Method for mixing coal for solid-state deslagging coal chemistry industry device

A technology of slagging coal and coal blending, which is applied in the petroleum industry, coking ovens, etc., can solve the problems of low utilization rate, achieve the effects of reducing raw material costs, saving costs, and increasing melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Maiduo coal from Maiduoshan Coal Mine in Ningdong Mining Area of Ningxia was used as raw material coal.

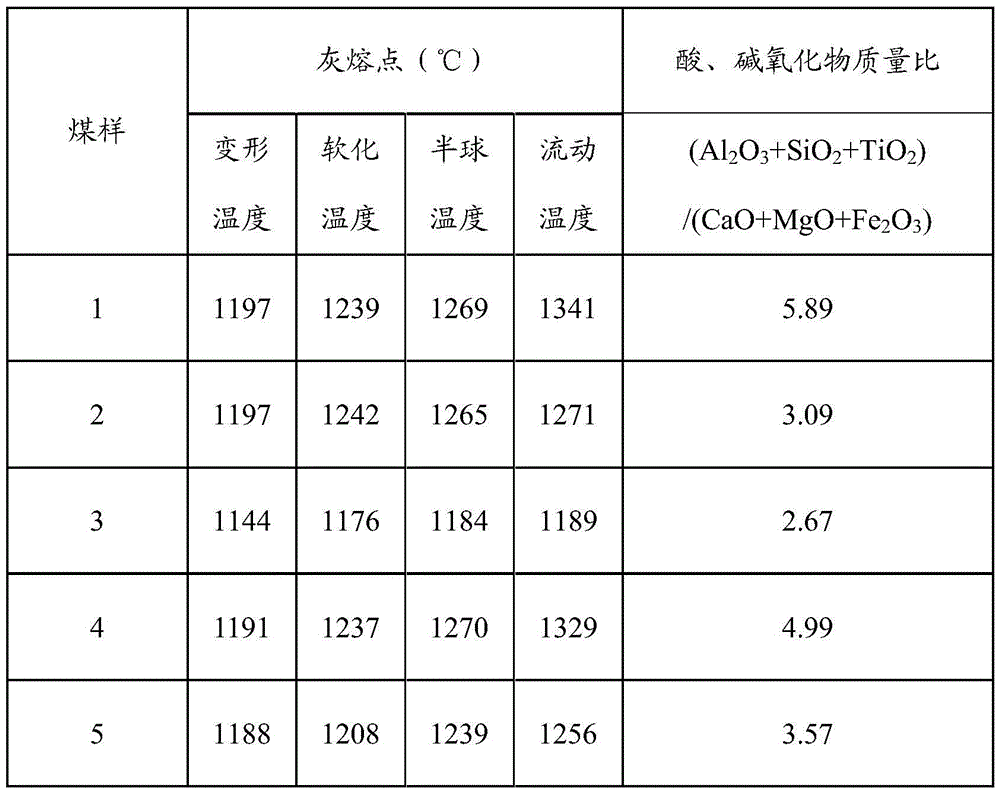

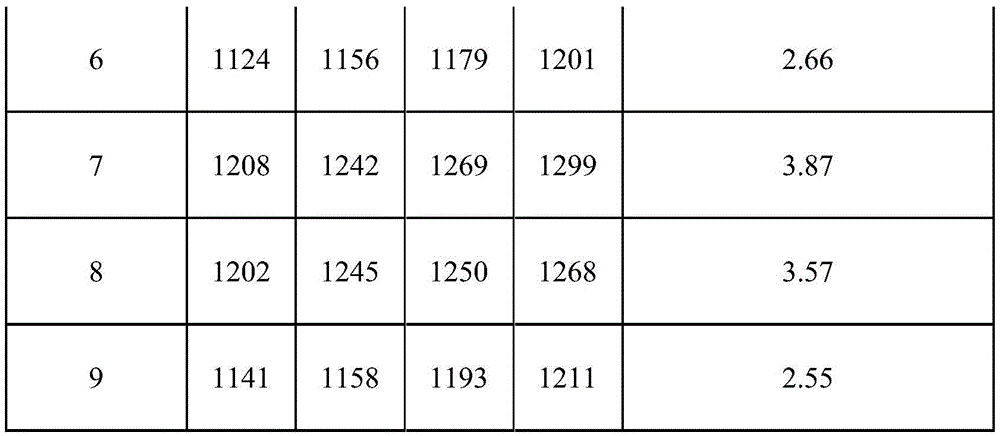

[0040] (1) Detect the melting temperature of the coal ash of the Maiduo coal sample, that is, obtain the coal ash deformation temperature, softening temperature, hemispherical temperature and flow temperature of the standard coal ash sample respectively. The specific data are shown in Table 2:

[0041] Table 2 Ash melting temperature of coal ash samples, °C

[0042]

deformation temperature

softening temperature

hemispheric temperature

flow temperature

Maiduoshan coal sample

1032

1045

1067

1068

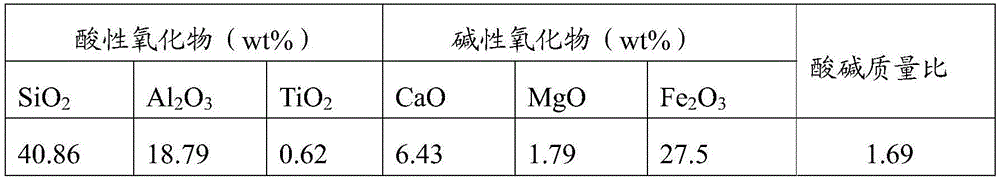

[0043] (2) Determination of the chemical composition of coal ash, mainly including acidic oxide SiO 2 、Al 2 o 3 、TiO 2 and basic oxides CaO, MgO, Fe 2 o 3 content, and calculate the ratio of the total weight of acidic oxides to the total weight of basic oxides. The specific data are shown in Table 3:

[004...

Embodiment 2

[0052] Jinfeng coal from Jinfeng Coal Mine in Ningdong Mining Area of Ningxia is used as raw material coal.

