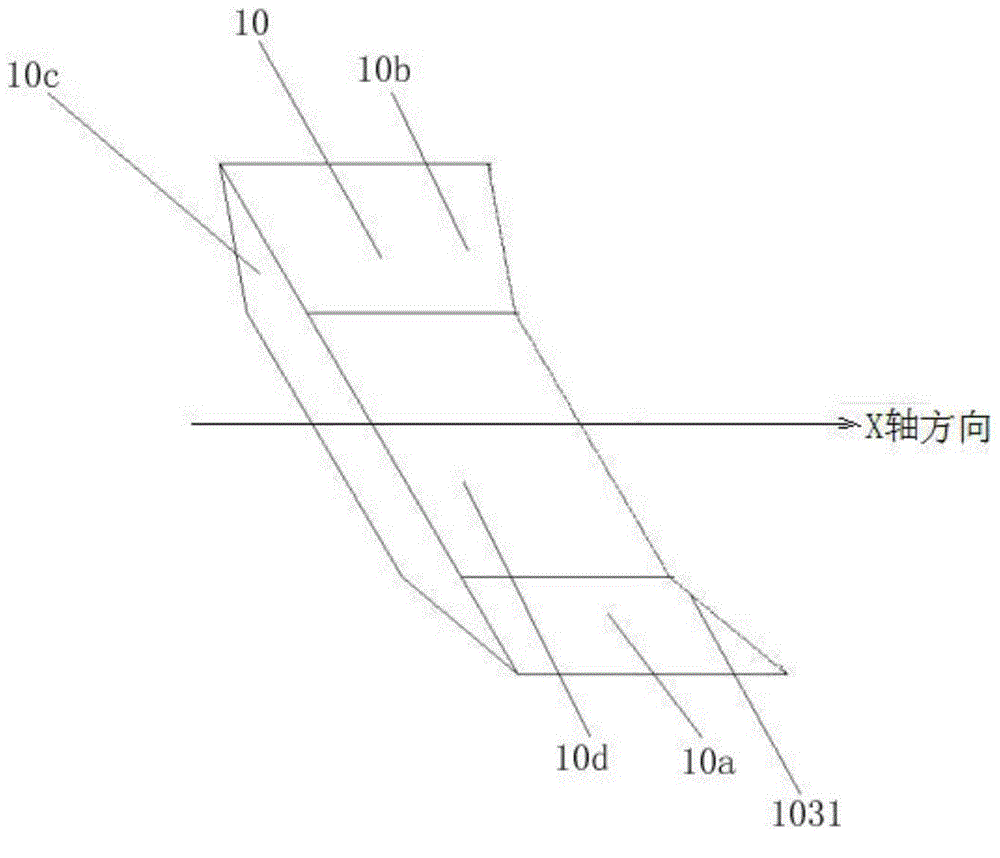

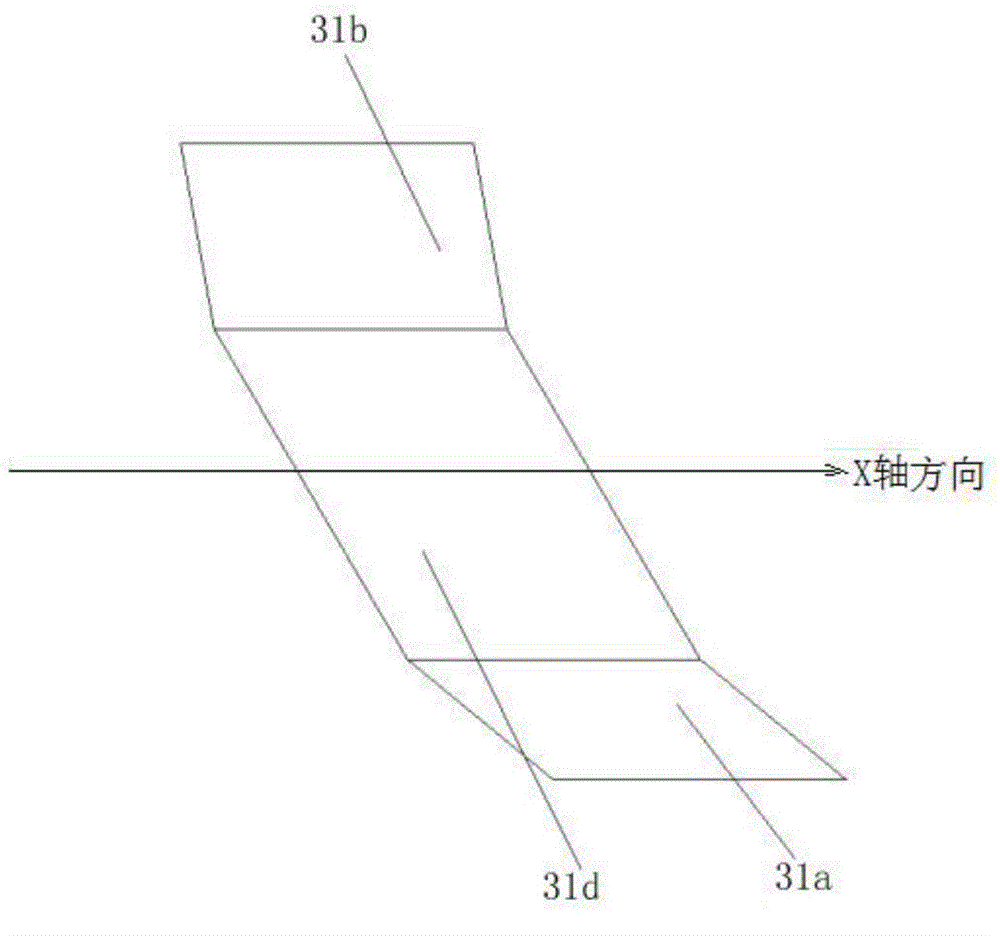

[0037] see Figure 1-Figure 4 , Figure 7 , Figure 8, the modular assembled steel container according to a preferred embodiment of the present invention, only the top end is open, and the cross-sectional shape in the direction perpendicular to the X axis is trapezoidal, including a first module 10, a third module 30, and a second module 20 and bolts 60, the first module 10, the third module, and the second module are detachably spliced together in order from left to right. The third module includes two monomers, and the monomers are detachably spliced in sequence. Together, the materials of the first module 10 , the third module 30 and the second module 20 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com