Device and method for producing low-dispersion coefficient carbon fibers

A discrete coefficient and carbon fiber technology, applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as unstable production and unresolved basic scientific problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

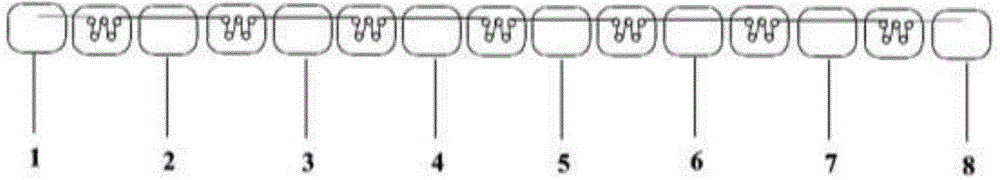

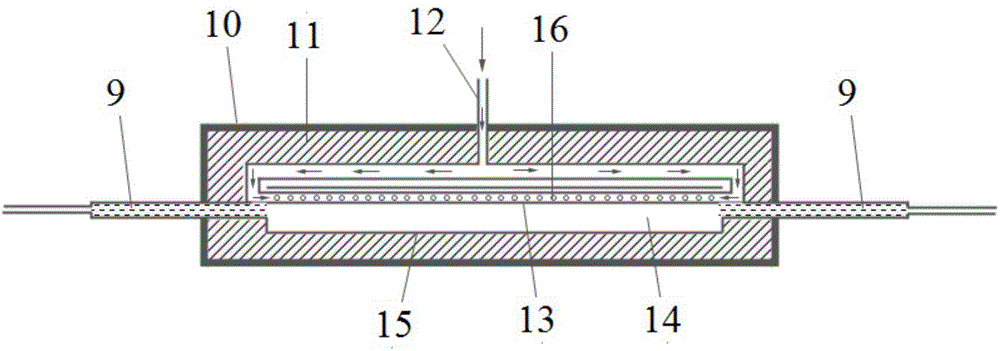

[0020] After the polyacrylonitrile precursor is uncoiled, it is pre-treated by a saturated steam device and a drying oven. The steam pressure is 0.15MPa, the residence time is 3min, and the draft ratio is 5%. The drying oven temperature is 120°C, and the drying time is 5 minutes. Then, preoxidation is carried out by gradually increasing the temperature at 180-300°C under air atmosphere, low-temperature carbonization is carried out at 300-800°C under inert gas, and high-temperature carbonization is carried out at 900-1500°C. Finally, the carbon fiber is obtained by winding, the tensile strength of the carbon fiber is 4540MPa, and the dispersion coefficient of the tensile strength is 2.15%; the tensile modulus is 257GPa, and the dispersion coefficient of the tensile modulus is 2.21%.

Embodiment 2

[0022] After the polyacrylonitrile precursor is uncoiled, it is pretreated by a saturated steam device and a drying oven. The steam pressure is 0.2 MPa, the residence time is 3 minutes, and the draft ratio is 5%. The drying oven temperature is 120°C, and the drying time is 5 minutes. Then, preoxidation is carried out by gradually increasing the temperature at 180-300°C under air atmosphere, low-temperature carbonization is carried out at 300-800°C under inert gas, and high-temperature carbonization is carried out at 900-1500°C. Finally, the carbon fiber is obtained by winding. The tensile strength of the carbon fiber is 4670MPa, and the dispersion coefficient of the tensile strength is 2.12%; the tensile modulus is 259GPa, and the dispersion coefficient of the tensile modulus is 2.09%.

Embodiment 3

[0024] After the polyacrylonitrile precursor is uncoiled, it is pre-treated by a saturated steam device and a drying oven. The steam pressure is 0.3MPa, the residence time is 3min, and the draft ratio is 5%. The drying oven temperature is 120°C, and the drying time is 5 minutes. Then, preoxidation is carried out by gradually increasing the temperature at 180-300°C under air atmosphere, low-temperature carbonization is carried out at 300-800°C under inert gas, and high-temperature carbonization is carried out at 900-1500°C. Finally, the carbon fiber is obtained by winding, the tensile strength of the carbon fiber is 4850MPa, and the dispersion coefficient of the tensile strength is 1.98%; the tensile modulus is 264GPa, and the dispersion coefficient of the tensile modulus is 1.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com