Lubricating oil and preparation method thereof

A lubricating oil and castor oil technology, applied in the field of lubricating oil, can solve the problems of easy wax formation, low output, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

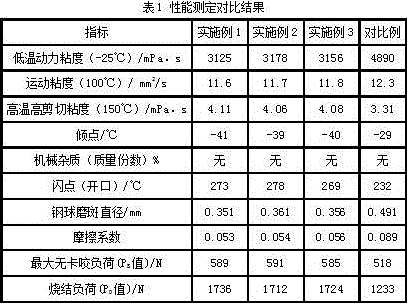

Examples

Embodiment 1

[0019] Embodiment 1: a, 42 kilograms of trimethylolpropane oleate, 6.5 kilograms of hexyl decanol, 3.5 kilograms of secondary alcohol polyoxyethylene ether (15-S-15), 5.5 kilograms of dodecane dibasic acid, the average 2.5 kg of nano-indium oxide with a particle size of 40nm is mixed with an ultrasonic stirrer, and stirred for 80-100 minutes at 66-72°C;

[0020] b. 56 kg of castor oil, 46 kg of di-isooctyl sebacate, 3.5 kg of cocoamine polyoxyethylene ether (AC-1203), 4.5 kg of triethanolamine monododecyl phosphate, and benzotriazole Add 2.5 kg to a high-speed mixer, and stir for 30 to 40 minutes at a speed of 1800 to 2000 rpm at 75 to 80 ° C;

[0021] c. Slowly add the mixed solution in step a to the mixed solution in step b, and stir for 30 to 40 minutes at a speed of 1200 to 1400 rpm; then use an ultrasonic stirrer to stir for 80 to 100 minutes, cool and serve.

Embodiment 2

[0022] Embodiment 2: a, 40 kilograms of trimethylolpropane oleate, 6 kilograms of hexyl decanol, 3 kilograms of secondary alcohol polyoxyethylene ether (15-S-15), 5 kilograms of dodecane dibasic acid, the average 2 kg of nano-indium oxide with a particle size of 40nm is mixed with an ultrasonic stirrer, and stirred for 80-100 minutes at 66-72°C;

[0023] b. 52 kg of castor oil, 45 kg of diisooctyl sebacate, 3 kg of cocoamine polyoxyethylene ether (AC-1203), 4 kg of triethanolamine monododecyl phosphate, and benzotriazole Add 2 kg to a high-speed mixer, and stir for 30 to 40 minutes at a speed of 1800 to 2000 rpm at a temperature of 75 to 80 ° C;

[0024] c. Slowly add the mixed solution in step a to the mixed solution in step b, and stir for 30 to 40 minutes at a speed of 1200 to 1400 rpm; then use an ultrasonic stirrer to stir for 80 to 100 minutes, cool and serve.

Embodiment 3

[0025] Embodiment 3: a, 44 kilograms of trimethylolpropane oleate, 7 kilograms of hexyl decanol, 4 kilograms of secondary alcohol polyoxyethylene ether (15-S-15), 6 kilograms of dodecane dibasic acid, the average 3 kg of nano-indium oxide with a particle size of 40nm is mixed with an ultrasonic stirrer, and stirred for 80-100 minutes at 66-72°C;

[0026] b. 60 kg of castor oil, 50 kg of di-isooctyl sebacate, 4 kg of cocoamine polyoxyethylene ether (AC-1203), 5 kg of triethanolamine monododecyl phosphate, and benzotriazole Add 3 kg to a high-speed mixer, and stir for 30 to 40 minutes at a speed of 1800 to 2000 rpm at 75 to 80 °C;

[0027] c. Slowly add the mixed solution in step a to the mixed solution in step b, and stir for 30 to 40 minutes at a speed of 1200 to 1400 rpm; then use an ultrasonic stirrer to stir for 80 to 100 minutes, cool and serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com