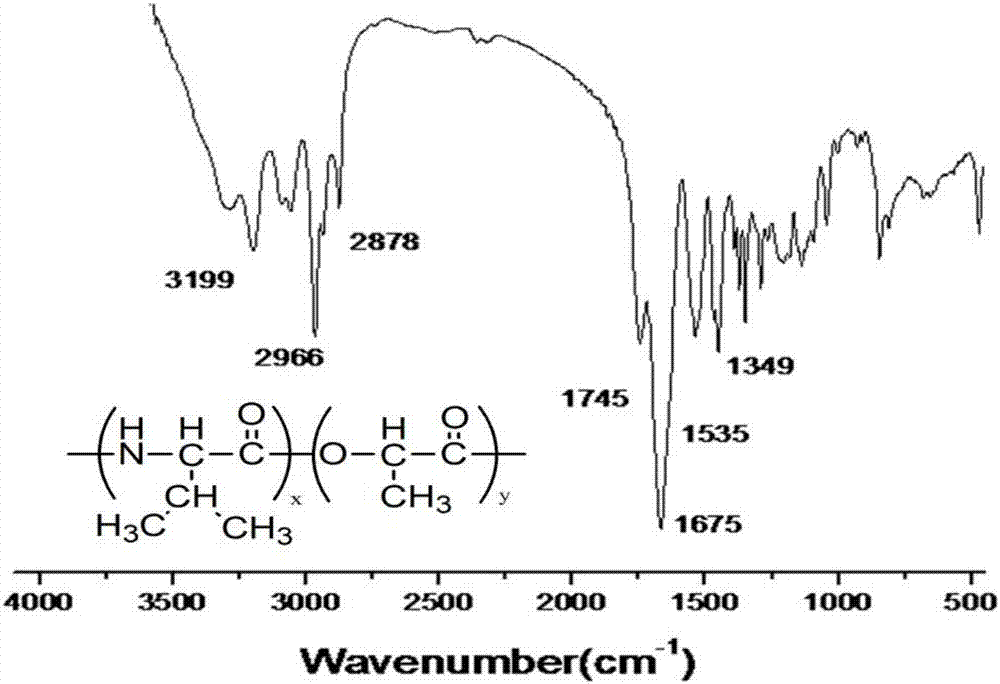

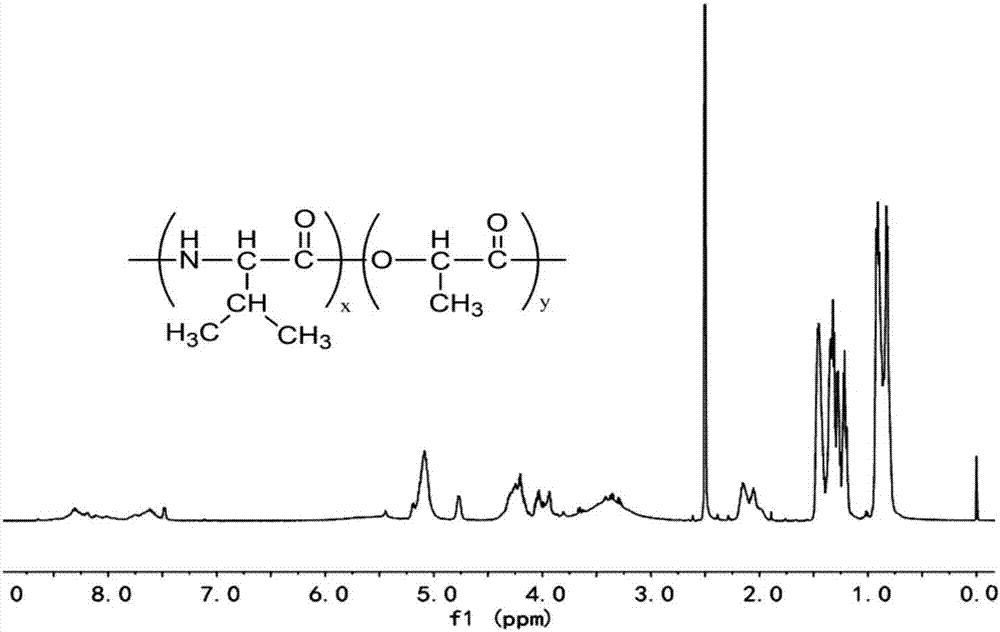

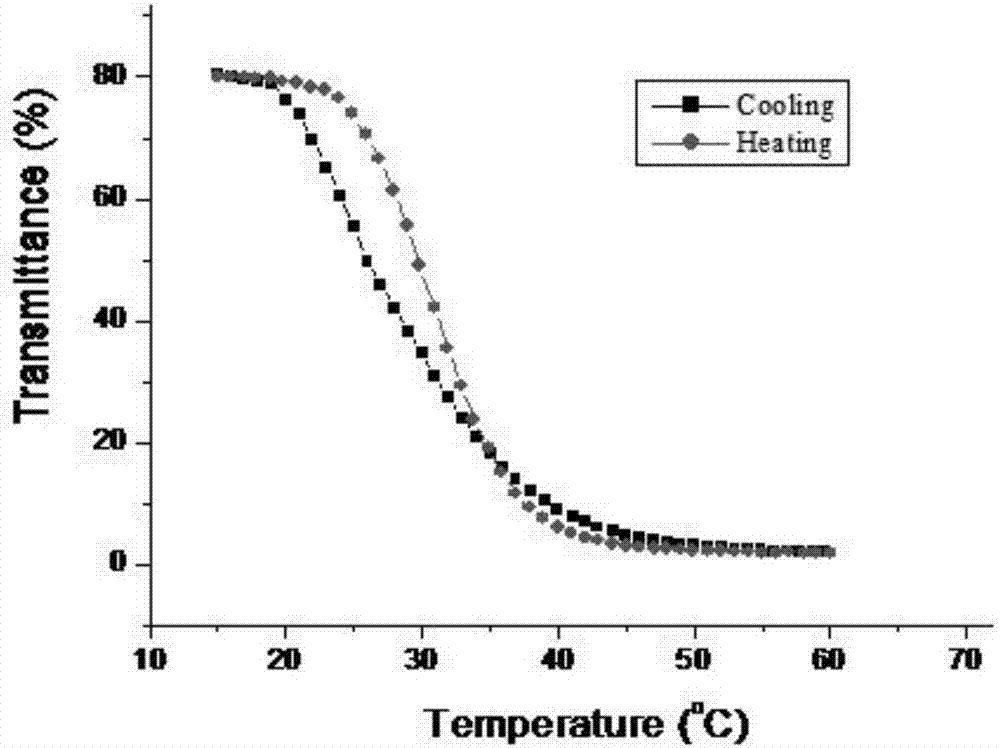

Thermosensitive poly(lactic acid-valine) material and preparation method thereof

A valine and temperature-sensitive technology, which is applied in the field of temperature-sensitive poly(lactic-valine) materials and their preparation, can solve the problem of not being able to have both biocompatibility, biodegradability and temperature-sensitive properties, single, etc. problem, to achieve the effect of excellent biodegradability and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dehydration stage

[0042] In a microwave reactor (such as CEM microwave synthesizer, DISCOVER SP), put 5.0 g of lactic acid in a 100 mL long-necked flask, and put a magnetic stirring bar. React at a vacuum of 0.06 MPa and a temperature of 120° C. for 30 minutes to remove free water in the reaction solution. Then, add 0.6% SnCl in the reaction flask 2 and p-toluenesulfonic acid as a reaction catalyst, reacted for 45 minutes at a vacuum of 0.08MPa and a temperature of 160°C, SnCl 2 And the addition of p-toluenesulfonic acid is 0.6%, calculated with the mass of lactic acid.

[0043] (2) Polymerization stage

[0044] 6.0 g of valine was added, and the reaction was continued at a vacuum of 0.08 MPa and a temperature of 170° C. for 30 minutes.

[0045] (3) Insulation stage

[0046] The reaction was maintained for 60 minutes at a vacuum of 0.08 MPa and a temperature of 160°C. After the reaction temperature dropped to 50°C, fully dissolve it with 6mL of anhydrous met...

Embodiment 2

[0053] (1) Dehydration stage