[0053] (1) Detect the melting temperature of the coal ash of the Goldwind Coal sample, that is, obtain the coal ash deformation temperature, softening temperature, hemispherical temperature and flow temperature of the standard coal ash sample respectively. The specific data are shown in Table 5:

[0054] Table 5 Ash melting temperature of coal ash sample, ℃

[0055]

deformation temperature

softening temperature

hemispheric temperature

flow temperature

Jinfeng coal sample

1102

1146

1152

1161

[0056] (2) Determination of the chemical composition of coal ash, mainly including acidic oxide SiO 2 、Al 2 o 3 、TiO 2 and basic oxides CaO, MgO, Fe 2 o 3 content, and calculate the ratio of the total weight of acidic oxides to the total weight of basic oxides. The specific data are shown in Table 6:

[0057] Tab...

Embodiment 3

[0064] The Meihuajing coal from the Meihuajing Coal Mine in the Ningdong Mining Area of Ningxia is used as the raw material coal.

[0065] (1) Detect the melting temperature of the coal ash of the Meihuajing coal sample, that is, obtain the coal ash deformation temperature, softening temperature, hemispherical temperature and flow temperature of the standard coal ash sample respectively. The specific data are shown in Table 8:

[0066] Table 8 Ash melting temperature of coal ash sample, ℃

[0067]

deformation temperature

softening temperature

hemispheric temperature

flow temperature

Meihuajing coal sample

1081

1093

1111

1148

[0068] (2) Determination of the chemical composition of coal ash, mainly including acidic oxide SiO 2 、Al 2 o 3 、TiO 2 and basic oxides CaO, MgO, Fe 2 o 3 content, and calculate the ratio of the total weight of acidic oxides to the total weight of basic oxides. The specific data are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com