Polysiloxane functionalized carbon dots and preparation method thereof, and application of polysiloxane functionalized carbon dots

A polysiloxane, functionalization technology, applied in chemical instruments and methods, dyeing organosilicon compound treatment, energy-saving lighting, etc., can solve the problem of limited doping concentration of carbon dots, and achieve improved compatibility and good white light Good quality and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add isocyanate propyl methyl silicone oil and citric acid ethanol solution into a high-pressure reactor, and react at 170°C for 4 hours; after column separation, a concentrated isocyanate propyl methyl silicone oil carbon-dot ethanol solution with known carbon-dot concentration is obtained. Isocyanate propyl methyl silicone oil carbon dots are directly coated on the blue LED chip and cured. The blue light is combined with the emission of carbon dots to obtain white light.

[0041] In order to obtain isocyanate propyl methicone functionalized carbon dots with higher fluorescence quantum yield, different molecular weights of isocyanate propyl methicone were selected during the reaction, as shown in Table 1. The results show that the quantum efficiency is about 16%.

[0042] The quantum yield of carbon dots prepared by isocyanate propyl methyl silicone oil of different molecular weights in table 1

[0043]

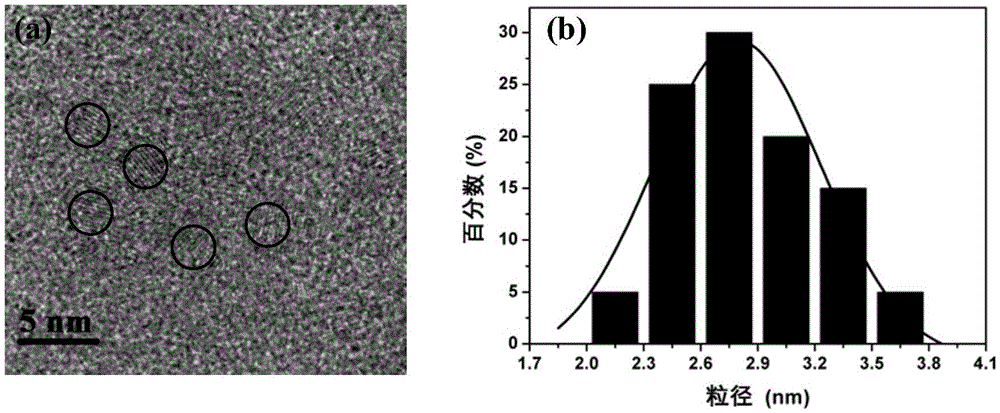

[0044] figure 1 It shows that the carbon dots are circular ...

Embodiment 2

[0053] Add isocyanate propyl methyl silicone oil ethanol solution into the high-pressure reaction kettle, then add malic acid ethanol solution, and magnetically stir to obtain a blended solution; put the reaction kettle into a blast oven, and react at 170°C for 4 hours; obtain isocyanate after extraction and separation Propyl methyl silicone carbon dot ethanol solution.

Embodiment 3

[0055] Add isocyanate propyl methyl silicone oil ethanol solution into the high-pressure reaction kettle, then add malic acid ethanol solution, and magnetically stir to obtain a blended solution; put the reaction kettle into a blast oven, and react at 150°C for 16 hours; obtain isocyanate after extraction and separation Propyl methyl silicone carbon dot ethanol solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com