[0054] In a microwave reactor (such as CEM microwave synthesizer, DISCOVER SP), put 5.0 g of lactic acid in a 100 mL long-necked flask, and put a magnetic stirring bar. React at a vacuum of 0.04 MPa and a temperature of 110° C. for 35 minutes to remove free water in the reaction solution. Then, add 0.6% SnCl in the reaction flask 2 With p-toluenesulfonic acid as a reaction catalyst, the vacuum was 0.06MPa, and the temperature was 158°C for 50 minutes.

[0055] (2) Polymerization stage

[0056] 6.0 g of valine was added, and the reaction was continued at a vacuum of 0.06 MPa and a temperature of 165° C. for 40 minutes.

[0057] (3) Insulation stage

[0058] The reaction was maintained for 70 minutes at a vacuum of 0.06 MPa and a temperature of 158°C. After the reaction temperature drops to 40°C, fully dissolve it with 6mL of anhydrous methanol, and then add it dropwise into 160mL of diethyl ether under stirring, a yellowish precipitate precip...

Embodiment 3

[0063] (1) Dehydration stage

[0064] In a microwave reactor (such as CEM microwave synthesizer, DISCOVER SP), put 5.0 g of lactic acid in a 100 mL long-necked flask, and put a magnetic stirring bar. React for 40 minutes at a vacuum of 0.05 MPa and a temperature of 130° C. to remove free water in the reaction solution. Then, add 0.6% SnCl in the reaction flask 2 and p-toluenesulfonic acid as a reaction catalyst, and reacted for 58 minutes at a vacuum of 0.07 MPa and a temperature of 168°C.

[0065] (2) Polymerization stage

[0066] 6.0 g of valine was added, and the reaction was continued at a vacuum of 0.07 MPa and a temperature of 172° C. for 50 minutes.

[0067] (3) Insulation stage

[0068] The reaction was maintained for 65 minutes at a vacuum of 0.07 MPa and a temperature of 164°C. After the reaction temperature drops to 45°C, fully dissolve it with 6mL of anhydrous methanol, and then add it dropwise into 160mL of diethyl ether under stirring, and a yellowish precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com